The Xerox WorkCentre 3210 is based on a 24/28ppm (depending on the model), 1200 dpi multifunction engine. These machines

can print/copy/fax and scan all with a first page out in less than 8.5 seconds.

The standard cartridge (Xerox part #106R01485) is rated for 2,000 pages. The high yield cartridge (#106R01486) is rated for

4,100 pages. As with most cartridges these days the cartridge has a chip and it has to be replaced each cycle.

The #106R01485 cartridge has a list price of $69.95* USD, and the #106R01486 has a list price of $95.95* USD.

*Pricing, in U.S. American Dollars, is current as of June 2011.

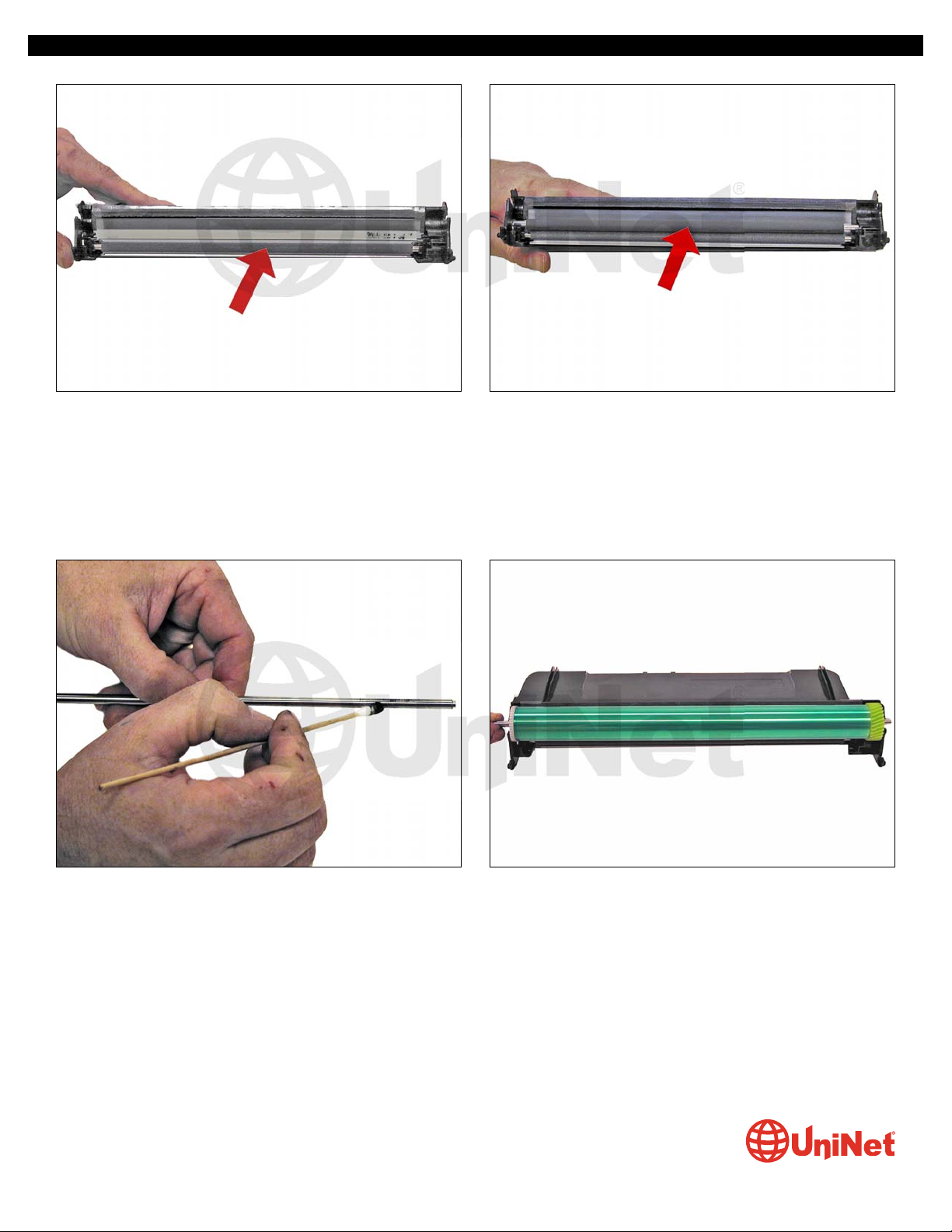

These cartridges do not have a drum cover and come new with a piece of heavy paper taped around the cartridge as pictured

above. All new cartridges opened so far have shown some toner leakage on the drum that would have shown on any prints for at

least a few pages.

Cartridge troubleshooting will be listed at the end of these instructions.

REQUIRED TOOLS

1. Toner approved vacuum

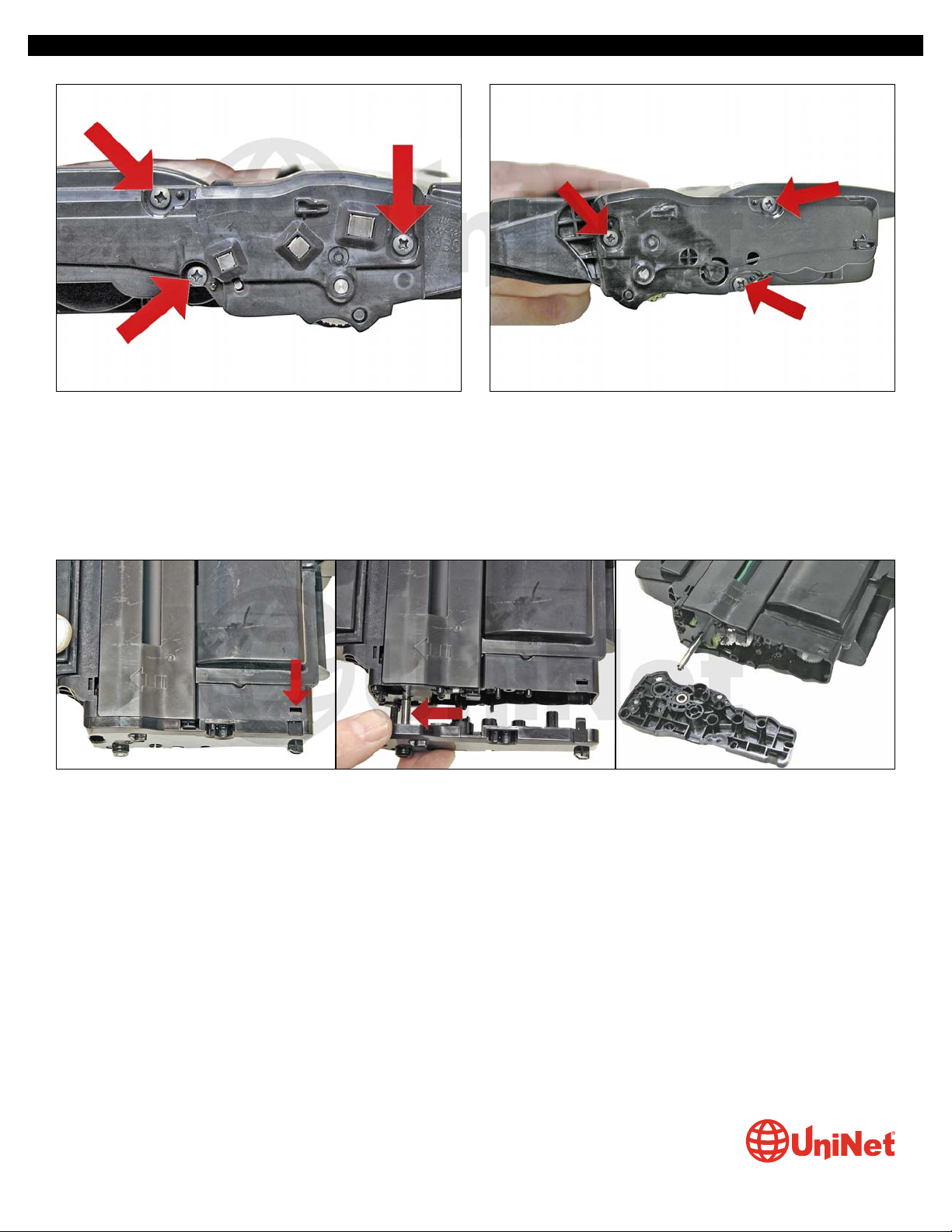

2. A small common screwdriver

3. A Phillips head screwdriver

4. Needle nose pliers

REQUIRED SUPPLIES

1. Toner for use in Xerox WorkCentre 3210

2. New replacement chip

3. Conductive grease

4. 99% isopropyl alcohol

5. Drum lubricating powder

XEROX WORKCENTRE 3210 •3220 TONER CARTRIDGE REMANUFACTURING INSTRUCTIONS

REMANUFACTURING THE XEROX

WORKCENTRE 3210/3220 TONER CARTRIDGE

By the Technical Staff at UniNet

© 2011 UniNet Imaging Inc. All trademark names and artwork are property of their respective owners. Product brand names mentioned are intended to show compatibility only.

UniNet

Imaging

does

not

warrant

downloaded

information.

Unauthorized

sale,

reproduction

or

distribution

of

this

article

is

prohibited.

For

additional

support,

please

contact

[email protected]www.uninetimaging.com