Page 8

DPB1U & DPG1U SERIES

OPERATING MANUAL

POWERING TECHNOLOGY

Manual No. DPB-DPG-4 dpb_dpg-man-rev4-0317.indd

7.0 SPECIFICATIONS

The following specications are typical at 25°C unless otherwise noted.

INPUT / OUTPUT

Panel Capacity ...........................................See Panel Conguration Table

Conguration

DPB1U

Single Bus .............................................................. 1 to 12 Breakers

Dual Bus..........................................................1 to 6 Breakers Each

DPG1U

Single Bus ...........................................................1 to 20 GMT Fuses

Dual Bus.....................................................1 to 10 GMT Fuses Each

Breaker/Fuse Capacity1 ............................................................. ½A to 50A

Voltage2

48V Nominal..........................................................................42-60VDC

24V Nominal..........................................................................21-30VDC

12V Nominal.......................................................................10.5-15VDC

Polarity.....................................................................POLARITY NEUTRAL

ALARMS

Alarm Indicator .....................................................Dual-Color LED Per Bus

LED Status Indication........................................................Green = Normal

Red = Alarm

O = No Power

Alarm Connections.............................One Form C Relay Contact Per Bus

SAFETY STANDARDS..............................................UL1950, UL60950-1

CAS22.2 No.950-1, EN60950-1

ENVIRONMENTAL

Operating Temp. Range ..................................................... -10°C to +70°C

Storage Temp. Range........................................................ -40°C to + 85°C

Humidity........................................................0% to 95%, Non-Condensing

PHYSICAL SPECIFICATIONS

Case Material ......................................................................................Steel

Finish............................................................................Powder Coat Black

Dimensions3, Inches (mm)................................1.75 H x 19.00 W x 9.00 D

(44.5 x 483 x 229)

Weight ....................................................................... 10.30 lbs. ( 4.67 kg.)

Rack Mounting Width ....................................................... 19 or 23 Inches

CONNECTIONS

Input Connections.......................................Crimp Type Lug or ¼ - 20 Stud

Output Connections

1-30A.................................................. Barrier Terminal Strips, No. 6-32

40A-50A............................................ Barrier Terminal Strips, No. 10-32

Chassis Ground Connection..................................................No. 8-32 Stud

Fail Alarm Connections...........................................045” sq. Wirewrap Pins

NOTES: 1. See tables for available breaker & fuse sizes.

2. See Ordering Guide to specify voltage.

3. For units with fail safe option the case depth is 10.44 inches (265mm).

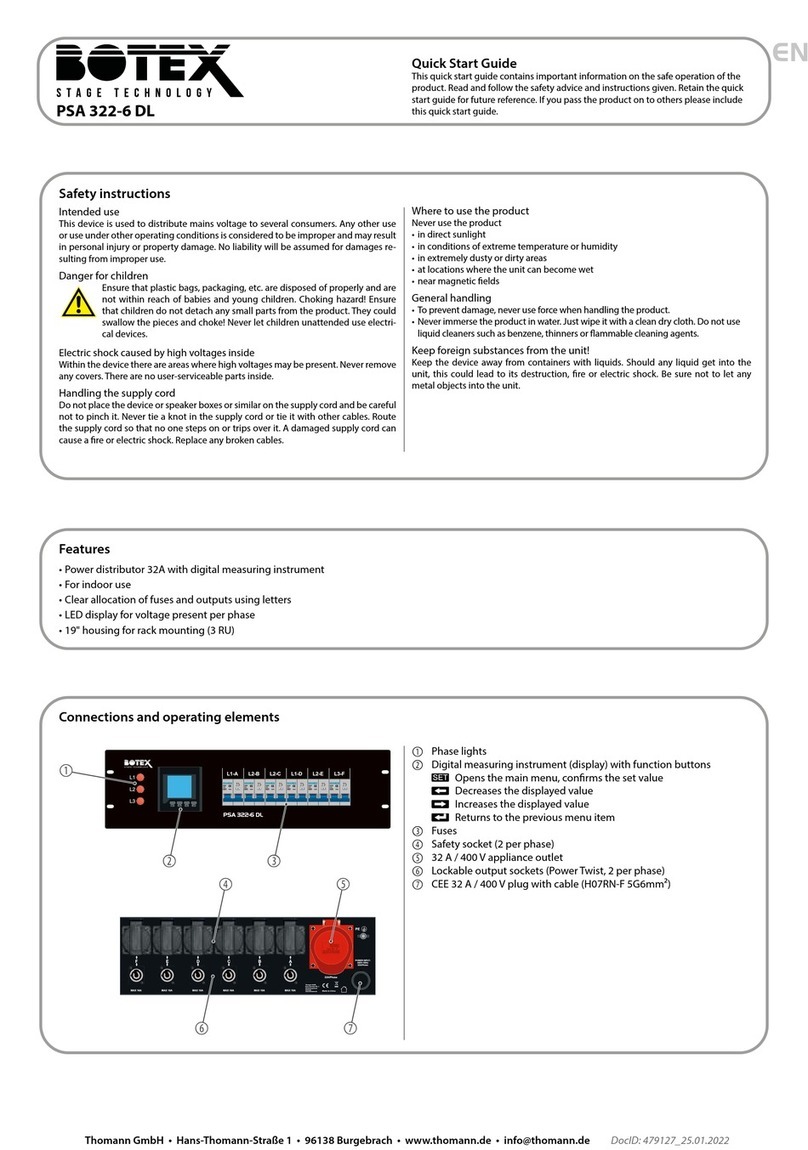

8.0 FRONT PANEL DESCRIPTION

The front panel of the DPB1U, shown in Figure 3 below, consists of the A and B sides and a center

section. TheAand B sides can each accommodate up to 6 hydraulic magnetic circuit breakers rated

from 1A to 50A.

Alarm LEDs

B Input

¼-20 Studs

BAT

RTN

BAT

RTN

1 2 3 4 5 6 7 8 9 10

A B

ALARM

A Side Breakers B Side Breakers

A Outputs

6-32 Terminal Strip

B Outputs

6-32 Terminal Strip A Input

¼-20 Studs

BAT

RTN

BAT

RTN

1 2 3 4 5 6 7 8 9 10

B SIDE A SIDE

NO-C-NC NO-C-NC

5

6

3

4

1

2

OFF

OON

I

15

OFF

OON

I

15

OFF

OON

I

15

OFF

OON

I

15

OFF

OON

I

15

OFF

OON

I

15

5

6

3

4

1

2

OFF

OON

I

15

OFF

OON

I

15

OFF

OON

I

15

OFF

OON

I

15

OFF

OON

I

15

OFF

OON

I

15

17.12 (434.9)

1.74

(44.2)

REAR VIEW

FRONT VIEW

Case depth: 8.94 (227.1)

2.28

(57.8)

Clear Perspex

Safety Cover

Figure 3. DPB1U Front Panel View

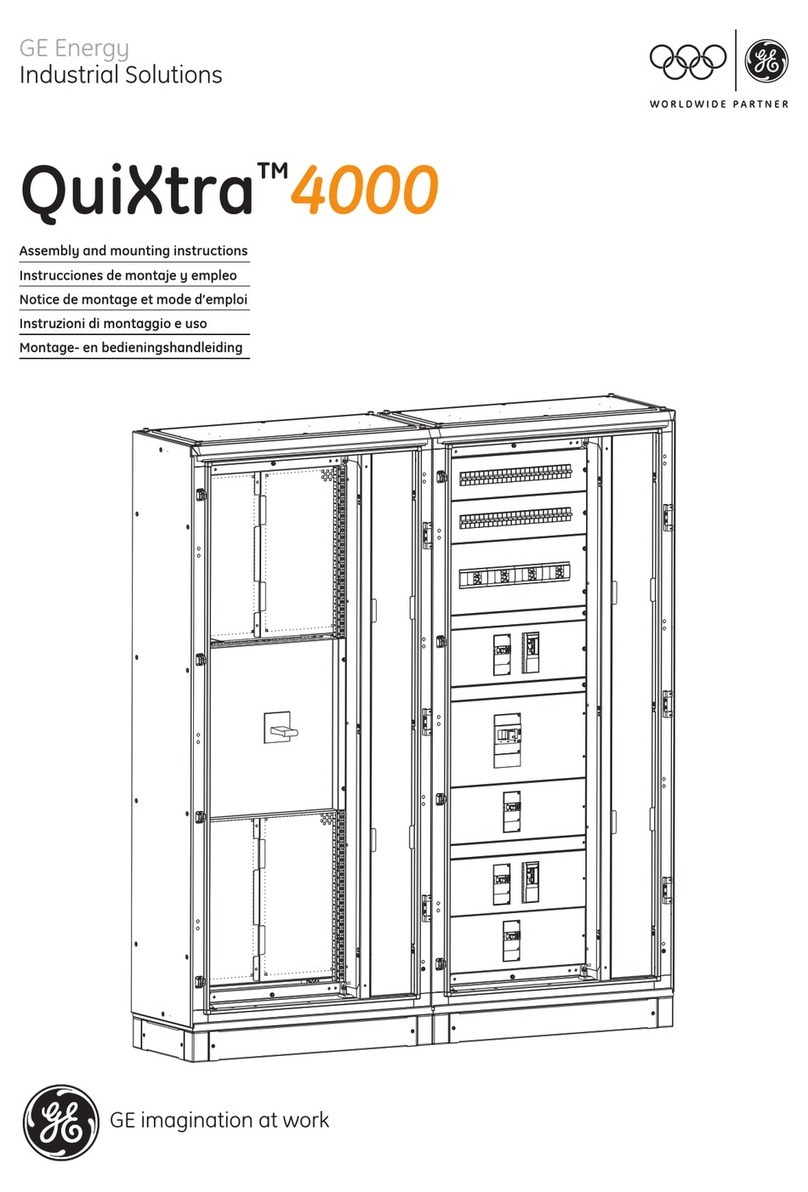

The front panel of the DPG1U, shown in Figure 4 below, consists of the A and B sides and a center

section. TheA and B sides can each accommodate up to 10 GMT Fuses rated from ½Ato 12A.

Alarm LEDs

A B

ALARM

A Side Fuses B Side Fuses

1 10 1 10

17.12 (434.9)

FRONT VIEW

1.74

(44.2)

Figure 4. DPG1U Front Panel View

In both cases the center section has two green/red LEDs, one for the A side (left) and the other for

the B side (right). At the bottom of this center section is a slot for a wallet and designator card. This

card permits the recording of each output circuit by number.