7

Look foward to it.

Assembly / preparation

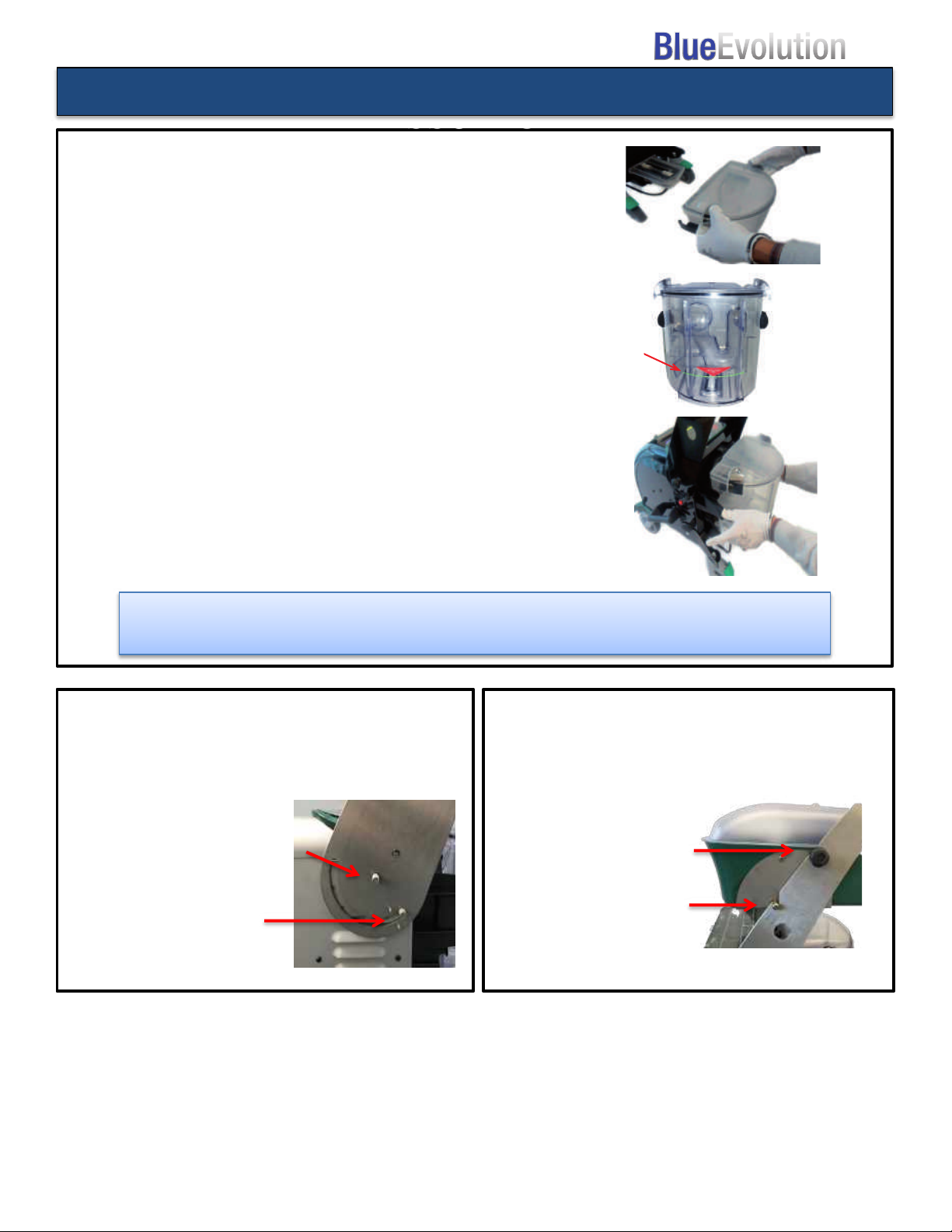

Filling the filter bowl

Your appliance is fitted with a hygienic water filter. You must

fill the filter bowl with water before starting, in order to bind

the extracted dirt in the water and to clean the suctioned air

in the water bath as well.

• Loosen the clips on the right and left of the filter bowl and

remove from its slot.

• Open the cover on the filter bowl by pushing off the rele-

vant clips.

• Fill with tap

water

up to the

green line

(approx.

2.0 litres).

• Re-insert the filter bowl, ensuring the switch cam on the

cover is in the correct position.

WARNING:

The appliance can suck in up to approx. 1.5 litres of liquid.

If you exceed this amount, the fill level sensor will stop suc-

tion automatically and LED D (page 2) on the display will

flash.

INFO:

If you only wish to suction liquid, such as accidental water

spills, it is not necessary to fill the appliance's filter bowl with

water.

When sucking liquids, the MAX. capacity in the container is

approx. 4 litres.

Inserting the steam suction hose

• Insert the connector of the steam suction hose into the

socket until you hear the click of the safety hook.

• To remove the hose from the appliance, press release but-

ton A and pull on the connector.

A

½gallon

capacity

for each

tank

ExtractionSteam

7

Look foward to it.

Assembly / preparation

Filling the filter bowl

Your appliance is fitted with a hygienic water filter. You must

fill the filter bowl with water before starting, in order to bind

the extracted dirt in the water and to clean the suctioned air

in the water bath as well.

• Loosen the clips on the right and left of the filter bowl and

remove from its slot.

• Open the cover on the filter bowl by pushing off the rele-

vant clips.

• Fill with tap

water

up to the

green line

(approx.

2.0 litres).

• Re-insert the filter bowl, ensuring the switch cam on the

cover is in the correct position.

WARNING:

The appliance can suck in up to approx. 1.5 litres of liquid.

If you exceed this amount, the fill level sensor will stop suc-

tion automatically and LED D (page 2) on the display will

flash.

INFO:

If you only wish to suction liquid, such as accidental water

spills, it is not necessary to fill the appliance's filter bowl with

water.

When sucking liquids, the MAX. capacity in the container is

approx. 4 litres.

Inserting the steam suction hose

• Insert the connector of the steam suction hose into the

socket until you hear the click of the safety hook.

• To remove the hose from the appliance, press release but-

ton A and pull on the connector.

A

ON/OFF

2) Add water to the vacuum

collection tank:

ØAdd water to fill line

ØAttached lid to collection tank before

installing

vLid must sit flush on the collection tank

and in the locked into position

1) Add water to reservoir tanks:

ØRemove tank caps and add water to

the steam and extraction tanks

ØReplace tank caps

Blue Evolution is ready when:

ØTemperature ≥330 ℉

ØIt will take 10 minutes for the steamer to

heat and reach working temperature after

powering on

5) Insert Hose:

ØLock front wheels

ØInsert the hose and press until you hear

it click

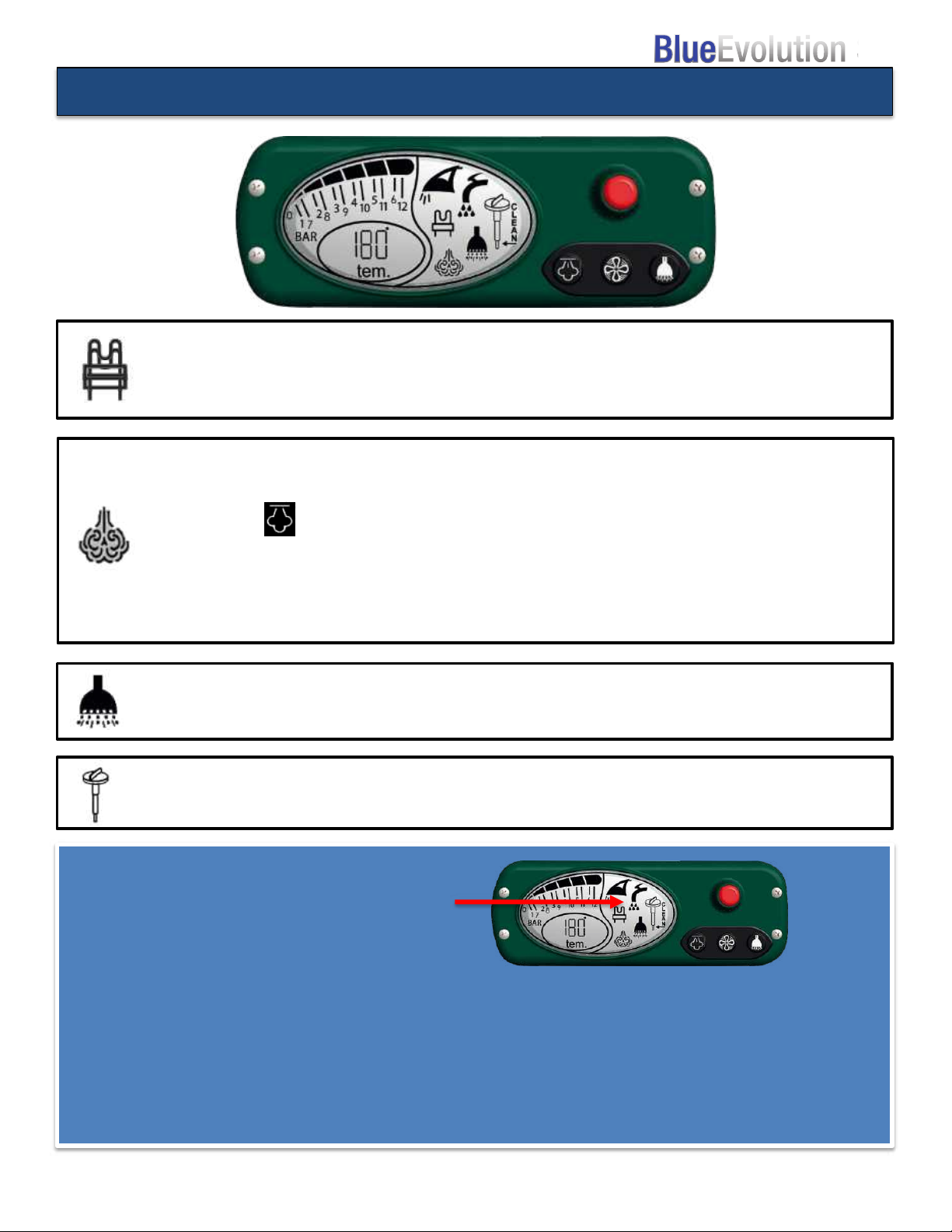

6) Steam Control:

ØUnlock the trigger by pressing red

button on hose handle

ØSqueeze trigger

7) Adjust Steam Pressure:

ØPush and hold the button to

increase or decrease steam pressure

5

3) Plug into electrical outlet:

ØThe Blue Evolution should be the

ONLY appliance plugged into the

electrical outlet

Extension Cord

ØUse only a 12 gauge / 15AMP rated or

higher extension cord

Ø25ft maximum length

4) Push ON/OFF button:

This symbol will flash during operation

indicating the Blue Evolution is heating.

9

Look foward to it.

Start-up steam with hot water module Start-up suction

The soaking effect and, thus, cleaning performance can be

increased for heavy soiling by switching the hot water mo-

dule to steam.

INFO:

Do not use on sensitive surfaces or materials.

Switching on “hot water module”

Press button Con the control panel to activate the hot wa-

ter module. The symbol Non the display begins to flash.

Pressing button

T4

on the handle for the hot water module

switches the function on and symbol Non the display stays

illuminated.

Always use button

T4

on the handle to switch the hot water

module on and off.

T3

T4

The "hot water module" flow-through can be adjustet, by

pressing the button

Cin 10% increments. This is indicated

between 010 an 100 in the display.

Display shows 010 = 10% minimum amount of hot water

Display shows 100 = 100% maximum amount of hot water

Suction

Press button Bon the display to activate suction.

LED Dfor suction turns red. (Suction mode 3 = max.)

Press button

T3

on the handle to switch on suction.

Briefly press button

T5

+ or

T5

on the side to vary suction

power.

MIN = LED Dturns green

MED = LED Dturns orange

MAX = LED Dturns red

Press button

T3

briefly to turn suction off again.

INFO:

As there is liquid in the hose and in the extension pipes du-

ring suction operation, the sucker should not disconnected

immediately after cleaning finishes.

A short delay (approx. 30 seconds) is required.

T5

B

D

CN