Uwatec MK 18 Assembly instructions

Other Uwatec Diving Instrument manuals

Uwatec

Uwatec Easydry Pro User manual

Uwatec

Uwatec DC-12 User manual

Uwatec

Uwatec Galileo 2 TEK User manual

Uwatec

Uwatec SMART TEC User manual

Uwatec

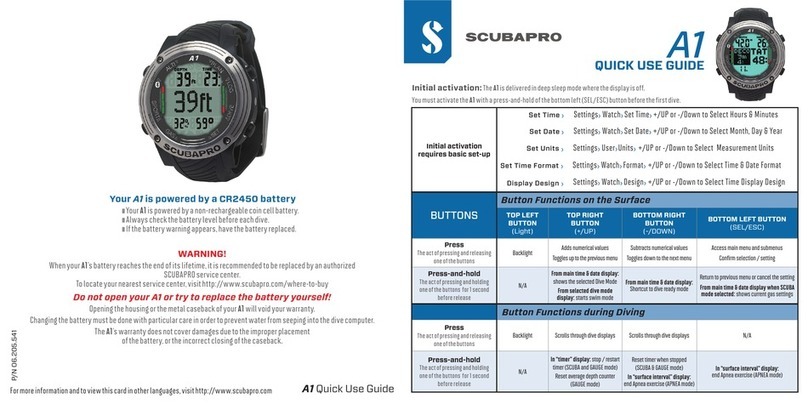

Uwatec Aladin A1 Operating manual

Uwatec

Uwatec DC-12 User manual

Uwatec

Uwatec Smart 2 User manual

Uwatec

Uwatec MK 11 User manual

Uwatec

Uwatec Z1 User manual

Uwatec

Uwatec A2 Operating manual

Uwatec

Uwatec Nova 230 User manual

Uwatec

Uwatec Meridian User manual

Uwatec

Uwatec Galileo sol User manual

Uwatec

Uwatec X650 Assembly instructions

Uwatec

Uwatec Aladin PRIME User manual

Uwatec

Uwatec D420 User manual

Uwatec

Uwatec G2 Operating manual

Uwatec

Uwatec MK 25 Assembly instructions

Uwatec

Uwatec R390 User manual

Uwatec

Uwatec PDIS User manual