V-TAC ESS Series User manual

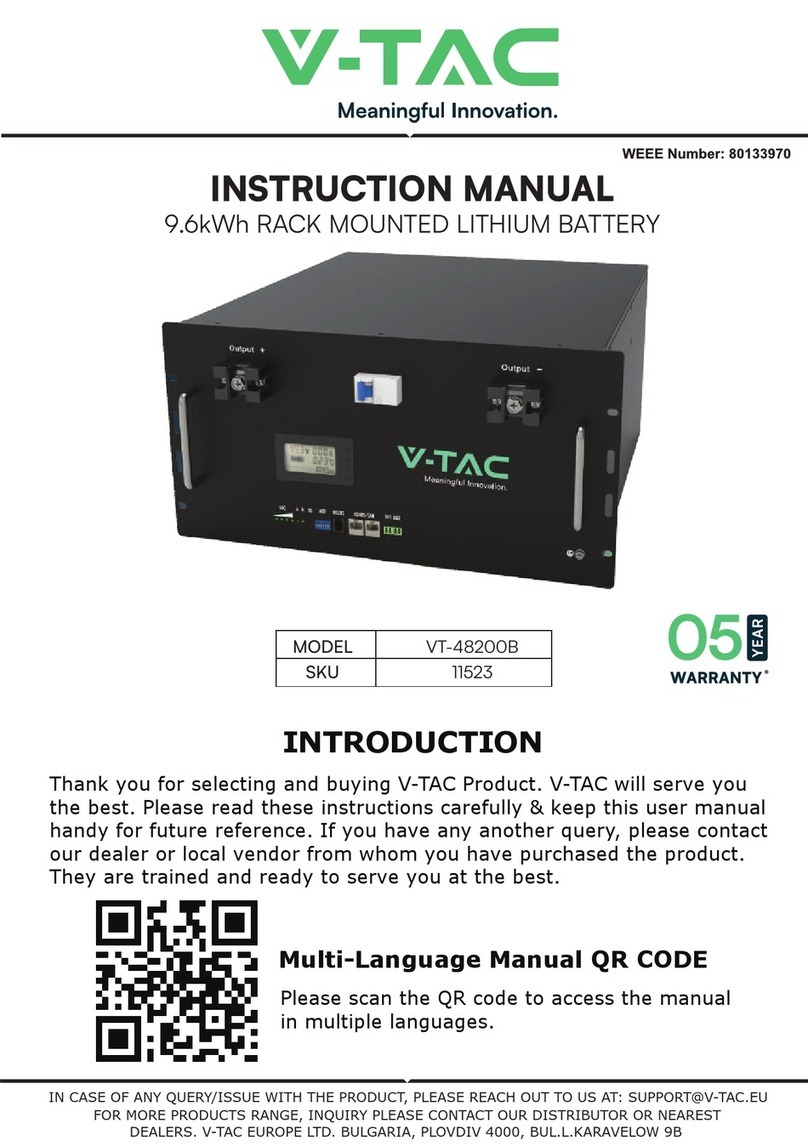

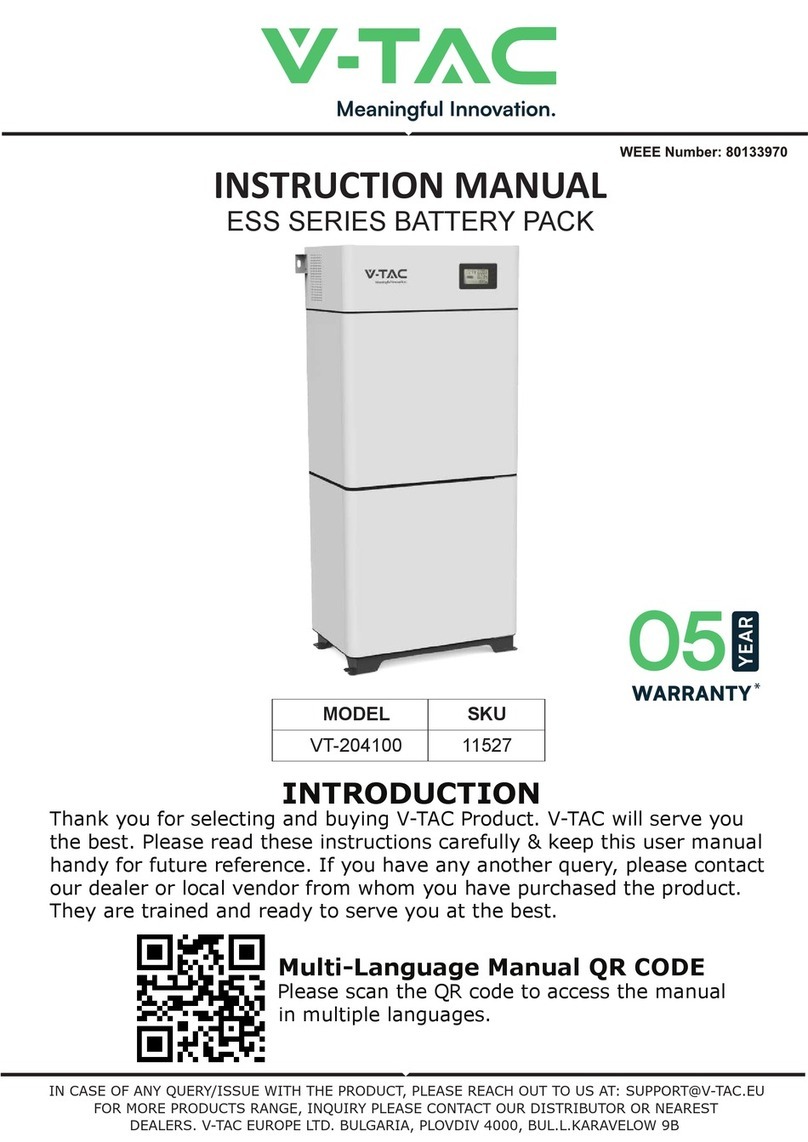

INSTRUCTION MANUAL

ESS SERIES BATTERY PACK

IN CASE OF ANY QUERY/ISSUE WITH THE PRODUCT, PLEASE REACH OUT TO US AT: SUPPORT@V-TAC.EU

FOR MORE PRODUCTS RANGE, INQUIRY PLEASE CONTACT OUR DISTRIBUTOR OR NEAREST

DEALERS. V-TAC EUROPE LTD. BULGARIA, PLOVDIV 4000, BUL.L.KARAVELOW 9B

Thank you for selecting and buying V-TAC Product. V-TAC will serve you

the best. Please read these instructions carefully & keep this user manual

handy for future reference. If you have any another query, please contact

our dealer or local vendor from whom you have purchased the product.

They are trained and ready to serve you at the best.

INTRODUCTION

Multi-Language Manual QR CODE

Please scan the QR code to access the manual

in multiple languages.

About This Document

Intended Audience

This document is intended for:

Hardware installation engineers

Technical support engineers

Maintenance engineers

Users

Symbol Conventions

The symbols that may be found in this document are defined as follows.

Symbol Definition Remarks

Danger Indicates a hazard with a high level of risk which, if not avoided, will

result in death or serious injury.

Warning Indicates a hazard with a medium level of risk which, if not avoided,

could result in death or serious injury.

Attention Indicates a hazard with a low level of risk which, if not avoided,

could result in minor or moderate injury.

Note

Supplements the important information in the main text.

NOTE is used to address information not related to personal injury,

equipment damage, and environmental deterioration.

2 Overview

2.1 Product Application

RESS is a next-generation product developed by V-TAC, which is used in residential energy storage solut

ions. This battery system has a capacity of 19.2 kWh or 20.48 kWh.

RESS integrates the high-performance BMS. To extend battery life, it has multiple protection functions

such as system over-charge, system over-discharge, cell over-voltage, cell under-voltage, charging over-

current, discharging over-current, and insulation fault. It also has RS485, CAN, and dry contact

communication, allowing for remote monitoring.

2.2 Product Composition

The RESS consists of one battery cabinet (two battery boxes and one chassis base inside), one high-

voltage box, and four battery modules.

The composition of the RESS is shown as follows:

Figure 1. RESS composition

(1) High-voltage box (2) Battery module (3) Battery cabinet

6

3 Components Introduction

3.1 Battery Cabinet

The appearance of the battery cabinet is shown as follows.

Figure 2. Battery cabinet appearance

The battery cabinet dimensions are shown as follows:

Figure 3. Battery cabinet dimensions (unit: mm)

7

3.2 Battery System

The battery system specifications are as follows.

Table 1. Battery system specifications

No. Items Parameter Remark

1 Rated voltage

VEH192100C: 192 V

VEH204100C: 204.8 V

2 Rated capacity 100 Ah

3 Rated energy

VEH192100C: 19.2 kWh

VEH204100C: 20.48 kWh

4 System efficiency 92% Watt-hour efficiency

5 Communication type CAN、RS485、DO/DI

6 Equalization Negative equalization ≤300 mA

7 Operation voltage range

VEH192100C: 168 V-204 V

VEH204100C: 179.2 V-217.6 V

8 Self-discharge ≤3% per month

9Max continuous charge

current 100 A

10 Max continuous discharge

current 100 A

11 Total voltage sampling 0 V-600 V ±(0.5%FS+0.1%RD)

12 Total current sampling 1 A-200 A

13 Temperature sampling NTC (-20℃~125℃) ±2℃

14 Insulation sampling 0~5MΩ

15 SOC estimate accuracy ≤8%

16 Charge ambient temperature 0℃-45℃Optimum ambient

temperature: 15℃-

35℃

17 Discharge ambient

temperature -10℃-45℃

18 Storage temperature 0℃-40℃

Copyright © Vestwoods Technology Co., Ltd. 8

No. Items Parameter Remark

19 Humidity 5%-95% RH, no condense

20 Protection

System over-voltage and system under-voltage, cell

over-voltage and cell under voltage, charging over-

current and discharging over-current, charging high

temperature and charging low temperature,

discharging high temperature and discharging low

temperature, short circuit protection, insulation

faulty protection

21 Dimensions (W×H×D) 640 mm×1280 mm×350 mm

22 Weight

VEH192100C: Approx. 230kg

VEH204100C: Approx. 238kg

3.2.1 Lithium-ion Cell

The lithium iron phosphate cell selected in the scheme is a special energy-type lithium battery product.

This series of lithium iron phosphate cells have high specific energy, longer cycle life, low cost, capable of

high current charge and discharge, high-temperature tolerance, high energy density, no battery memory

effect, safety, and pollution-free features.

3.2.1.1 Appearance

Lithium-ion cell's three views are shown as follows.

Figure 4. Lithium-ion cell three views (unit: mm)

9

3.2.1.2 Technical Specifications

Lithium-ion cell main technical specifications are shown as follows.

Table 2. Lithium-ion cell main technical specifications

No. Items Specification

1 Battery type Lithium iron phosphate

2 Model LF100MA

3 Rated voltage 3.2 V

4 Rated capacity 100 Ah

5 Rated energy 0.32 kWh

6 Max continuous charge current 100 A

7 Max continuous discharge current 100 A

8 Charging cut-off voltage 3.65 V

9 Discharging cut-off voltage 2.50 V

10 Operating charging temperature 0℃-55℃

11 Operating discharging temperature -20℃-45℃

12 Storage temperature

-20-45℃(less than 1 month);

0-35℃(less than 12 months);

13 Operating humidity 5%-95% RH

14 Cycle life ≥3500 cycle@ 25℃80%DOD

15 Size (Width*High*Depth) 160 mm×115.7 mm×50.1 mm

16 Weight About 1.92 kg

3.2.2 Battery Module

15 or 16 lithium cells are packed in the battery module, assembled in a combination of 1 parallel, 15, or

16 series.

The battery module is integrated with BMU to collect voltage and temperature and monitor the battery

module's status at all times.

10

3.2.2.1 Appearance

The battery module appearance is shown as follows.

Figure 5. Battery module appearance

The battery module's three views are shown as follows.

Figure 6. Battery module three views (unit: mm)

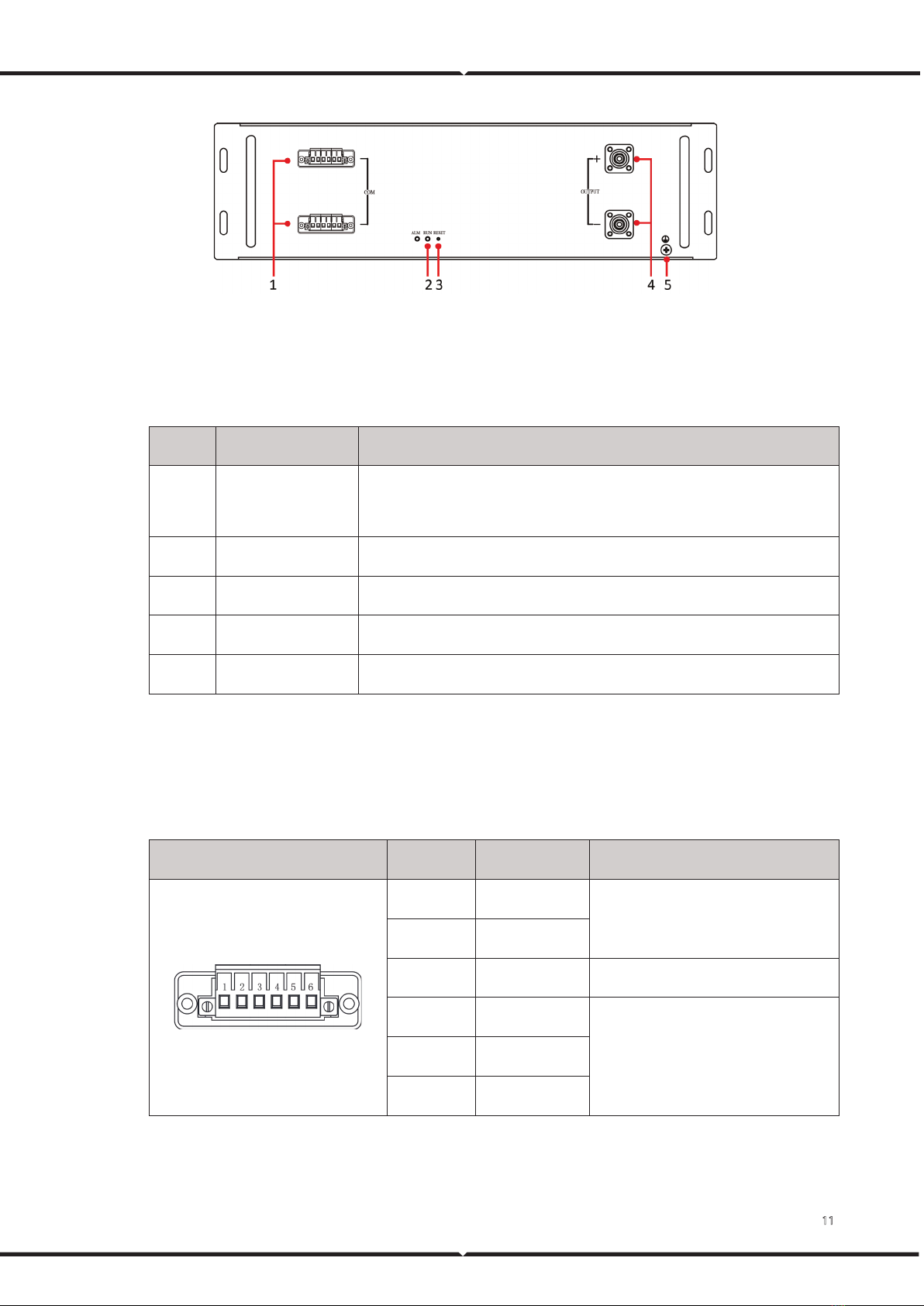

3.2.2.2 Operation Panel

The battery module operation panel is shown as follows.

11

Figure 7. Battery module operation panel

The definition of the battery module operation panel is shown as follows.

Table 3. Operation panel definition

No. Items Remark

1 Communication port

Communicate with other battery modules;

Communicate with high-voltage box.

2 Running indicator Indicate battery module running status.

3 Reset switch Reset BMU.

4 Output connectors Battery module output connectors.

5 Ground Ground.

3.2.2.3 PIN Definition

The PIN definition of a communication port is shown as follows.

Table 4. Communication port PIN definition

Location schematic diagram Location Definition Remark

1 24 V+

BMU power supply

2 24 V-

3 - -

4 CAN0H

Communication between BMU and BCU.

5 CAN0L

6 CAN0S

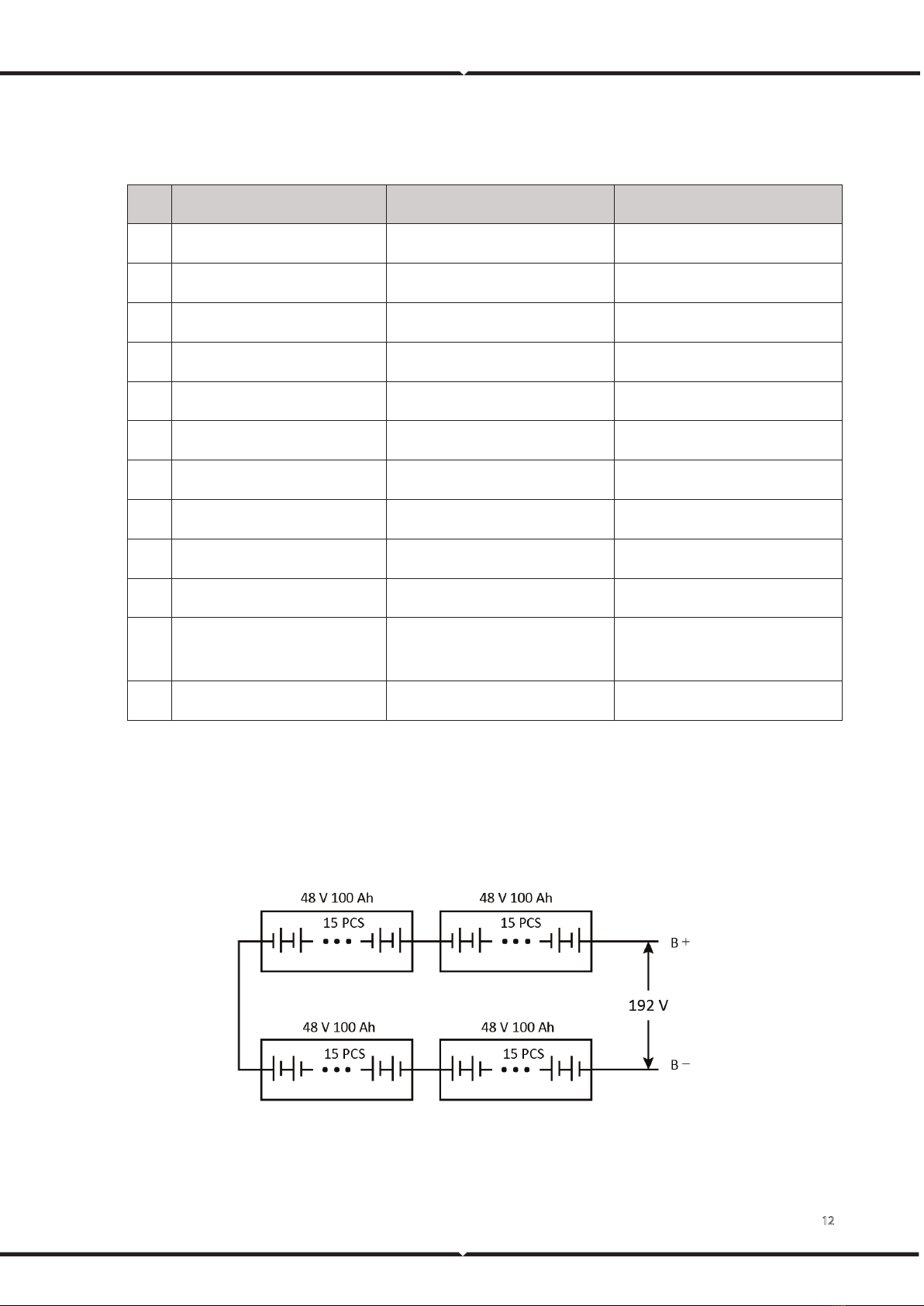

3.2.2.4 Technical Specifications

Copyright © Vestwoods Technology Co., Ltd. 12

The battery module's main technical specifications are shown as follows.

Table 5. Battery module main technical specifications

No. Items VT48100E-H1 VT48100E-H2

1 Model VT48100E-H1 VT48100E-H2

2 The number of cells 15 16

3 Cells in series and parallel 1P15S 1P16S

4 Model 48 V 51.2 V

5 Rated voltage 100 Ah 100 Ah

6 Rated capacity 4.80 kWh 5.12 kWh

7 Charging cut-off voltage 54.0 V 57.6 V

8 Discharging cut-off voltage 37.5 V 40.0 V

9 Max continuous charge current 100 A 100 A

10 Max continuous discharge current 100 A 100 A

11 Size (Width*High*Depth) 482 mm×130 mm×455 mm (With

the handle)

482 mm×130 mm×455 mm (With

the handle)

12 Weight About 39 kg About 41 kg

3.2.3 Battery Cluster

The battery cluster is composed of 4 battery modules. The schematic diagrams of battery clusters are

shown as follows.

Figure 8. VEH192100C battery cluster composition diagram

Other manuals for ESS Series

4

This manual suits for next models

2

Table of contents

Other V-TAC Batteries Pack manuals

Popular Batteries Pack manuals by other brands

Inventus Power

Inventus Power PROTRXion S-12V100-TRX-HD user manual

Clas Ohlson

Clas Ohlson PW-290A quick start guide

EINHELL

EINHELL MULTI-Ah Power X-Change Plus Original operating instructions

Samsung

Samsung EB-U3300 quick start guide

ECTIVE

ECTIVE LC Series instruction manual

Narada

Narada 12REXC70 Operation manual