92077r14

V200 POSITIONER

www.vacaccessories.com

3

1 INTRODUCTION

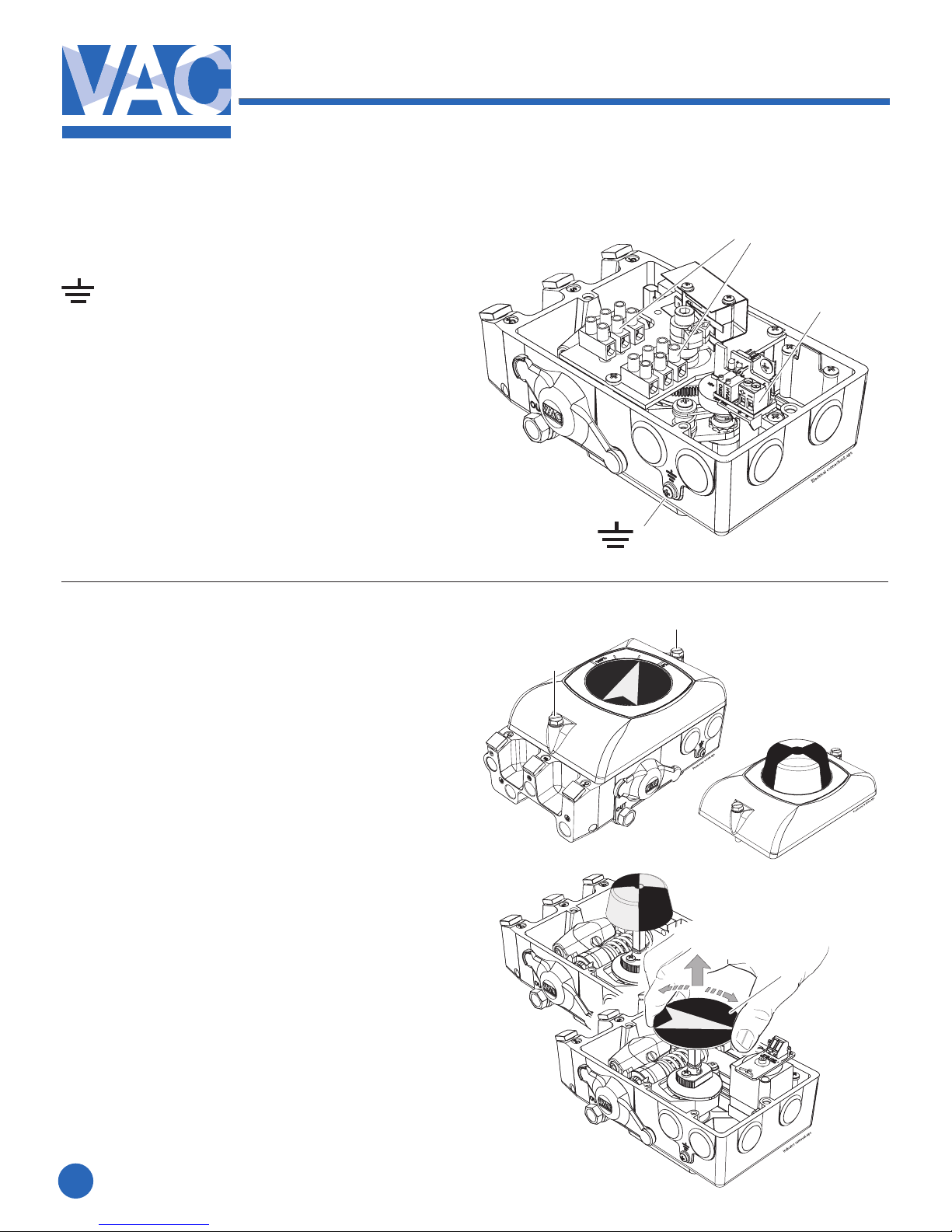

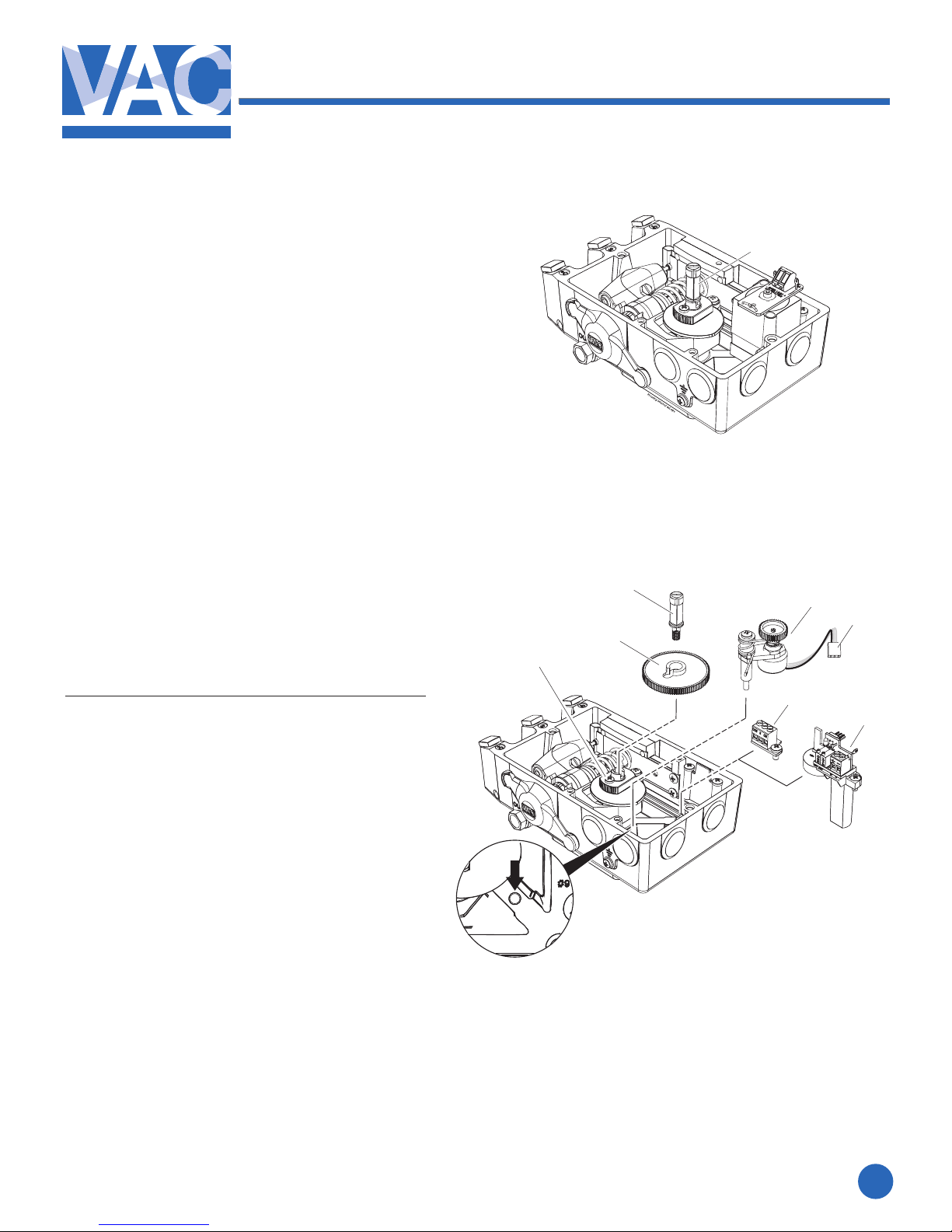

1.1 Principle of operation

The V200 feedback options allows for accurate

positionfeedback,whereon-o(open/closed)

indication(switches)orcontinuous4-20mA

transmission(orsimplepotentiometer)isrequired.

Anyfeedbackmodulecanbefactoryoreldinstalled

inside the V200 positioner housing with no special

parts or mounting brackets. This creates a very

compact and simple package that is completely

sealed.

The various feedback options are connected to the

positionermaindriveshaft(1)whichisconnectedto

the actuator shaft via the positioner spindle, assisting

inamoredirectandaccurateactuator/valvemonitoring.

A position change moves the V200 spindle and switch

cam(2)foron-o(oropen/closed)indication.

The4-20mApositiontransmittermkII(3)respondsto

changesproportionallyintheactuator/valvepackage.

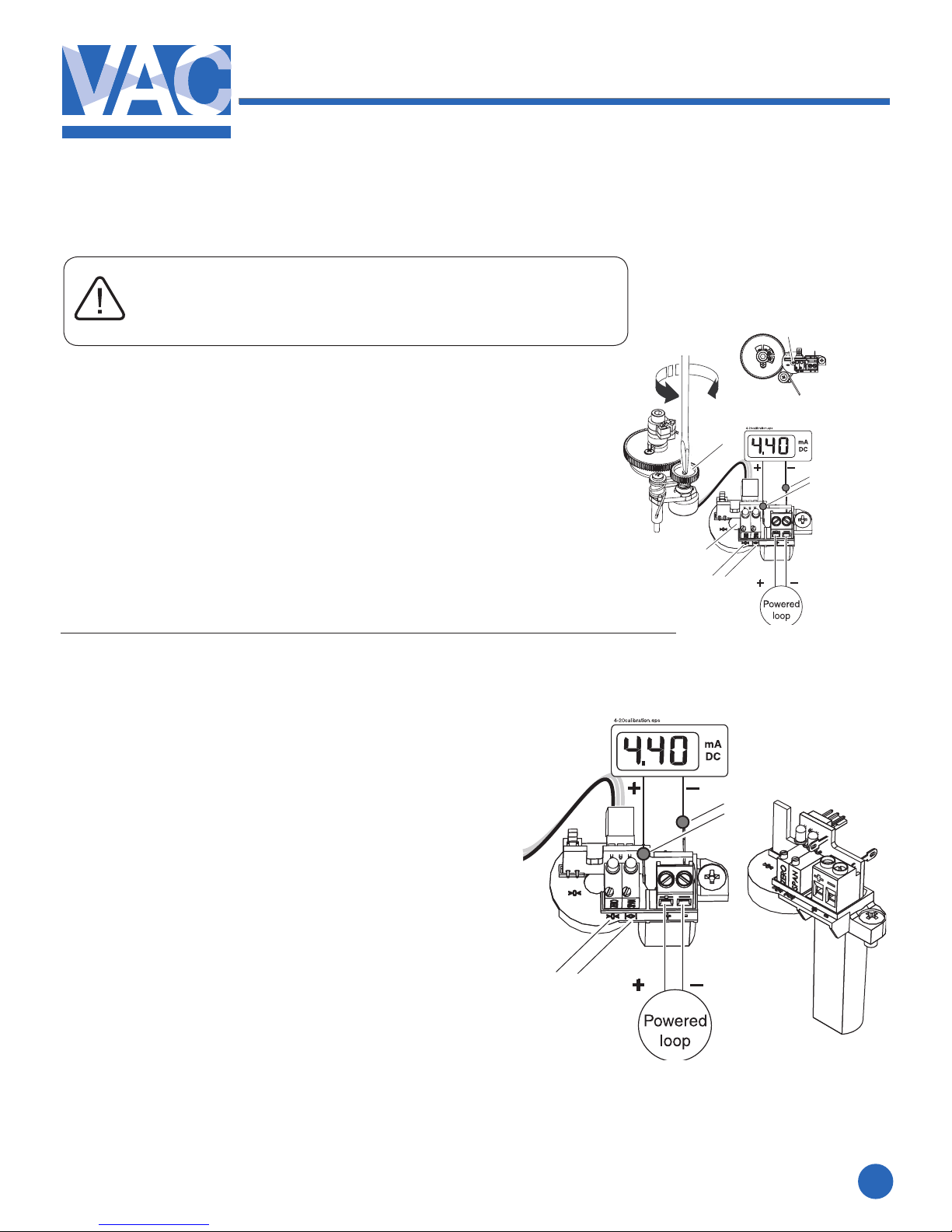

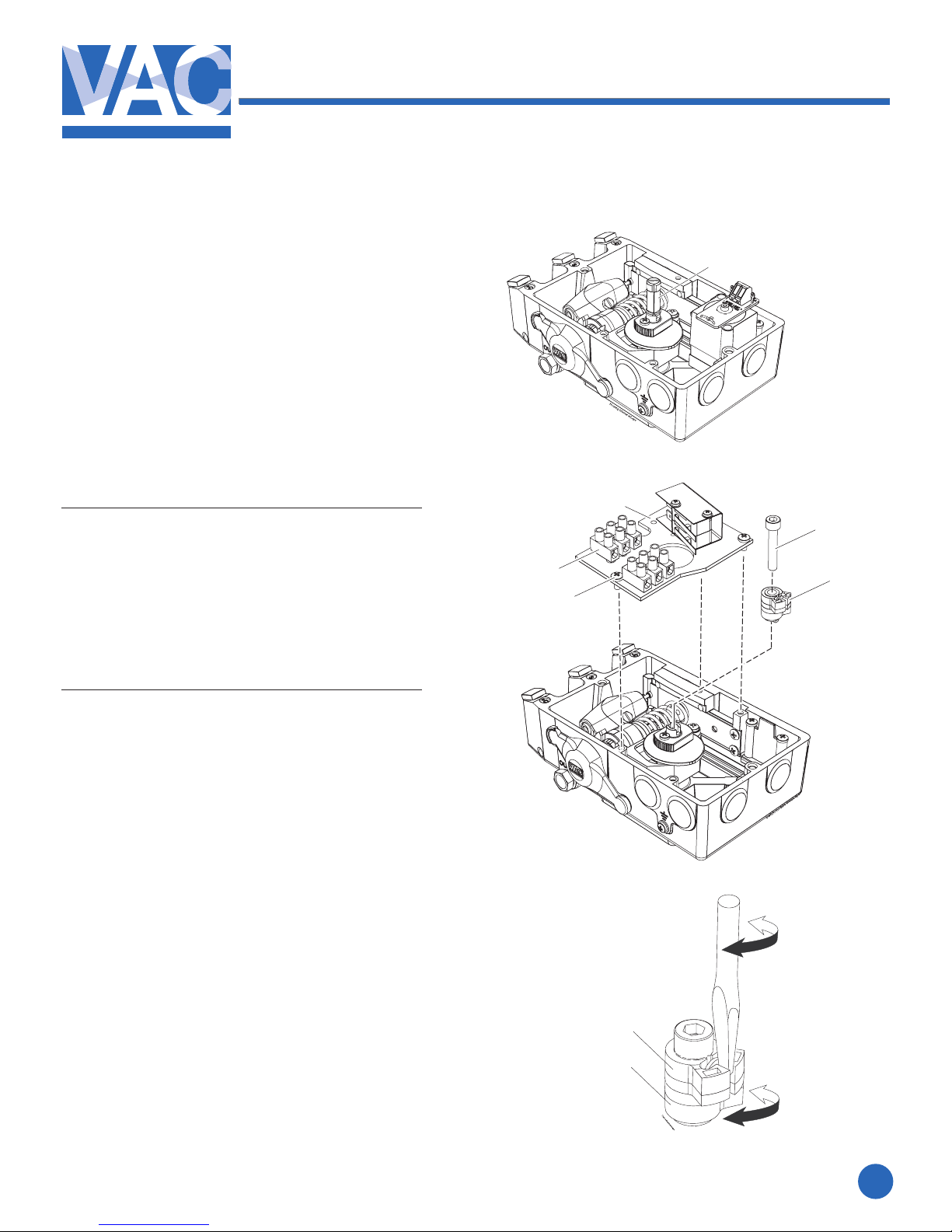

It is recommended that the V200 positioner be

calibrated before installing feedback options.

CAUTION:

Beware of moving parts

when positioner is operated!

1.3 Safety instruction

CAUTION: Beware of parts with live voltage!

A voltage, which is normally not dangerous, is supplied to the positioner. Avoid touch-

ing live parts and bare wires as well as short circuiting live parts and the housing.

1.2 Product identication

TheV200identicationtags,Serialnumbertag(1),product-

modeltag(2)andfeedbackoptiontag(3),areplacedasshown.

The product model tag contains information on control signal,

maximum working pressure and temperature ranges.

Other information can be shown depending on the model.

Not for use in Hazardous locations.

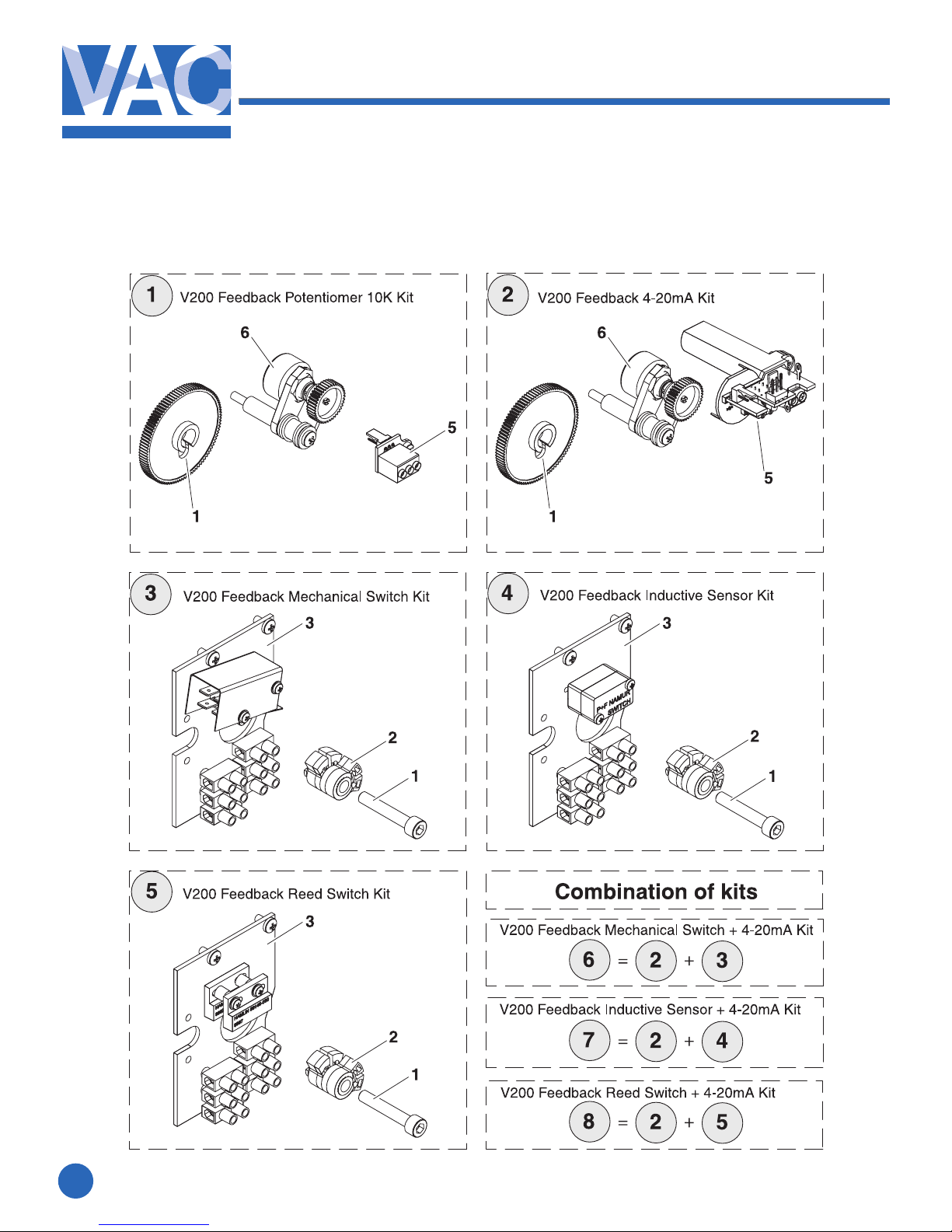

Feedback options described in this manual

are for for General purpose only.

1

3

2