important - please read

general installation

27

maintenance

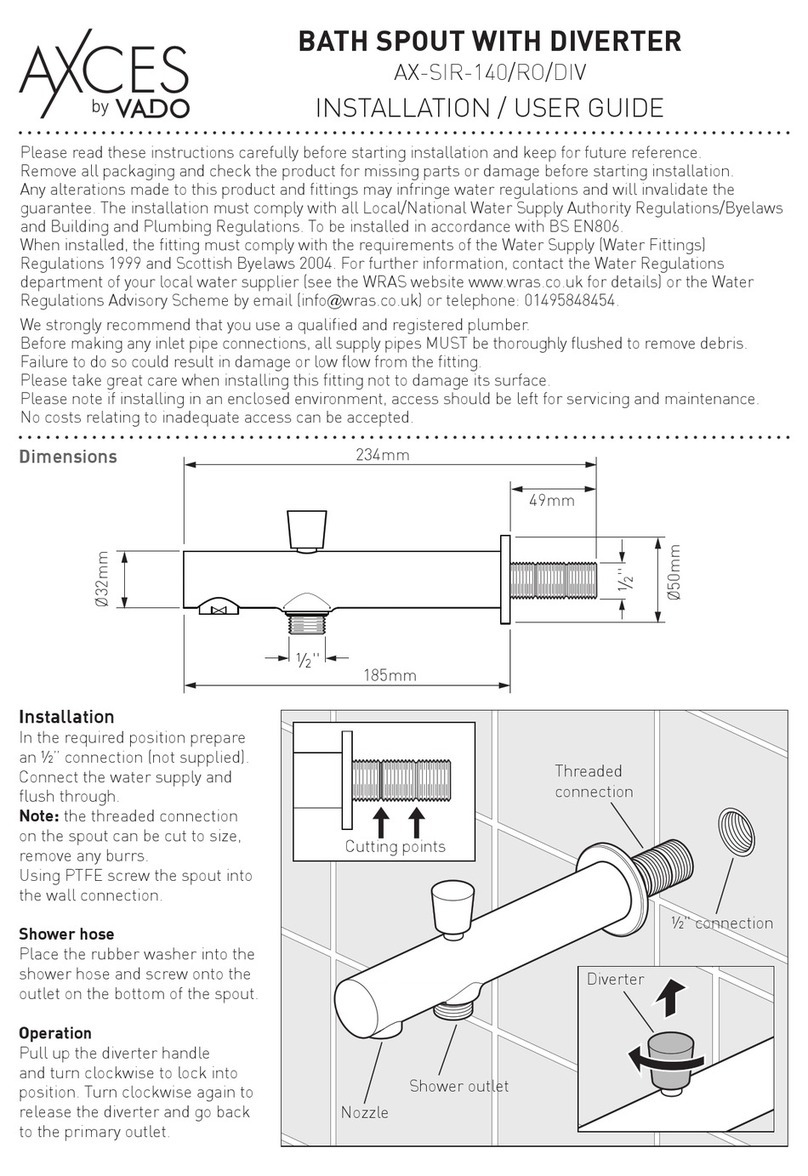

Please read these instructions carefully before starting installation and keep for future

reference.

Remove all packaging and check the product for missing parts or damage before

starting installation.

Any alterations made to this product and ttings may infringe water regulations and

will invalidate the guarantee.

The installation must comply with all Local/National Water Supply Authority

Regulations/Byelaws and Building and Plumbing (UK:BS6700) Regulations.

We strongly recommend that you use a qualied and registered plumber.

Thermostatic Valves

This mixer valve is suitable for any water system, provided minimum water pressure

is met. Where instantaneous heaters are used, the ow of hot water sucient to start

and go on burning must reach the minimum ow required – as specied by the heater

manufacturer.

These ttings are mixing devices and therefore water supplies must be reasonably

balanced.

Where connections are made to the mains cold water supply, WRC approved single

check valves must be tted to both hot and cold inlets. This is a stated requirement of

Water Supply (Water Fittings) Regulations 1999 Schedule 2, Section 6 G15.13.2

Before making any inlet pipe connections, all supply pipes MUST be thoroughly

ushed to remove debris. Failure to do so could result in damage or low ow from the

mixer unit. Water Supply (Water Fittings) Regulations 1999 Schedule 2 Section 4 G13.1

The tting of isolating valves to the inlet feeds is advised for ease of maintenance.

Please take great care when installing this mixer not to damage its surface.

Operating pressures (on hot and cold line) should be kept as balanced as possible in

order to assure optimum eciency.

Note: When pressure is higher than 5 bar a pressure reducer is required to be tted

before the valve.

Please note if installing in an enclosed environment, access should be left for servicing

and maintenance. No costs relating to inadequate access can be accepted.

This thermostatic valve is tted with a double ltering facility. Filters are tted on the

water inlets and on the thermostatic cartridge.

Depending on the water quality, lters may become dirty, causing reduced ow and

inecient working of the valve.

To clean the lters, you must rst remove the cartridge from the housing.

Removing the Cartridge

1. Shut o the water supply to both inlets at the isolating valves.

2. Remove the handle – pull it out.

3. Remove the small screw from the valve ring and pull o, taking care not to loose the

temperature stop button and spring. Pull o the stop ring.

4. Unscrew and remove the thermostatic cartridge.

5. Clean the lters by rinsing them in water to remove the dirt and soaking them in

vinegar or descaling agent.

6. Before reassembling the cartridge, clean its housing with a wet cloth and grease the

‘O’ rings on the cartridge, reassemble the cartridge.

7. Push on the stop ring with the notch at the 12 o’clock position, followed by the valve

ring with the temperature stop button at 6 o’clock and secure using the retaining

screw do not over tighten. Push on the control handle body and tighten the allen bolt,

screw on the handle.

8. Make sure everything is tight and secure and turn on the water supply at the

isolating valves.

9. Now check the water temperature to ensure you are happy with it.

ZOO 147T Pag.indd 2 11/2/10 11:29:21