VDH PROBA 5 Compact User manual

Other VDH Thermostat manuals

VDH

VDH ALFA 59 User manual

VDH

VDH ALFA(NET) 51 PI User manual

VDH

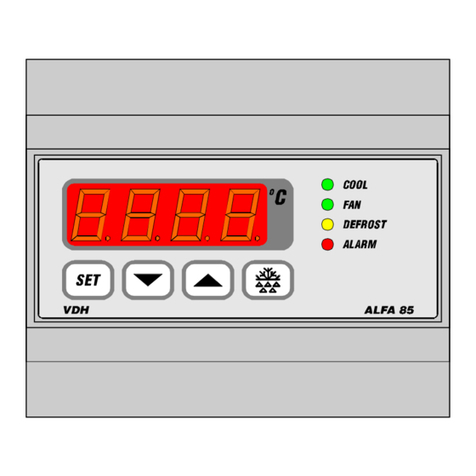

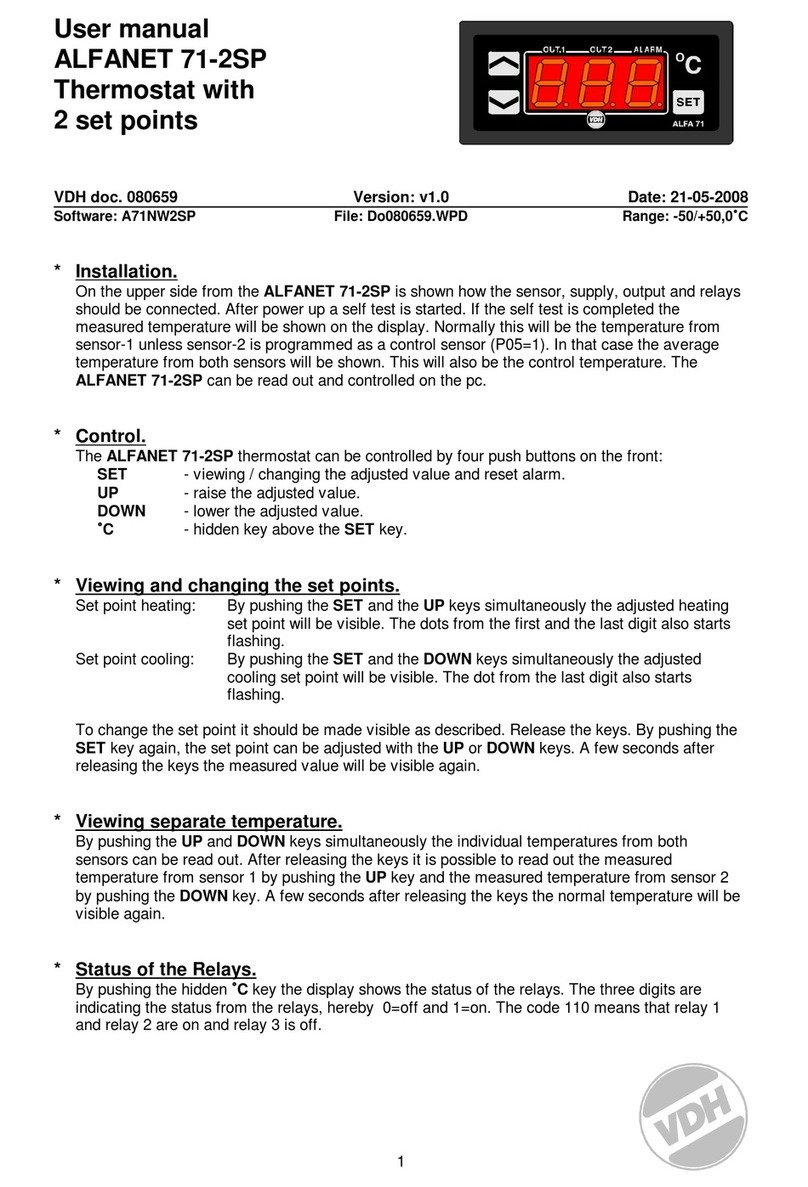

VDH ALFANET 71-2SP User manual

VDH

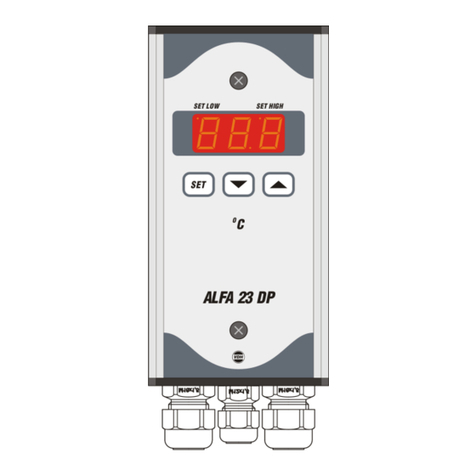

VDH ALFA 35 DP User manual

VDH

VDH ALFANET 55 RTDF User manual

VDH

VDH ALFA 71 User manual

VDH

VDH ALFA(NET) 71 PI User manual

VDH

VDH ALFANET 71 User manual

VDH

VDH ALFA 31 User manual

VDH

VDH ALFA 71 S PI User manual

Popular Thermostat manuals by other brands

Charmeg

Charmeg MP-R user manual

dixell

dixell WING XW40LS Installing and operating instructions

Network Thermostat

Network Thermostat NetX X7C-WIFI Installation and programming manual

Radio Thermostat

Radio Thermostat CT80 Operation guide

HAI

HAI Omnistat RC-120 installation manual

Lennox

Lennox iComfort E30 Installation and setup guide

Lux Products

Lux Products PSD011Ba Installation and operating instructions

Computherm

Computherm Q20 operating instructions

Heatmiser

Heatmiser neoStat user manual

Mars

Mars HEAT CONTROLLER IR Wireless Thermostat user manual

LUX

LUX LP0511D user manual

Saswell

Saswell SAS920XWHB-7-S-RF User manual and warranty card