3Product description

3.1Configuration

The VEGAPULS 62 radar sensor is available in two electronics

versions:

lStandard electronics type PS60K

lElectronics with increased sensitivity type PS60S

The respective version can be determined by means of the

type label on the electronics.

The electronics version influences the CE conformity,the

functional safety (SIL), the factory setting for the product

selection and vessel,form,the accuracy,the voltage supply as

well as the approvals of VEGAPULS 62.The differences are

specified in this operating instructions manual in the respective

paragraphs.

The scope of delivery encompasses:

lVEGAPULS 62 radar sensor

ldocumentation

-this operating instructions manual

-Supplementary instructions manual "Safety Manual -

Functional safety acc.to IEC 61508 (SIL)"2)

-Operating instructions manual "Indicating and adjust-

ment module PLICSCOM"(optional)

-Supplementary instructions manual "Heating for indi-

cating and adjustment module PLICSCOM"(optional)

-Supplementary instructions manual "Plug connector for

continuously measuring sensors"(optional)

-Ex-specific"Safety instructions"(with Ex versions)

-if necessary,further certificates

VEGAPULS 62 consists of the following components:

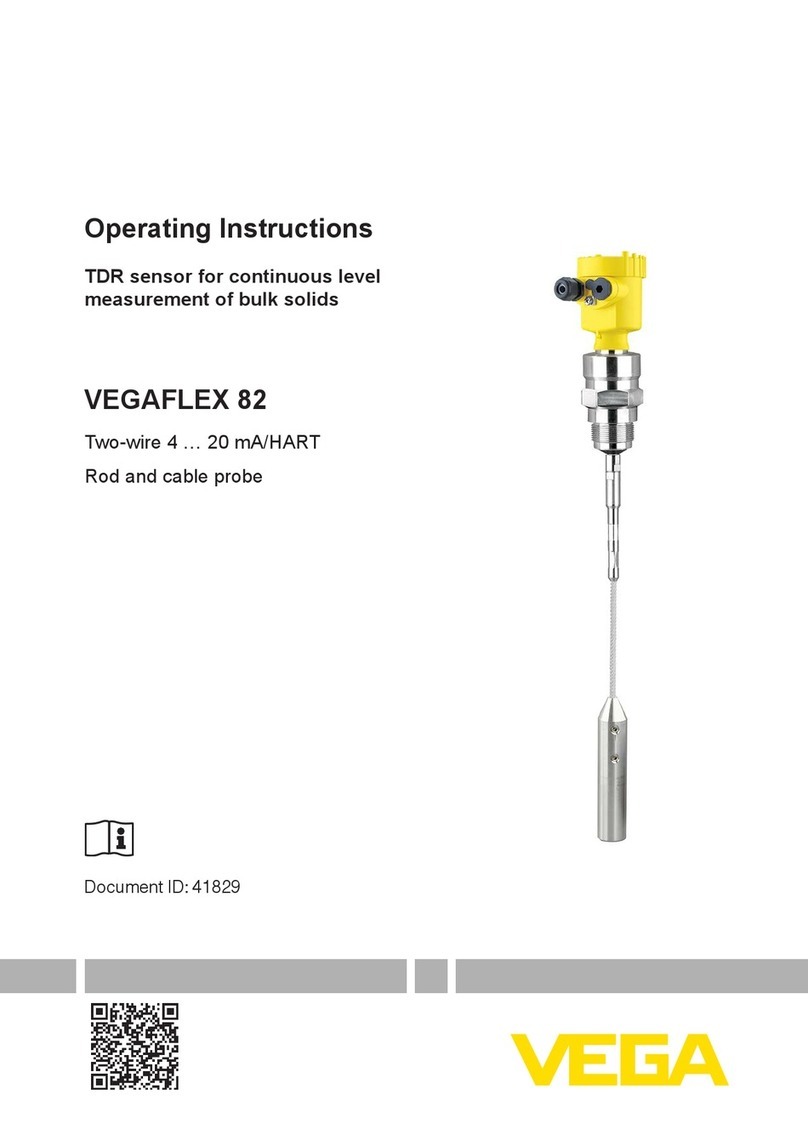

lHorn or parabolic antenna

lprocess fitting (depending on the version flange or thread)

loptionally available with purging air connection,reflux valve

lHousing with electronics,optionally available with plug

connector,optionally available with connection cable

lHousing cover,optionally available with indicating and

adjustment module PLICSCOM

The components are available in different versions.

2)Not with electronics version with increased sensitivity

Versions

Scope of delivery

Components

10 VEGAPULS 62 -4... 20 mA/HART

Product description

28435-EN-060317