Contents

1About this document

1.1Function.................................. 4

1.2Target group .............................. 4

1.3Symbolism used............................ 4

2For your safety

2.1Authorised personnel ........................ 5

2.2Appropriate use ............................ 5

2.3Warning about misuse ....................... 5

2.4General safety instructions . . . . . . . . . . . . . . . . . . . . 5

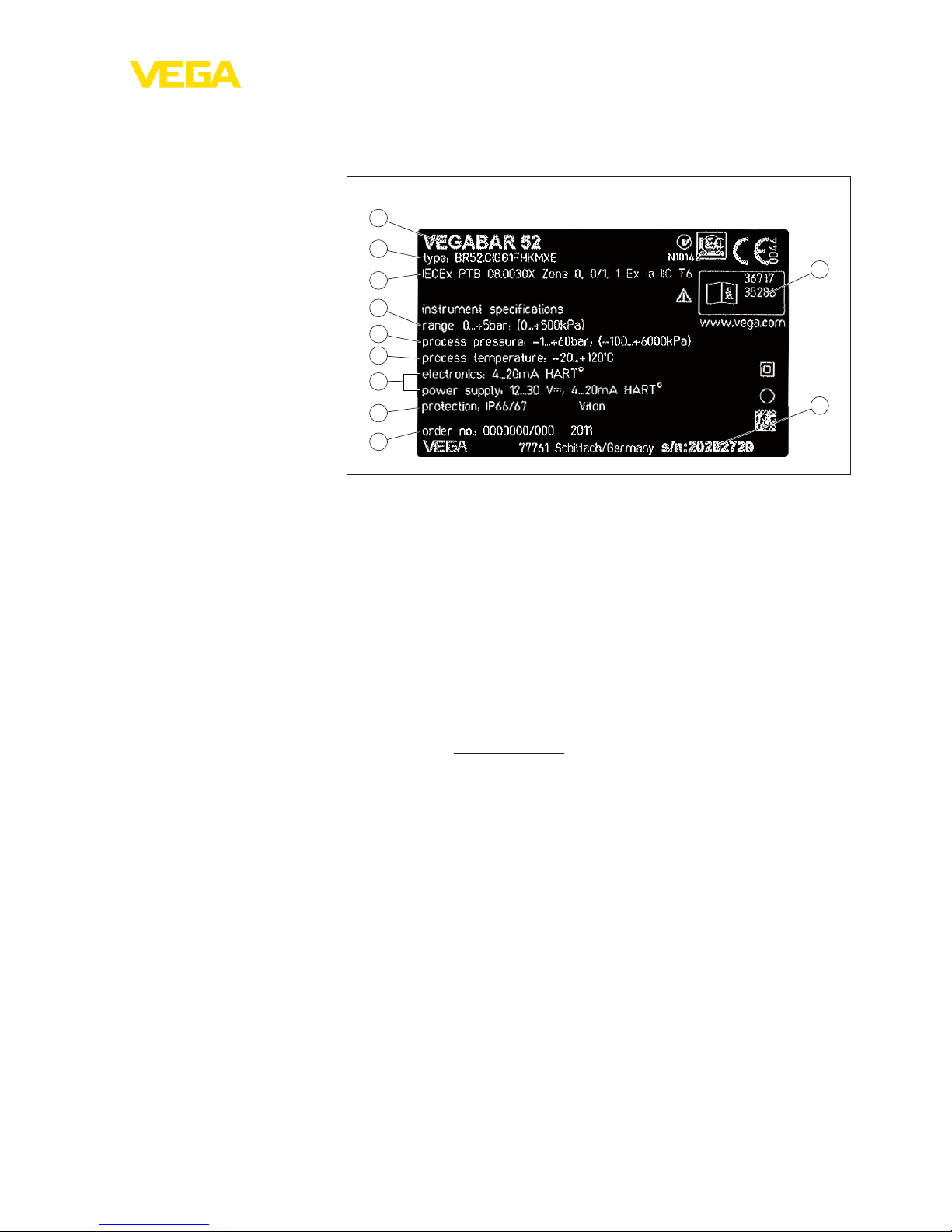

2.5Safety label on the instrument . . . . . . . . . . . . . . . . . . 6

2.6CE conformity ............................. 6

2.7Measuring range -permissible process pressure . . . . 6

2.8Fulfillment of NAMUR recommendations . . . . . . . . . . 6

2.9Safety instructions for Ex areas . . . . . . . . . . . . . . . . . 6

2.10 Environmental instructions..................... 6

3Product description

3.1Structure ................................. 7

3.2Principle of operation ........................ 9

3.3Operation................................. 10

3.4Packaging,transport and storage ............... 11

3.5Accessories and replacement parts . . . . . . . . . . . . . . 11

4Mounting

4.1General instructions ......................... 13

4.2Mounting preparations ....................... 14

4.3Mounting steps with straining clamp . . . . . . . . . . . . . 16

4.4Mounting steps with screwed connection . . . . . . . . . . 17

4.5Mounting steps with lock fitting . . . . . . . . . . . . . . . . . 18

4.6Mounting steps with housing and thread . . . . . . . . . . 19

4.7Mounting steps,external housing. . . . . . . . . . . . . . . . 20

5Connecting to power supply

5.1Preparing the connection ..................... 21

5.2Connection procedure........................ 22

5.3Wiring plan,single chamber housing . . . . . . . . . . . . . 24

5.4Wiring plan,double chamber housing . . . . . . . . . . . . 25

5.5Wiring plan,double chamber housing Ex d . . . . . . . . 27

5.6Wiring plan -version IP 66/IP 68,1bar . . . . . . . . . . . 29

5.7Wiring plan,external housing with version IP 68 . . . . . 29

5.8Switch-on phase............................ 32

6Set up with the indicating and adjustment module PLICSCOM

6.1Short description ........................... 33

6.2Insert indicating and adjustment module. . . . . . . . . . . 33

6.3Adjustment system .......................... 35

6.4Setup steps ............................... 36

2VEGABAR 66 •Foundation Fieldbus

Contents

36740-EN-120324