VEGA

FLEX 62 – 4 … 20 mA/HART®

5

2

7822-EN-030715

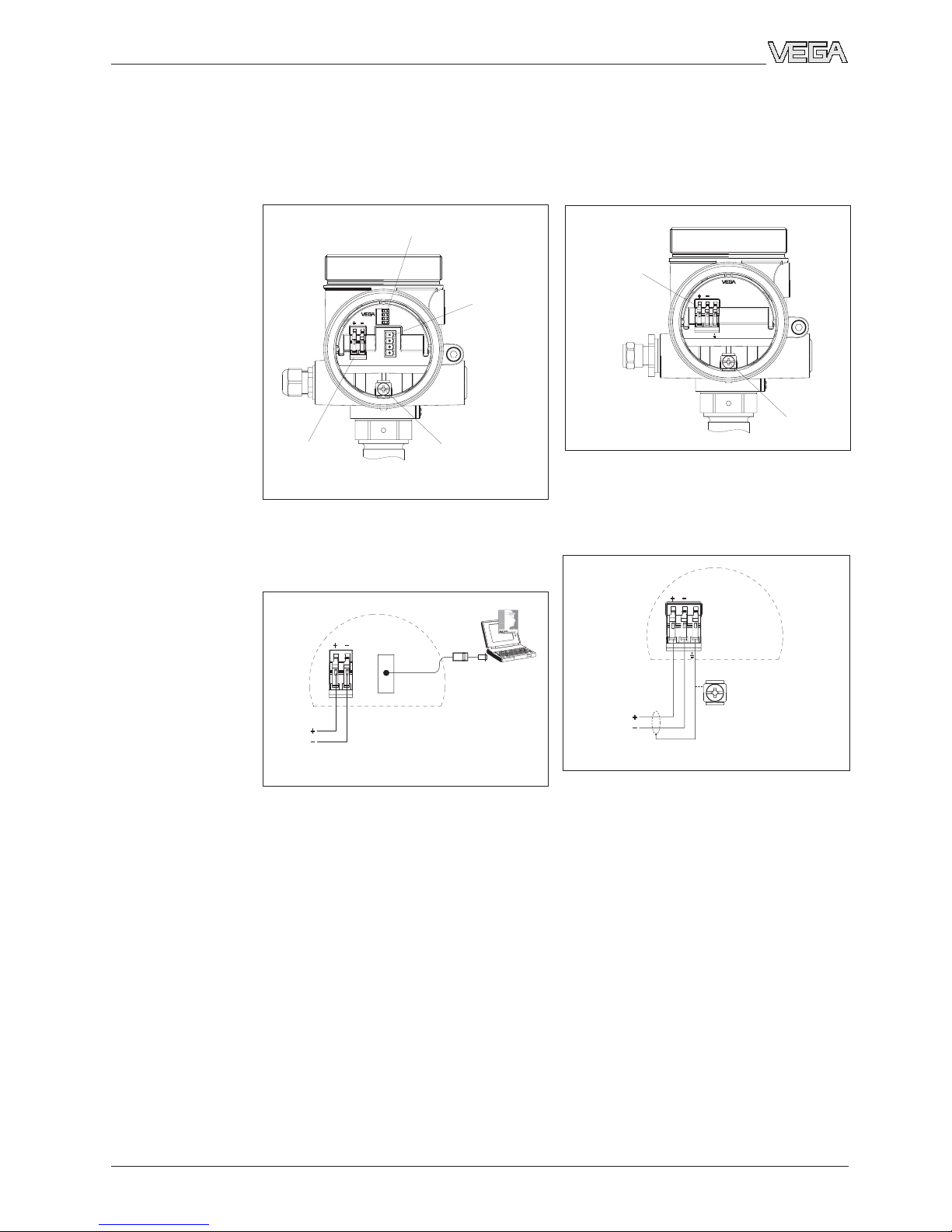

Connection to power supply

2 Connection to power supply

2.1 Preparing the connection

Take note of safety instructions for Ex

applications

In hazardous areas you should take

note of the appropriate regulations and

type approval certificates of the sen-

sors and power supply units. The sen-

sors must only be operated on intrinsically safe

circuits. The permissible electrical values are

stated in the certificate.

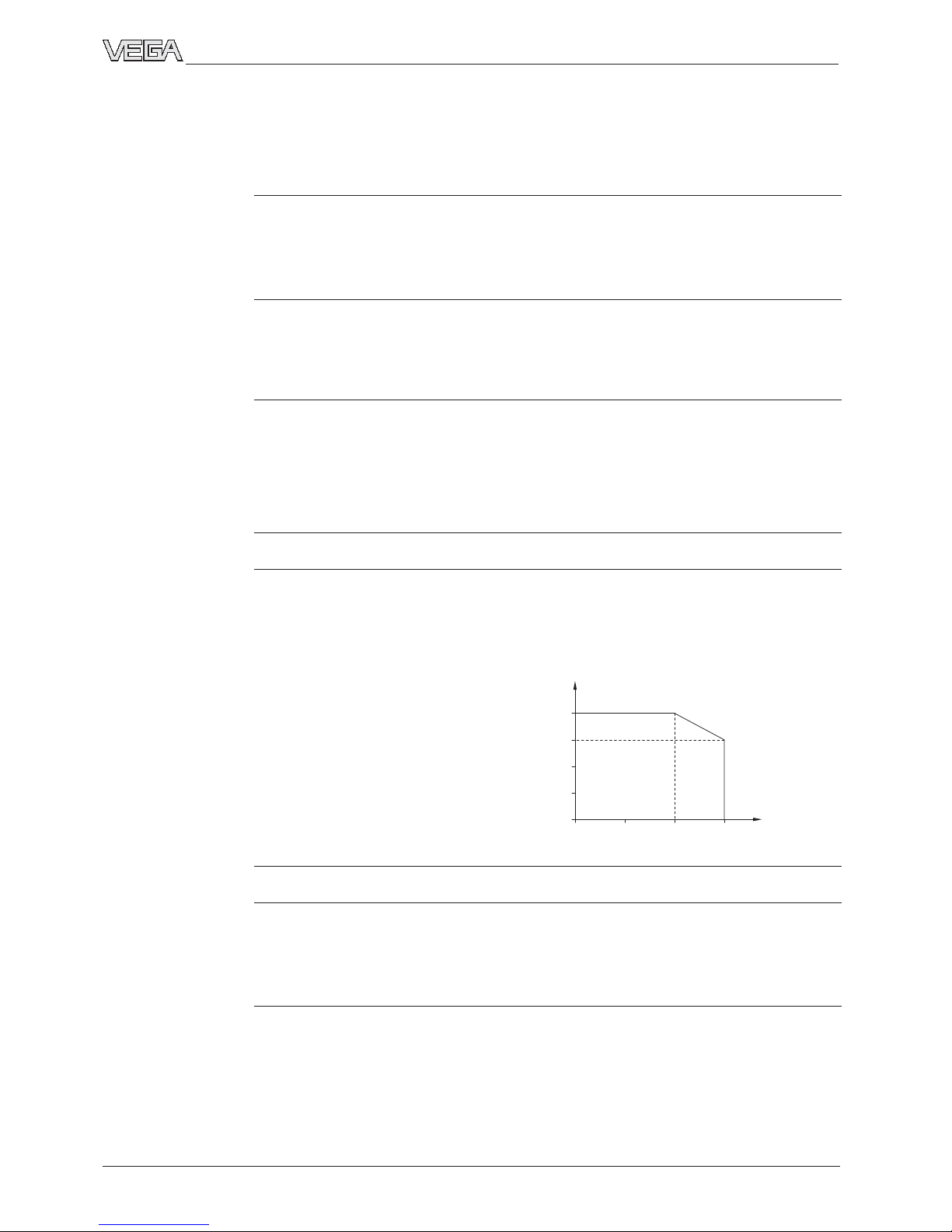

Select voltage supply

VEGAFLEX requires a supply voltage of

14 … 36 V DC. Power supply and current signal

are led via the same two-wire connection cable.

Provide a reliable separation between the exter-

nal energy source and the mains circuits acc. to

DIN VDE 0106 part 101. The VEGA power supply

units VEGATRENN 149AEx, VEGASTAB 690,

VEGADIS 371 as well as all VEGAMETs meet this

requirement. When using one of these instru-

ments, protection class II is ensured for

VEGAFLEX 62.

Bear in mind the following factors regarding

supply voltage:

• Reduction of the output voltage of the power

supply unit under nominal load

• Influence of additional instruments in the cir-

cuit (see load values in Technical data).

Anschlusskabel auswählenSelect connec-

tion cable

VEGAFLEX is connected with standard two-wire

cable. An outer diameter of 5 … 9 mm ensures

the seal effect of the cable entry.

If strong electromagnetic interference is ex-

pected, shielded cable is recommended. The

screen should be applied on both ends.

Select connection cable for Ex

applications

Take note of the corresponding installa-

tion regulations for Ex applications.