SI30 Solar Pump Inverter Manual

4

1.3 Cautions in Using

1. In application of this series solar pump inverter, you have to confirm all machine insulation to

prevent damage to the equipment. Moreover, when the motor working in tough environment, please

periodic inspect the electrical insulation to ensure the safety of the system work.

2. If the motor adapter is not consistent with solar pump inverter's rating current (The rating current

of the motor is far smaller than that of solar pump inverter), please adjust the protective value to ensure

safe running.

3. In occasions such as load raises, usually there is negative torque and solar pump inverter breaks

off for over-current or over-voltage. In this case, you should consider choosing the matching brake unit.

4. Solar pump inverter, in a certain output frequency range, can meet the mechanical resonance of

the load equipment. To avoid it, you can set up jumping frequency.

5. As output voltage of the inverter is pulse-wave type, if there is capacity which can improve power

factor or pressure-sensitive resistance which used for thunder-proof in the voltage output side, the solar

pump inverter will break off or its parts will be damaged, so it is necessary to dismantle them. Moreover, it

is proposed not install switch parts like air switch and contactor (if it is necessary to install switch on

output side, please make sure the output electricity of solar pump inverter is zero when the switch is

working).

6. At over 1,000 meters altitude, the inverter’s heat dissipation function worsened due to the thin air,

it is necessary to use less.

7. The inverter output voltage is pulse wave type. If using digital multi-meter measurement, deviation

of the reading will be great. And the deviation is different by using different type of digital multi-meter.

Under normal circumstances, while RMS 380V, digital multi-meter reading is around 450V.

8. Solar panel can be connected in series or parallel. For rated voltage 380V controller, we suggest

solar panel open circuit voltage should be between 620V~750V.

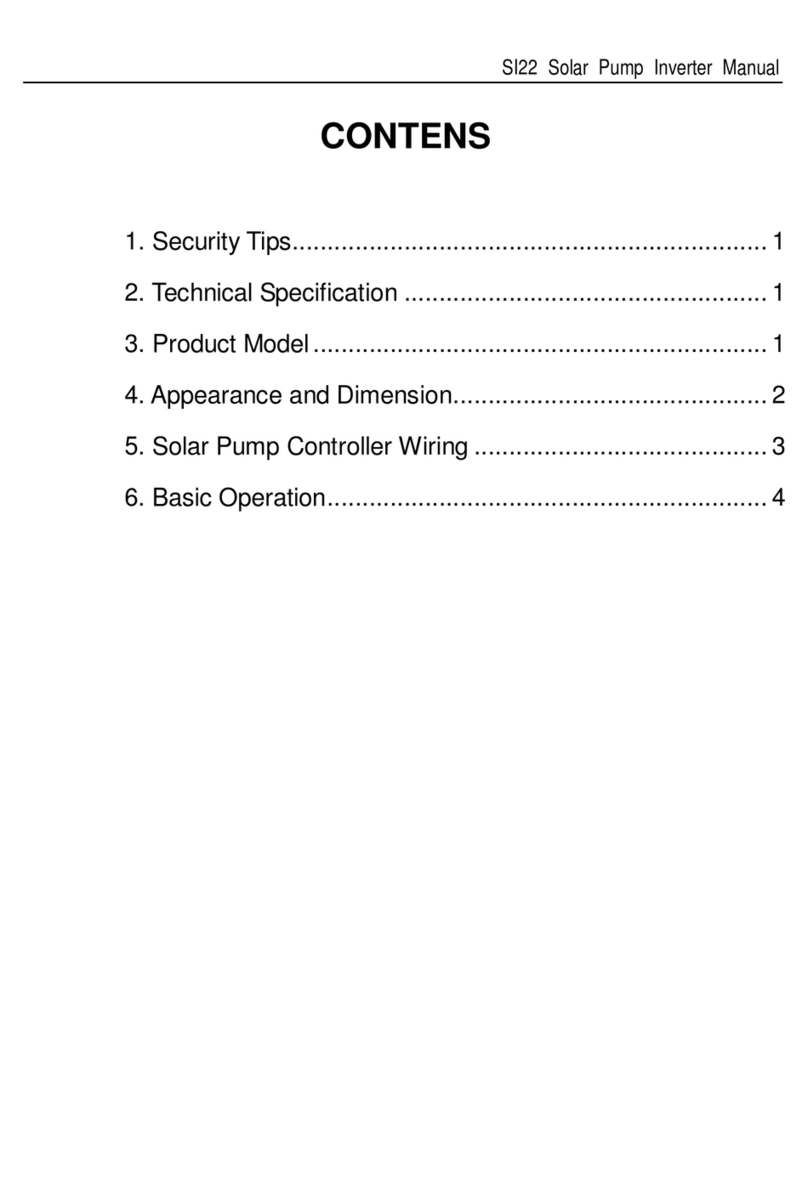

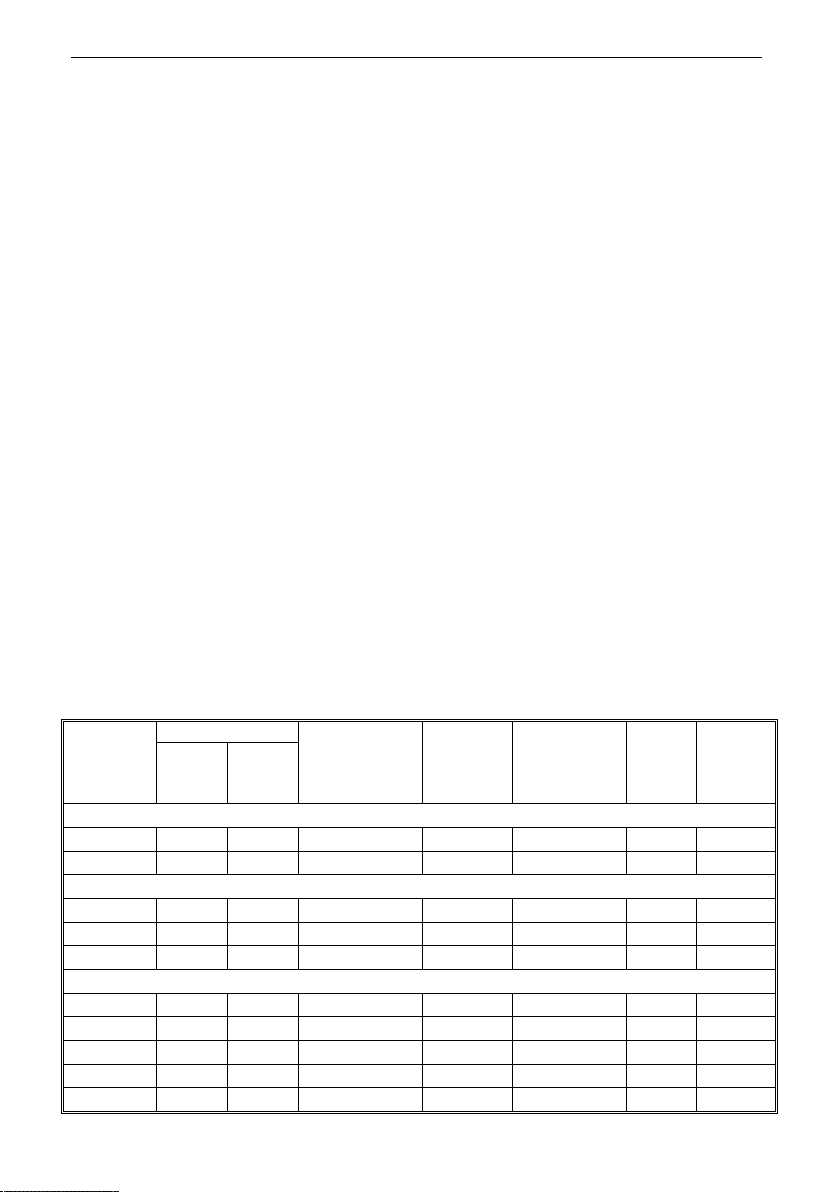

1.4 Technical Specification

Solar pump

inverter

power(kW)

Pump Max solar power

input

(kW)

Max DC

input

voltage (V)

Recommend

Voc voltage (V)

Rated

output

current

(A)

Output

frequency

(Hz)

Rated

power

(kW)

Rated

voltage

(V)

SI30-D1 series, DC90V-400V input,3 phase AC110V-230V output, MPPT voltage range DC90V-400V,for AC110V pumps

0.75 0.75 110 1.0 400 175~380 7A 0-320

1.5 1.5 110 1.95 400 175~380 10A 0-320

SI30-D3 series,DC150V-450V input,3 phase AC220V-240V output, MPPT voltage range DC150V-450V, for AC220V pumps

0.75 0.75 220 1.0 450 360~430 4A 0-320

1.5 1.5 220 1.95 450 360~430 7A 0-320

2.2 2.2 220 2.86 450 360~430 10A 0-320

SI30-D5 series,DC300V-850V input,3 phase AC230V-460V output, MPPT voltage range DC300V-800V,for AC380V pumps

0.75 0.75 380 1.0 850 620~750 2.5 0-320

1.5 1.5 380 2.2 850 620~750 3.7 0-320

2.2 2.2 380 3.3 850 620~750 5.0 0-320

4 3.7 380 5 850 620~750 10 0-320

5.5 5.5 380 8 850 620~750 13 0-320