1

Preface

Thank you for choosing SD700 series AC servo driver.

SD700 series AC servo driver is our general high-performance servo driver. This product adopts a series of

advanced motor control algorithms and 24 bits high precision encoder. It has the characteristics of high control precision,

fast tracking response, simple and convenient debugging. It can meet the function and performance of the high-end

servo application requirements. The product has built-in point control function, electronic cam, RS485 interface,

CANopen interface, 16 bit analog input and other rich application expansion functions. It can provide high reliability

and high cost performance solutions for machine tools, electronic equipment, robots, textiles, packaging and so on.

This manual only provides the introduction of safety precautions, installation and wiring, functional code sheets,

troubleshoot and countermeasures, and monitoring parameter description. Detailed functional annotations and

application notes refer to the SD700 series product manuals or consulting our company. This manual is the basic

guidance document for your proper use, giving full play to its superior performance and safe operation. Please read it

carefully and keep it properly, and hand it over to the end user of this product.

In the course of using, if you have any difficult problems or special requirements, please contact with our company

(Office) or distributor at any time. You can also contact our customer service center directly. We will serve you

wholeheartedly.

Our company has been committed to the continuous optimization of products. Therefore, this series of products and

related information may be optimized or changed, and there is possibility of change. If there is any change, no notice

will be given.

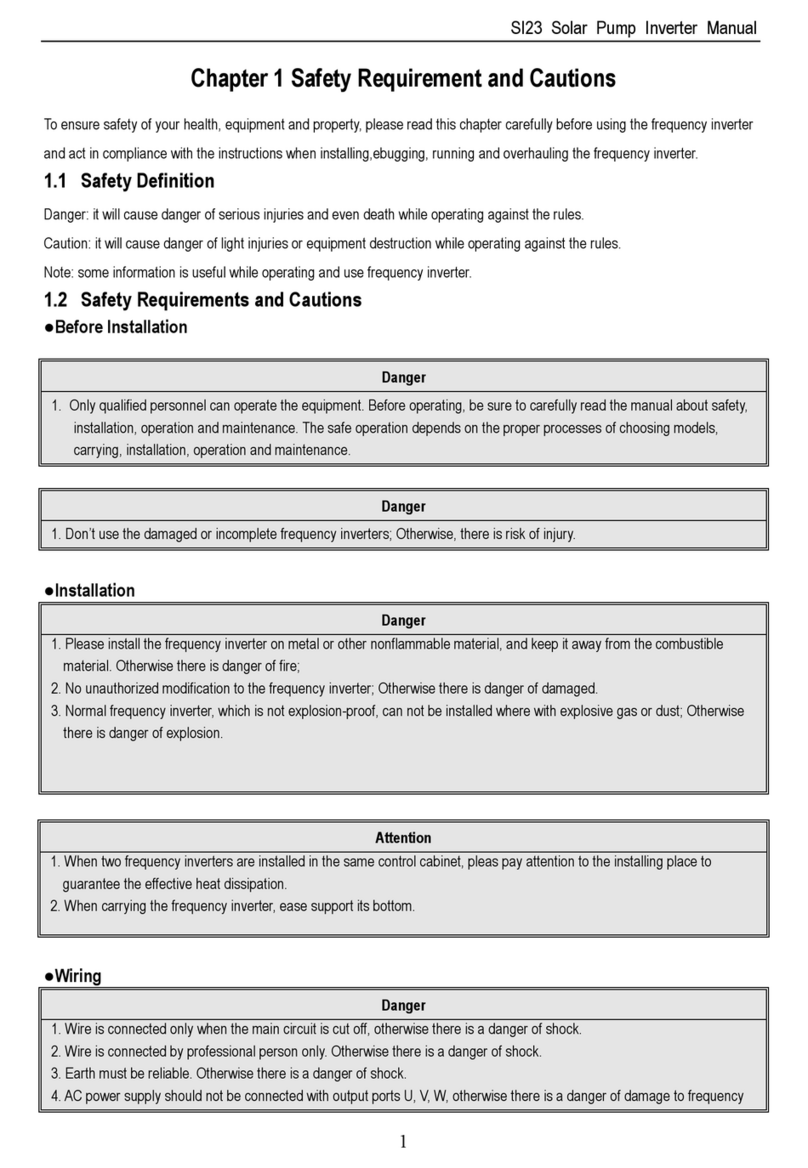

Safety precautions

To ensure the safe and reasonable use of this product, please use the product after fully understanding the safety

precautions described in this manual.

Operational qualification

This product must be operated by trained professionals. The operator must undergo professional skills training,

familiar with the installation, wiring, operation and maintenance of the equipment, and correctly deal with all kinds of

emergencies in use.

Safety guidance

The warning sign is for your safety. It is a measure to prevent operators from being injured and damage to this

product and associated system. Please read this manual carefully before use and strictly follow the safety rules and

warning signs in this manual.

Proper transportation, storage, installation and careful operation and maintenance are very important for the safe

operation of the servo system. During transportation and storage, the servo system must not be subjected to impact and

vibration, and must also be kept in dry, non corrosive gas, conductive dust and ambient temperature less than 60 degrees

Celsius.

This product has a dangerous voltage, and it is controlled by a potentially dangerous sports organization. If it fails

to comply with the regulations or does not comply with the requirements of this manual, it may lead to personal injury,

damage to the product and associated systems.

Do not connect with the power supply, otherwise you will be in danger of electrocution. When the wiring,

inspection, maintenance and other operations, please cut off the power of all associated devices, and confirm that the DC

voltage of the main circuit has dropped to a safe level, and then wait for 10 minutes to do the related work.

The power line, motor line and control line must be fastened and connected. The earthing terminals must be