SI23 Solar Pump Inverter Manual

4

inverter is zero when the switch is working)

6. At over 1,000 meters altitude, the inverter’s heat dissipation function worsened due to the thin air, it is necessary to use

less.

7. The inverter output voltage is pulse wave type. If using digital multi-meter measurement, deviation of the reading will be

great. And the deviation is different by using different type of digital multi-meter. Under normal circumstances, while RMS

380V, digital multi-meter reading is around 450V.

8. Solar panel can be connected in the series or parallel. For rated voltage 380V controller, we suggest working voltage

between 480V and 560V while MPPT. What means the solar panel open circuit voltage should be between 600V and

700V.

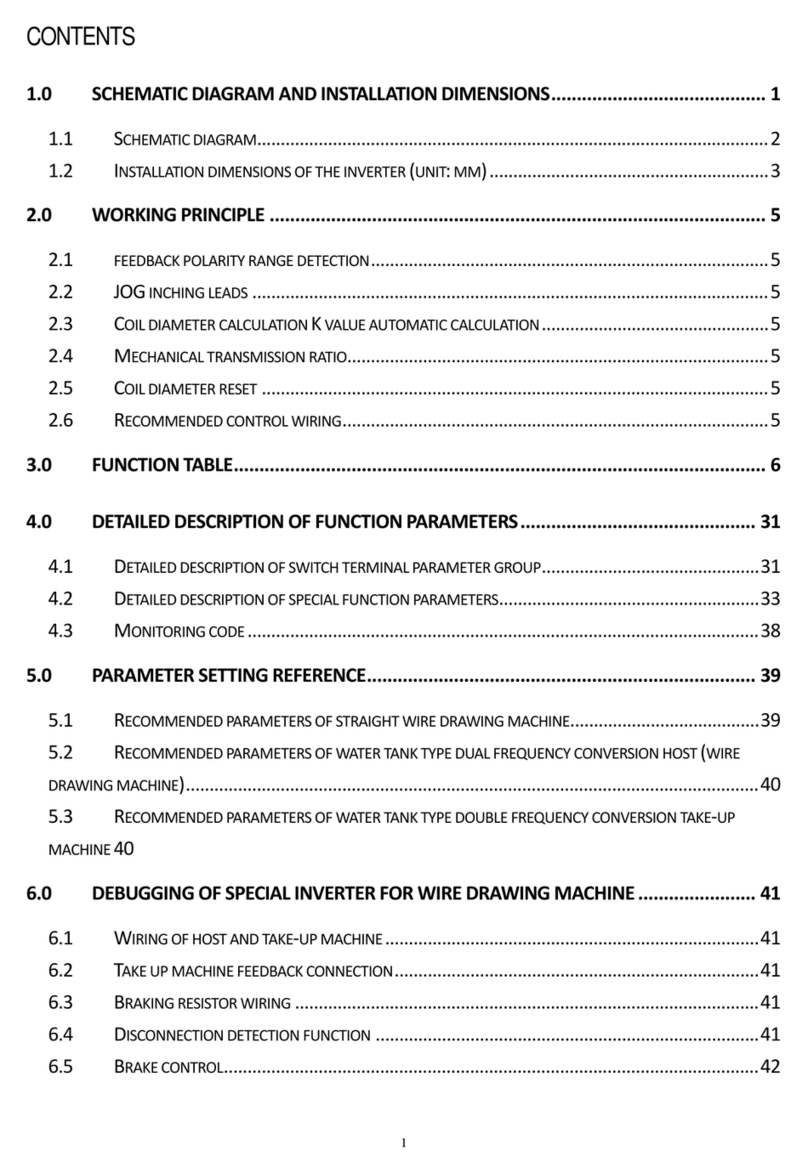

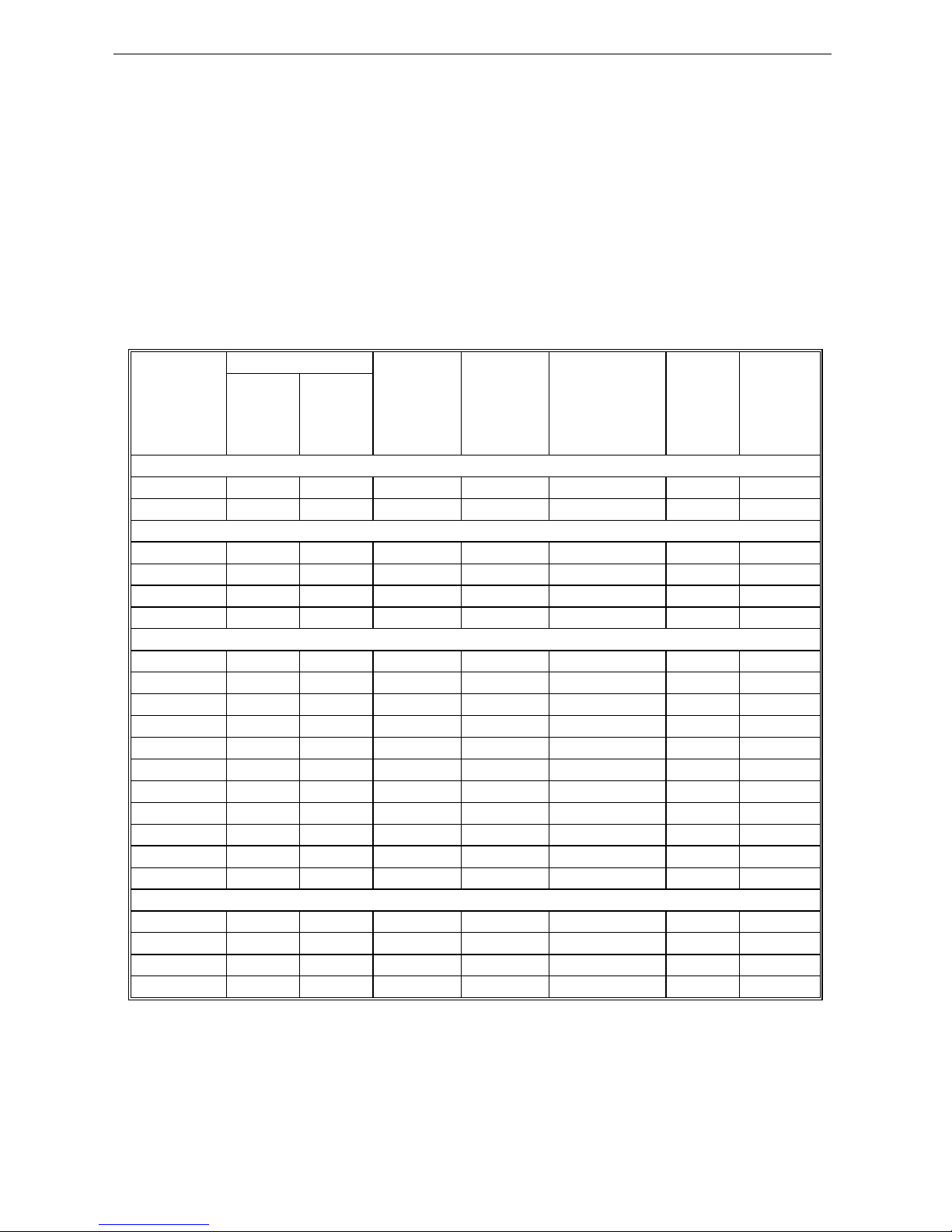

1.4 Technical Specification

Solar pump

inverter

power(KW)

Pump Max solar

power

input

(KW)

Max DC

input

voltage V

Recommend

Voc voltage (V)

Rated

output

current

(A)

Output

frequency

(Hz)

Rated

power

(KW)

Rated

voltage

(V)

SI23-D1 series, DC60-400VDC input, 3 phase 110-230VAC output

0.75 0.75 110 1.0 400 175~380 7A 0-600

1.5 1.5 110 1.95 400 175~380 10A 0-600

SI23-D3 series,DC150V-450V input, 3 phase 220-240VAC output

0.75 0.75 220 1.0 450 360~430 4A 0-600

1.5 1.5 220 1.95 450 360~430 7A 0-600

2.2 2.2 220 2.86 450 360~430 10A 0-600

4 4 220 5.4 450 360~430 16A 0-600

SI23-D5 series,DC250V to 780VDC input, 3 phase 380-460VAC output

0.75 0.75 380 1.0 780 620~750 3.0 0-600

1.5 1.5 380 2.2 780 620~750 4.0 0-600

2.2 2.2 380 3.3 780 620~750 6.0 0-600

4 4 380 5.6 780 620~750 10 0-600

5.5 5.5 380 8 780 620~750 13 0-600

7.5 7.5 380 10 780 620~750 17 0-600

11 11 380 14.3 780 620~750 25 0-600

15 15 380 19.5 780 620~750 32 0-600

18.5 18.5 380 23.4 780 620~750 38 0-600

22 22 380 28.6 780 620~750 45 0-600

30 30 380 39 780 620~750 60 0-600

SI23-T3 series,DC350V to 780VDC input,3phase 380-440VAC output

37 37 380 48.1 780 620~750 75 0-600

45 45 380 58.5 780 620~750 90 0-600

55 55 380 71.5 780 620~750 110 0-600

75 75 380 97.5 780 620~750 150 0-600

1.5 Cautions in Disposal

When you dispose frequency inverter, please pay attention to:

1. Electrolytic capacitor: the electrolytic capacitor of main circuit or the printing plate may explode when they are burned.

2. Plastic: plastic incineration may generate toxic gases.

3. Dispose method: please dispose as industrial waste.