AC70T 起重专用变频器使用说明书 目录

II

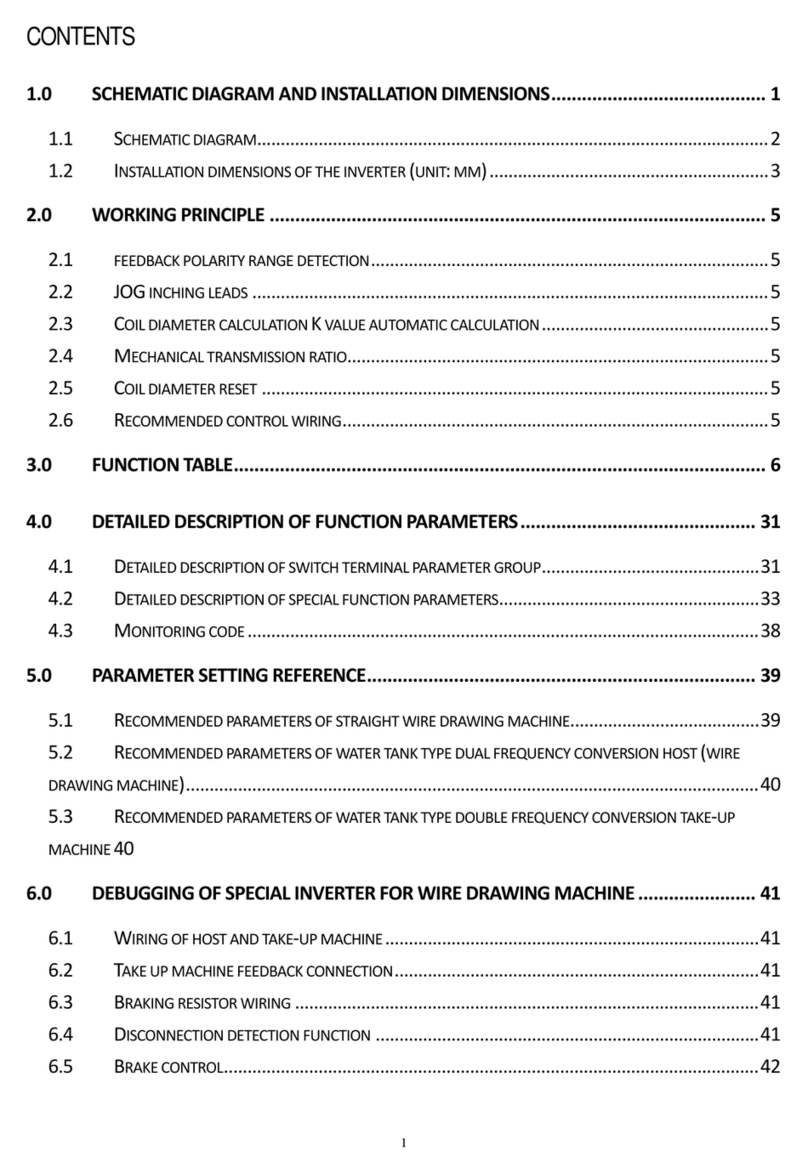

4.7 START AND SHUTDOWN COMMANDS ............................................................. 35

4.8 MULTI-SPEED SETTING ................................................................................ 36

4.9 ANALOG INPUT PORT .................................................................................... 37

4.10 ANALOG OUTPUT PORT ............................................................................... 37

5. DEDICATED FUNCTION DESCRIPTION ...............................................................39

5.1 BRAKE CONTROL ......................................................................................... 39

5.2 BRAKE FAILURE PROTECTION ....................................................................... 41

5.2.1 Function Description............................................................................. 41

5.2.2 Cautions ............................................................................................... 41

5.2.3 Related parameters.............................................................................. 41

5.3 BRAKE TORQUE DETECTION.......................................................................... 42

5.3.1 Activation method................................................................................ 42

5.3.2 Working Process................................................................................... 42

5.3.3 Related parameters.............................................................................. 42

5.4 CONSTANT POWER CONTROL ........................................................................ 43

5.5 SMOOTH LIFT ............................................................................................... 43

5.5.1 Function Description............................................................................. 44

5.5.2 Related parameters.............................................................................. 44

5.6 LIFTING AND ANTI-HANGING ........................................................................ 45

5.6.1 Working Process................................................................................... 45

5.6.2 Related parameters.............................................................................. 45

5.7 VARIABLE ANTI-SWAY .................................................................................. 46

5.7.1 Function Description............................................................................. 46

5.7.2 Operation guidance.............................................................................. 46

5.7.3 Related parameters.............................................................................. 47

5.8 ANT SPEED .................................................................................................. 48

5.9 SLEWING CONTROL ...................................................................................... 48

Note: Some rotary mechanisms are equipped with common motors with eddy

current brakes, the eddy current-free control solution is still recommended and

the eddy current coil on the motor side can be left unwired........................... 49

5.9.1 Eddy current free control ...................................................................... 49

5.9.2 With eddy current control..................................................................... 50

5.10 EDDY CURRENT CONTROL .......................................................................... 51