5

Aspen®Woodburning Stove

30003844

These should be an internal diameter of 150 mm (6”)

and be of the twin wall insulated construction that has

been approved for solid fuel use (e.g. Rite Vent ICS of

ICID Lite Chimney Systems). Diameters over 00 mm

(8”) are not recommended due to the large cross-sec-

tion causing excessive cooling of the ue gases.

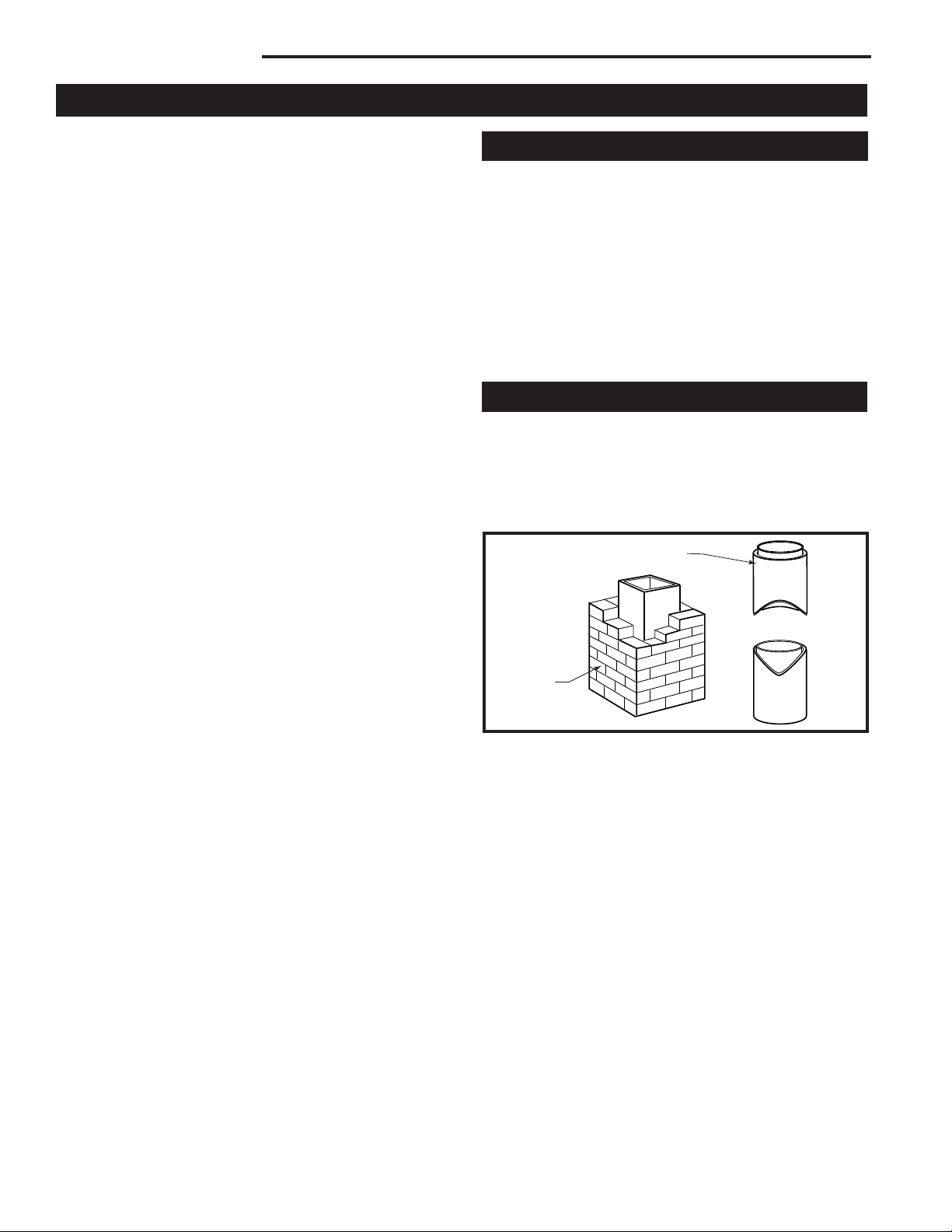

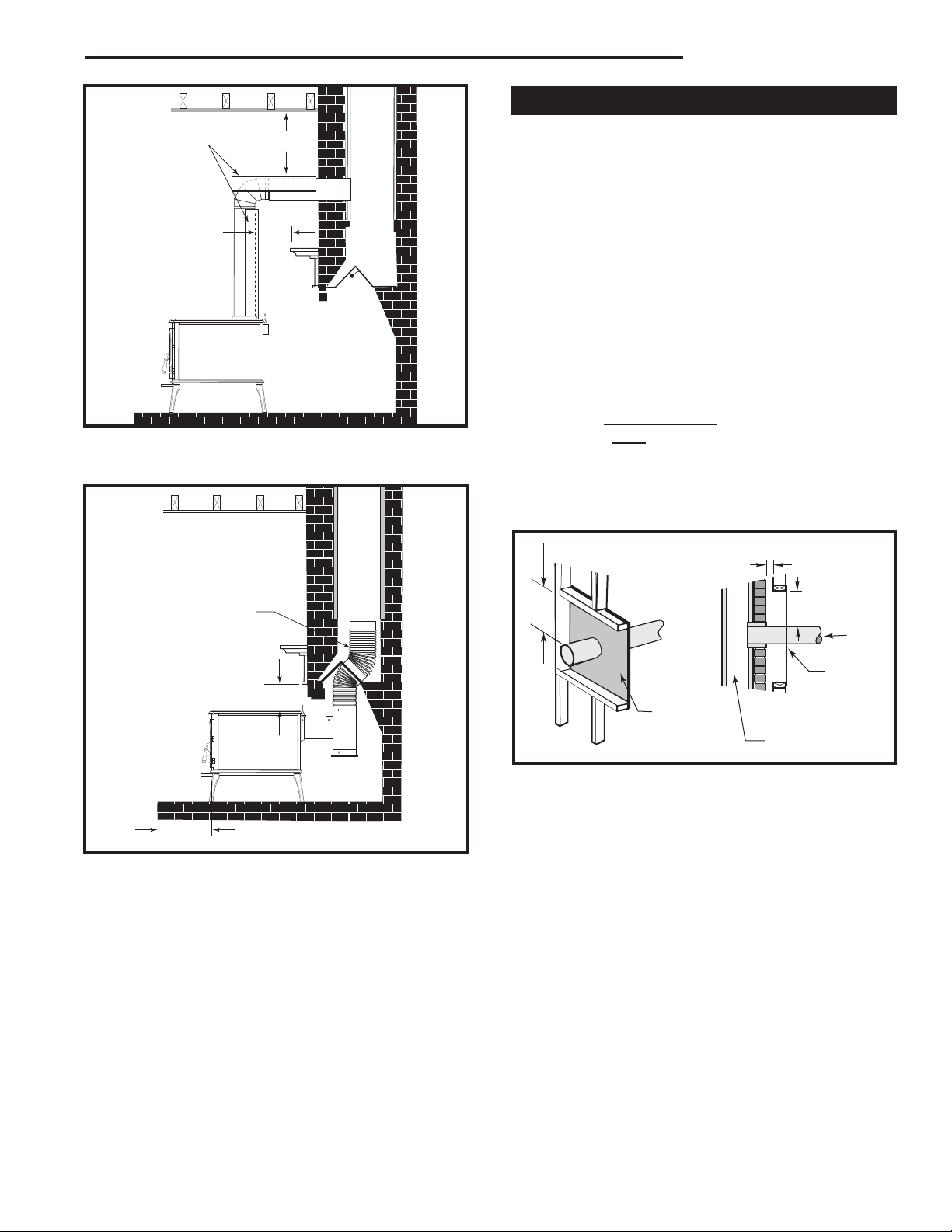

This stove is approved for venting into a masonry

chimney with a nominal ue size of 03 x 03 mm (8” x

8”), and into a round ue size of 03 mm (8”) or 15 mm

(6”).

It may be vented into larger chimneys as well. However,

chimneys with liners larger than 03 x 305 mm (8” x 1”)

may experience rapid cooling of smoke and reduction

in draft, especially if they are located outside the home.

Such large chimneys may need to be insulated or have

the ue relined for proper stove performance.

Ask your dealer about components available for con-

necting the stove to a steel chimney liner.

A chimney connector is the double-wall or single-wall

pipe that connects the stove to the chimney. The chim-

ney itself is a masonry or prefabricated structure that

encloses the ue. Chimney connectors are used only

to make the connection from the stove to the chimney.

They are for interior use only.

Connector pipes should meet the requirements of the

building regulations. This can be achieved by the use

connecting uepipes included in the following catego-

ries:

a) Vitreous enamelled steel pipe complying with BS

6999: 1989 (1996);

b) Pipes made from stainless steel as descirbed in BS

EN 1008-1:1995 grades 1.4401, 1.4404, 1.443 or

1.4436 with ue wall thickness of at least 1 mm;

c) Mild steel uepipes complying with BS 1449: Part 1:

1991, with a ue wall thickness of at least 3 mm;

d) Cast iron uepipes complying with BS 41: 1973

(1998).

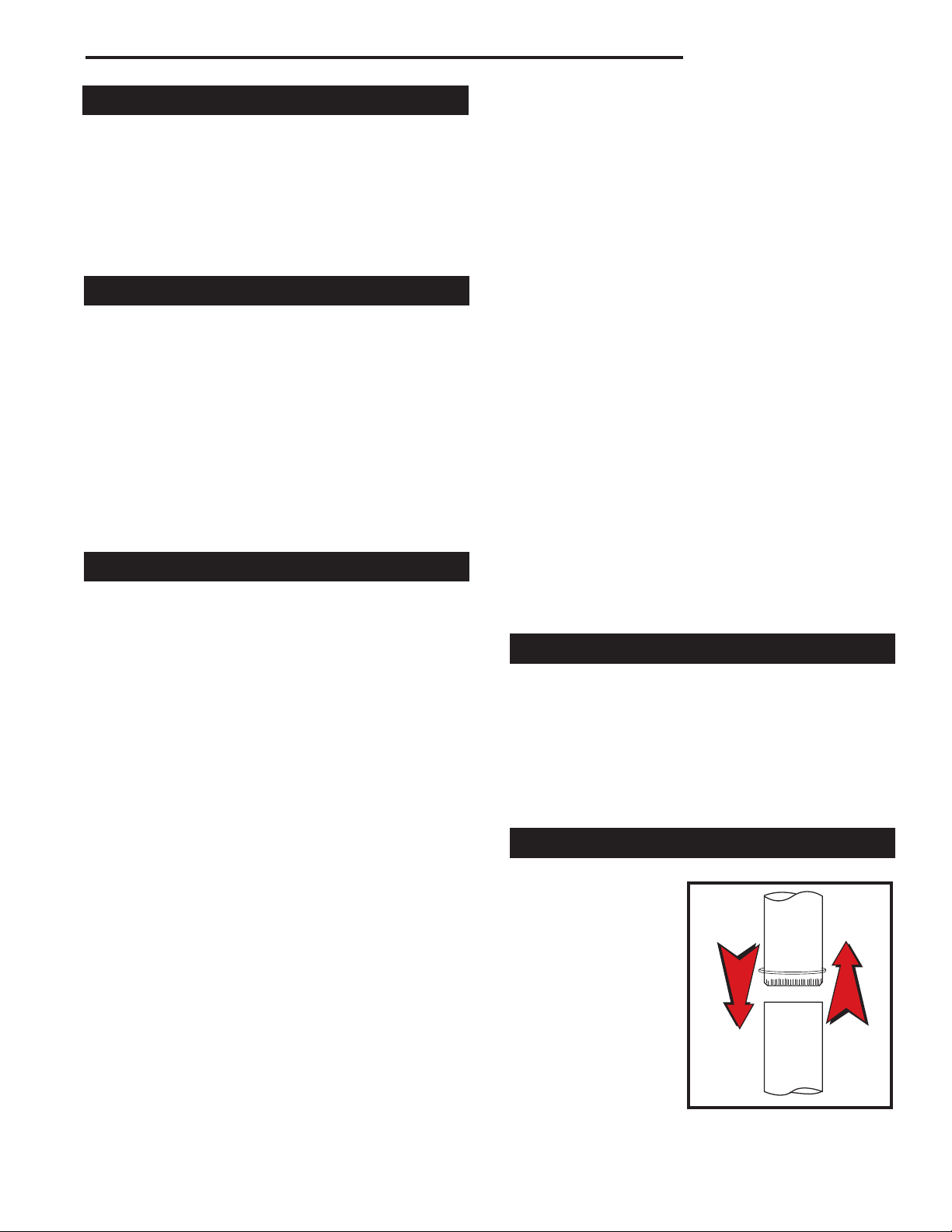

Flue Pipes with a spigot and socket joint should be

tted with the socket facing upwards, to contain con-

densates and moisture within the ue. Joints should be

made gas tight using proprietary jointing accessories,

or, where appropriate, by packing joint with noncombus-

tible rope and re cement.

Double-wall connectors must be tested and listed for

use with solid-fuel burning appliances. Single-wall con-

nectors should be made of 4 gauge or heavier steel,

and should be 15 mm (6”) in diameter. Do not use

galvanized chimney connector; it cannot withstand the

high temperatures that can be reached by smoke and

exhaust gases, and may release toxic fumes under high

heat.

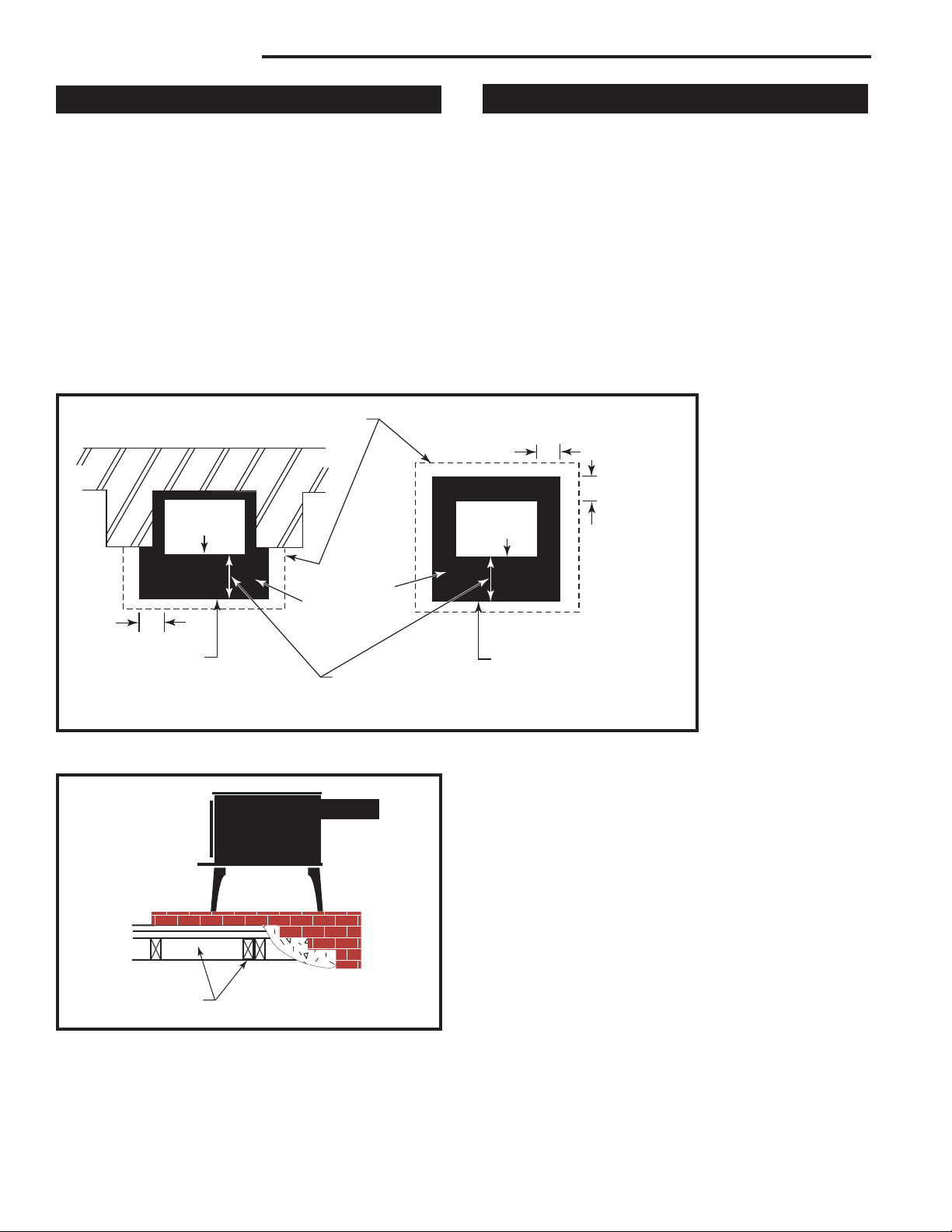

If possible, do not pass the chimney connector through

a combustible wall or ceiling. If passage through a

combustible wall is unavoidable, refer to the recommen-

dations in the section following on Wall Pass-throughs.

Do not pass the connector through an attic, a closet or

any similar concealed space. The whole chimney con-

nector should be exposed and accessible for inspection

and cleaning.

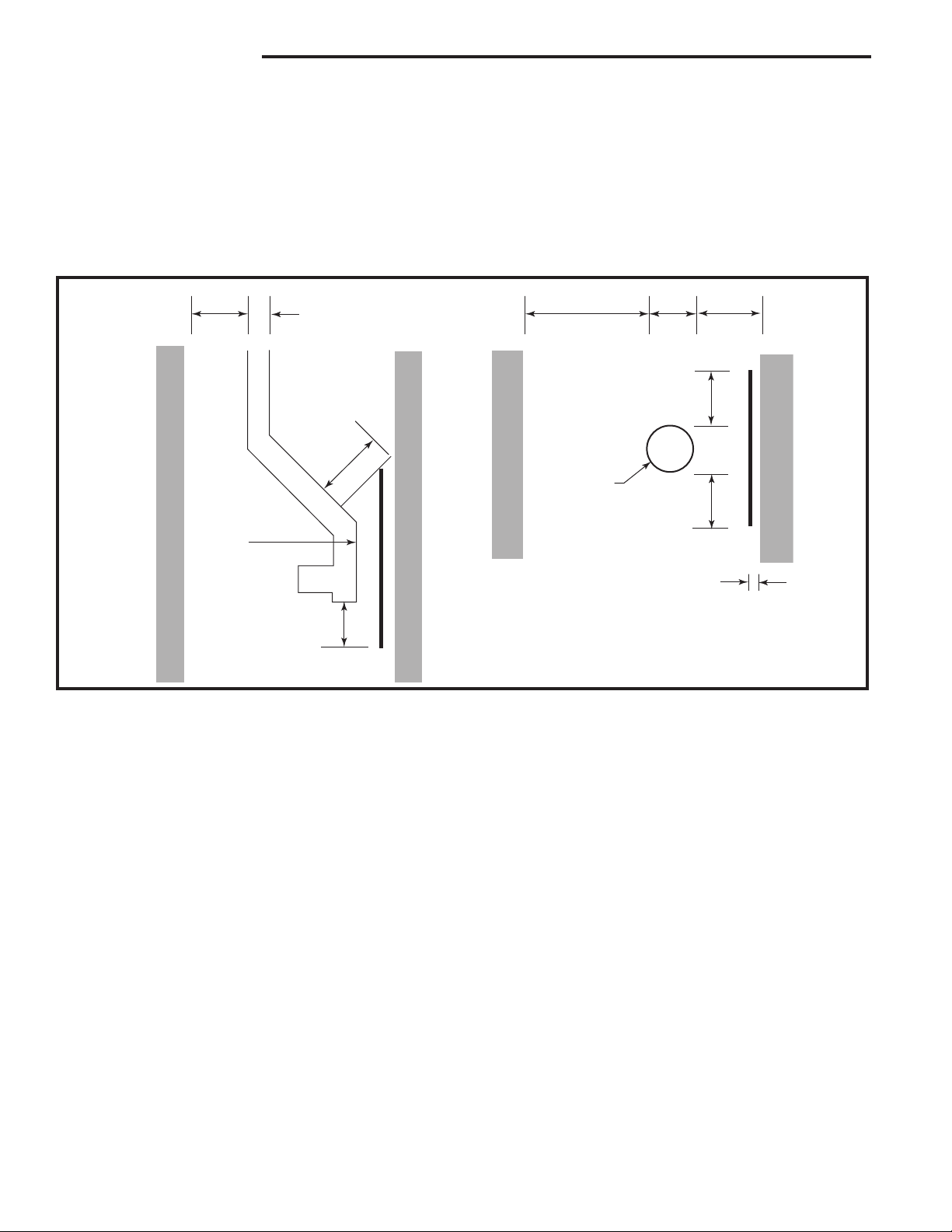

Install the single wall chimney connector not less than

457 mm (18”) from the ceiling. Keep it as short and

direct as possible, with no more than two 90 degree

turns. If possible, use 45° elbows. Slope horizontal runs

of connectors upward 0 mm per meter (1/4” per foot)

going from the stove toward the chimney. The recom-

mended maximum length of a horizontal run is 914 mm

(36”), and the total length of chimney connector should

be no longer than .5 m (8’).

In cathedral ceiling installations, extend the prefabricat-

ed chimney downward to within .5 m (8”) of the stove.

Follow the instructions for assembling and installing

double-wall connectors provided by the manufacturer

of the double-wall chimney. To ease assembly and help

assure safety, use chimney components manufactured

by a single source.

• Beginning at the ue collar of the stove, assemble

the chimney con-

nector. Insert the

rst crimped end

into the stove’s ue

collar, and keep

each crimped end

pointing toward the

stove. Using the

holes in the ue

collar as guides,

drill 1/8” (3 mm)

holes in the bottom

of the rst section

Toward

stove

Chimney connector.

ST242

Chimney connector

12/13/99 djt

Flue gas

direction