5

Aspen®Woodburning Stove

30000369

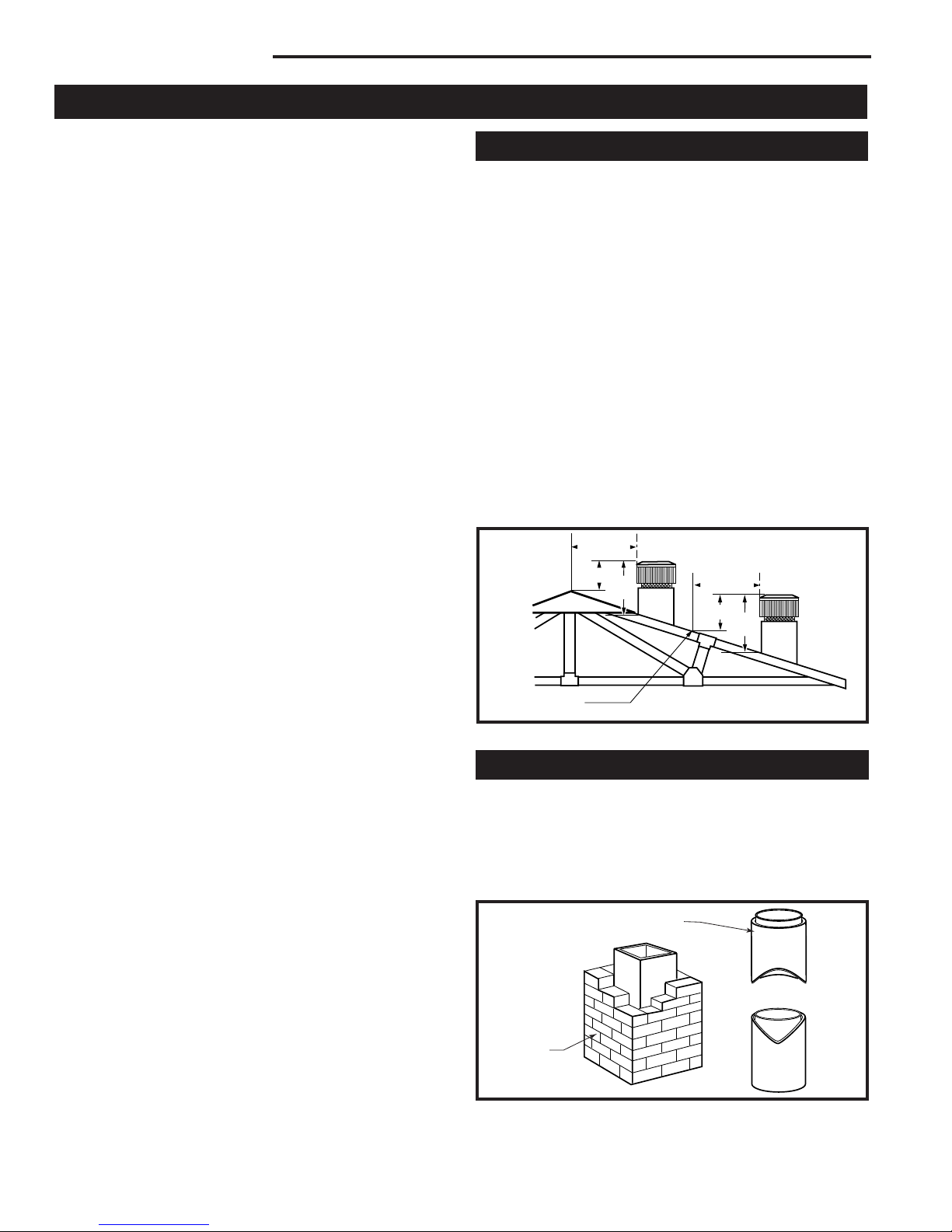

• Unused openings in an existing masonry chimney must

be sealed with masonry to the thickness of the chimney

wall, and the chimney liner should be repaired. Open-

ings sealed with pie plates or wallpaper are a hazard

and should be sealed with mortar or refractory cement.

In the event of a chimney re, ames and smoke may

be forced out of these unused thimbles.

• The chimney should be thoroughly cleaned before

use.

• A newly-built masonry chimney must conform to the

standards of local building code, or, in the absence of

a local code, to a recognized national code. Masonry

chimneys must be lined, either with code-approved

masonry or precast refractory tiles, stainless steel pipe,

or a code-approved, “poured-in-place” liner. The chim-

ney clean-out door must seal tightly to ensure a good

draft.

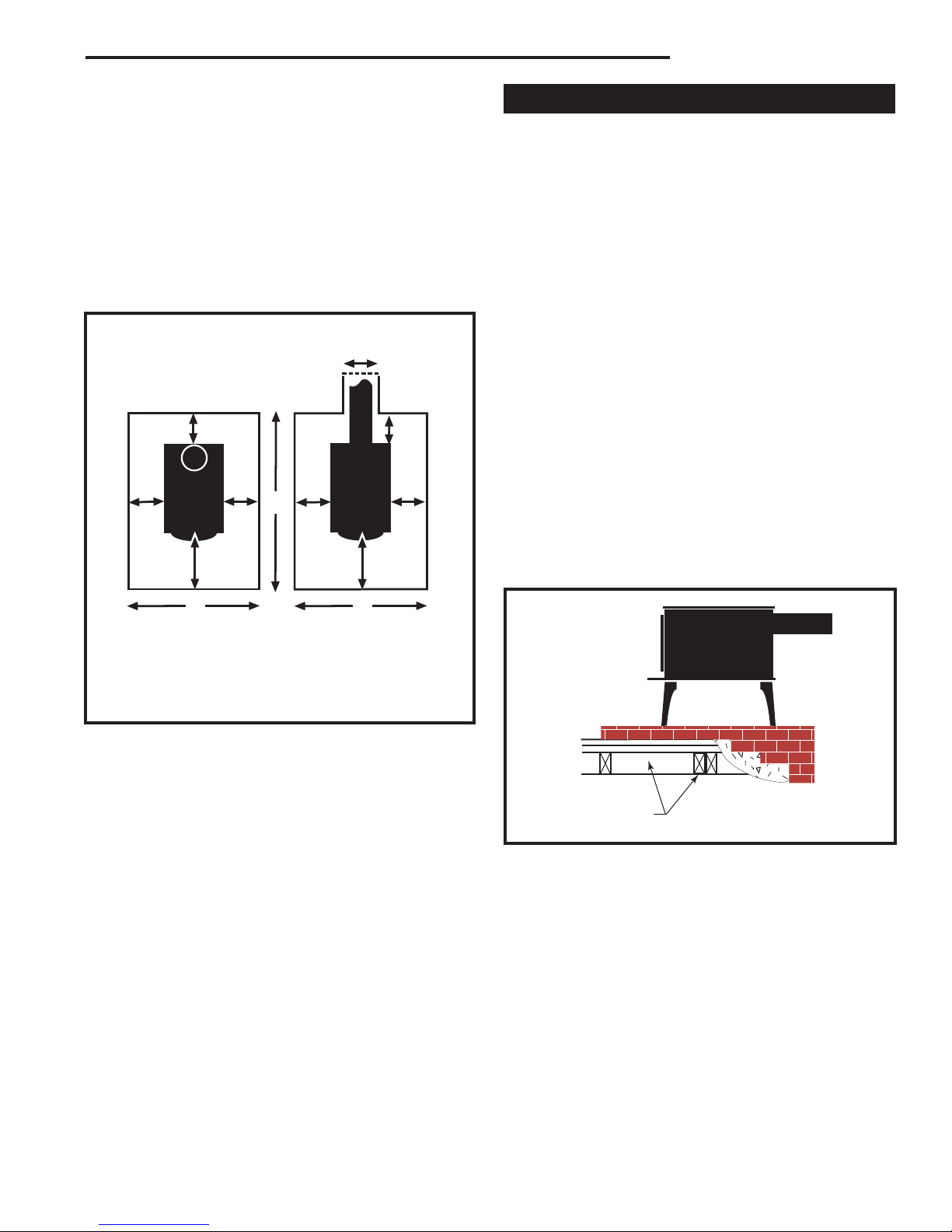

A prefabricated metal chimney must be one that is tested

and listed for use with solid-fuel burning appliances to the

High-Temperature (H.T.) Chimney Standard UL-103-1985

(2100°F.) for the United States, and High Temperature

(650°C) Standard ULC S-629 for Canada.

This stove is approved for venting into a masonry chimney

with a nominal ue size of 8” x 8” (203 x 203 mm), and into

a round ue size of 8” (203 mm) or 6” (152 mm).

It may be vented into larger chimneys as well. However,

chimneys with liners larger than 8” x 12” (203 x 305 mm)

may experience rapid cooling of smoke and reduction in

draft, especially if they are located outside the home. Such

large chimneys may need to be insulated or have the ue

relined for proper stove performance.

Ask your dealer about components available for connecting

the stove to a steel chimney liner.

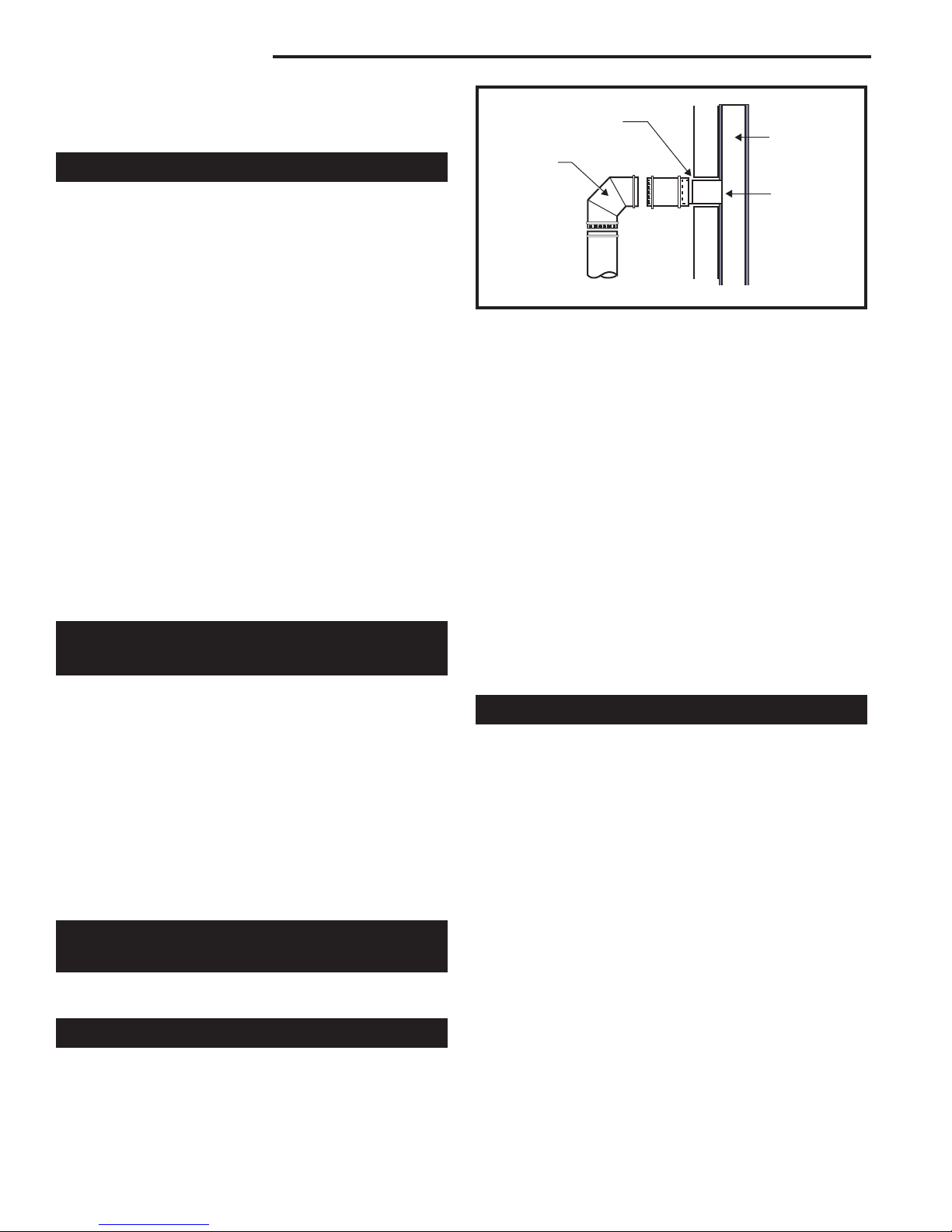

A chimney connector is the double-wall or single-wall pipe

that connects the stove to the chimney. The chimney it-

self is a masonry or prefabricated structure that encloses

the ue. Chimney connectors are used only to make the

connection from the stove to the chimney. They are for

interior use only.

Double-wall connectors must be tested and listed for use

with solid-fuel burning appliances. Single-wall connectors

should be made of 24 gauge or heavier steel, and should be

6” (152 mm) in diameter. Do not use galvanized chimney

connector; it cannot withstand the high temperatures that

can be reached by smoke and exhaust gases, and may

release toxic fumes under high heat.

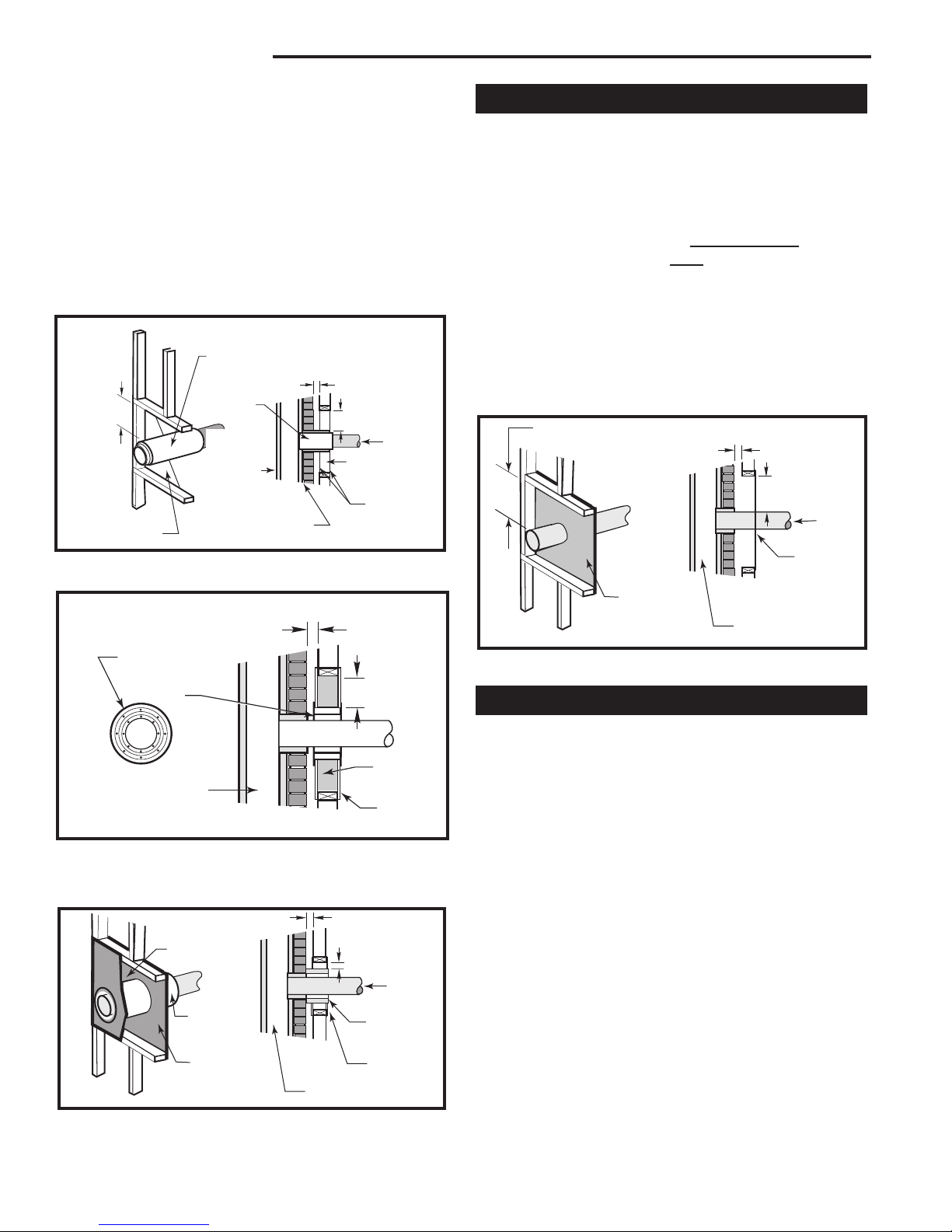

If possible, do not pass the chimney connector through

a combustible wall or ceiling. If passage through a com-

bustible wall is unavoidable, refer to the recommendations

in the section following on

Wall Pass-throughs. Do

not pass the connector

through an attic, a closet

or any similar concealed

space. The whole chim-

ney connector should be

exposed and accessible

for inspection and clean-

ing.

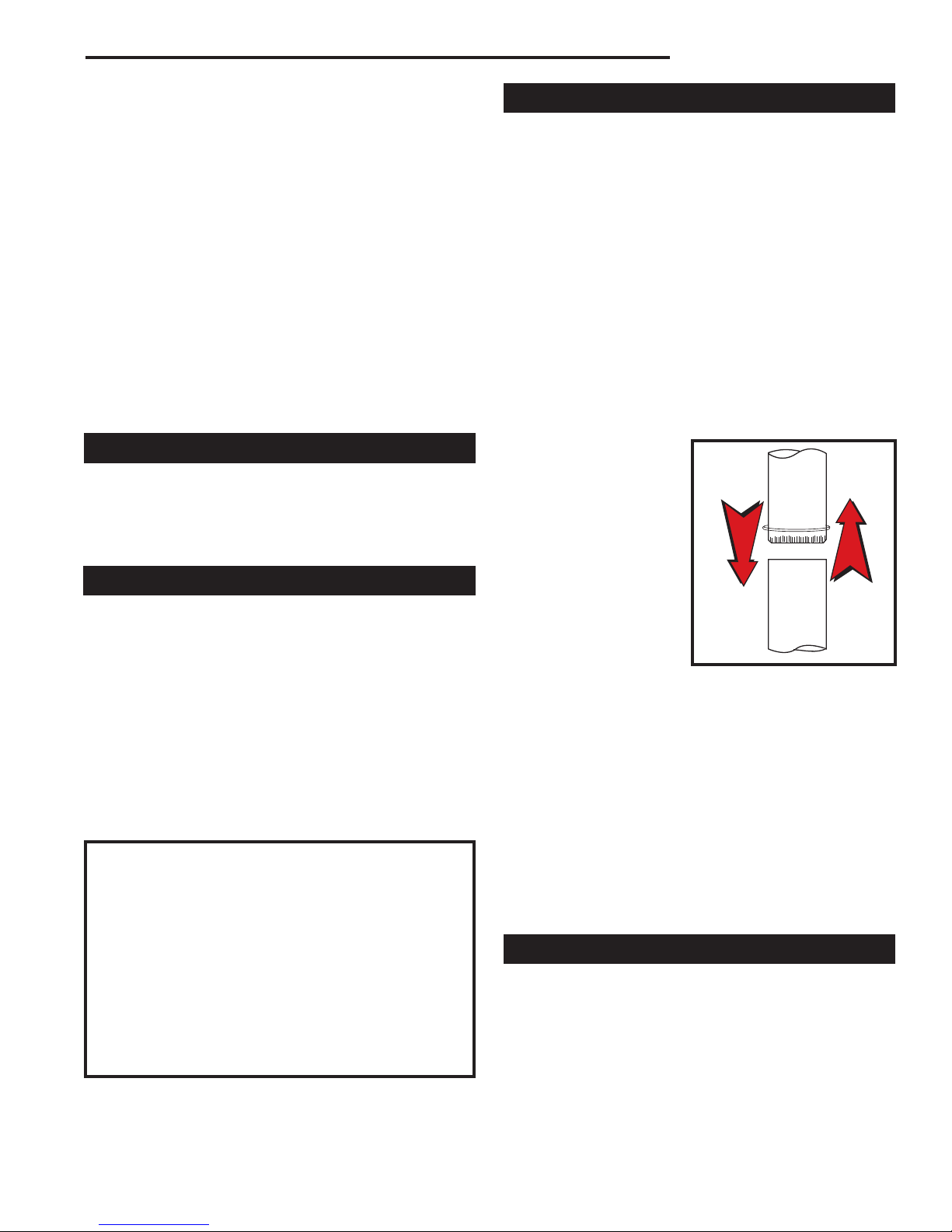

Install the single wall chim-

ney connector not less

than 18” (457 mm) from

the ceiling. Keep it as

short and direct as possible, with no more than two 90

degree turns. If possible, use 45° elbows. Slope horizontal

runs of connectors upward 1/4” per foot (20 mm per meter)

going from the stove toward the chimney. The recom-

mended maximum length of a horizontal run is 3’ (914

mm), and the total length of chimney connector should be

no longer than 8’ (2.5 meters).

In cathedral ceiling installations, extend the prefabricated

chimney downward to within 8 feet (2.4m) of the stove.

The Aspen is approved for installation in the U.S. and

Canada with double-wall chimney connectors that have

been tested and listed for use with solid-fuel burning ap-

pliances by a recognized testing laboratory.

Follow the instructions for assembling and installing

double-wall connectors provided by the manufacturer of

the double-wall chimney. To ease assembly and help as-

sure safety, use chimney components manufactured by a

single source.

ST242

Chimney connector

12/13/99 djt

Flue gas

direction

Toward

stove

Chimney connector.