6

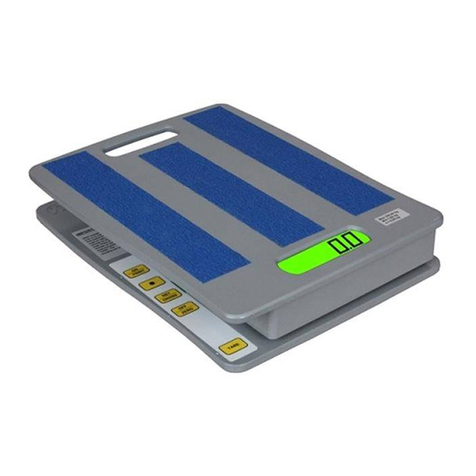

Function Keys

On/Print

Press and hold for two seconds to turn the unit on. When the unit is on, this key is

used to send weight information out to the serial port provided the following cond

i-

tions are met:

1.

The scale is not in motion.

2.

The scale is not

in overload (see error codes)

.

Hold

operation:

Coming soon

Calibration

Your

WB5040

-

SWP

portable

scale is ready to use right out of the box. There is no need to

calibrate the scale unless you feel that the scale has become inaccurate. It is a good idea

to check the calibration of your scale from time to time with a

precision

test weight.

1.

Switch

off the

display

unit by pressing and holding the ZERO/OFF key for about 5 seconds.

2.

Enter the Setup mode by pressing and holding the ON/PRINT key for about 20 seconds or

until the screen shows “SETUP”.

3.

While in the Setup mode, scroll to "F 16

",

and then scroll down once using the

ZERO/OFF key to enter zero calibration menu. The display will momentarily show "C 0" fo

l-

lowed by a value. This value is the internal A/D count and can prove useful when trying to

troubleshoot setup problems.

4.

Remove all items from the beams and press the ZERO

/OFF

key to zero out the dis

played

va

l

ue.

5.

Press the NET/GROSS key to save the zero point value. The display will show "

EndC0

"

momentar

ily, and then revert back up to F16.

6.

Press the ON/PRINT key to progress to the F17 menu.

7.

While at the

"

F 17

"

screen

, scroll down once using the ZERO/OFF key to enter span calibr

a-

tion menu. The display will momentarily show "C 1" for the span calibration point, followed

by a value with one flashing digit.

8.

Place the test weight on the weighing platform.

9.

Use the four directional keys to adjust the displayed value to the actual test weight value.

Increase the flashing digit by pressing the

UNITS

key. Decrease the flashing digit by pres

s-

ing the ZERO/OFF key. Pressing the

TARE

key or the

ON/PRINT

key will change the pos

i-

tion of the flashing digit.

10.

After entering the exact value, press the NET/GROSS key to save the value. If the calibr

a-

tion was successful, the display will show "

EndC1

" momentarily, followed by "C 2" for the

second calibration point.

11.

Repeat steps 8-10 for C2 and C3. At the conclusion of C3, the indicator

displays

the

current

gravity settings, e.g. “9.800”.

12.

P

ress the NET/GROSS key

to

revert

back up to F17

.