Vetek JWL-1 User manual

Other Vetek Scale manuals

Vetek

Vetek WLC 1/A2 User manual

Vetek

Vetek VRS-300 User manual

Vetek

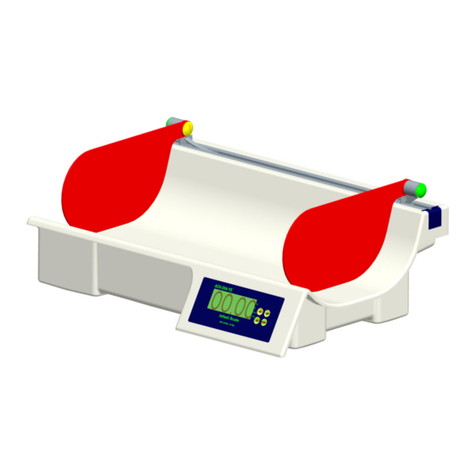

Vetek BABY 630 User manual

Vetek

Vetek WB5040-SWP User manual

Vetek

Vetek FR-H-100 User manual

Vetek

Vetek FR-MS User manual

Vetek

Vetek VRH-300 User manual

Vetek

Vetek ACS 20AYE User manual

Vetek

Vetek OCS-XZ-003 User manual

Vetek

Vetek SELL User manual

Vetek

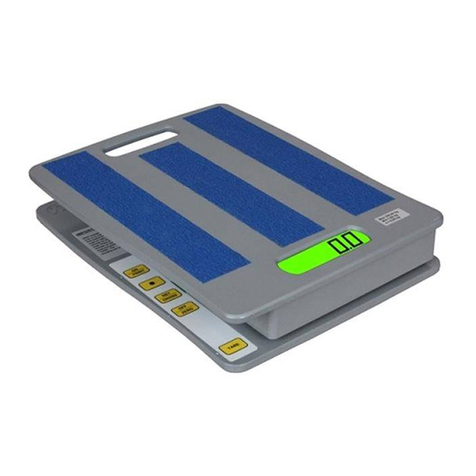

Vetek VB2 Series User manual

Vetek

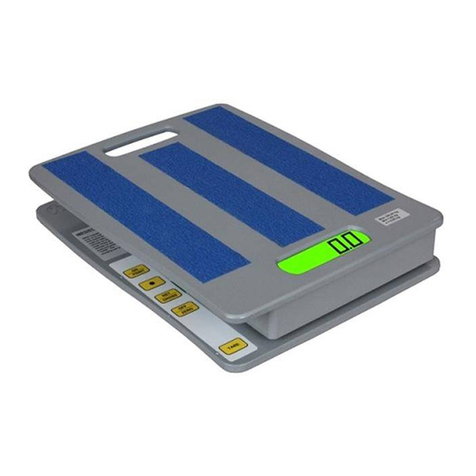

Vetek VB2 Series User manual

Vetek

Vetek OCS-M User manual

Vetek

Vetek JKD 250 User manual

Vetek

Vetek VRB-250 User manual

Vetek

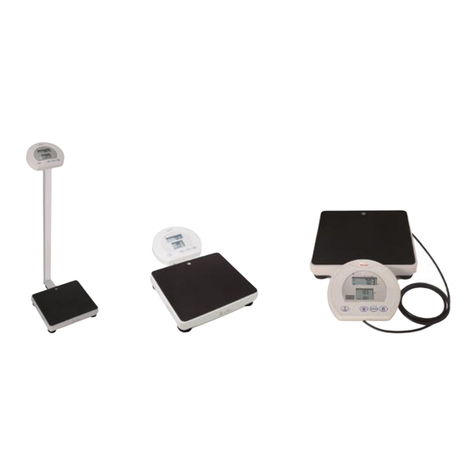

Vetek CW263BT User manual

Vetek

Vetek ERT DYNALINK User manual

Vetek

Vetek VRB-20 User manual

Vetek

Vetek WBA-300 User manual

Vetek

Vetek LPWN-1530 User manual