TABLEOFCONTENTS

HazardIdentification......................................1

Installer Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

General..............................................2

MaintenanceandTesting.................................2

Introduction.............................................2

TrimDimensions .........................................3

Exploded View Drawing – Trim Components . . . . . . . . . . . . . . . . . . . . 4

Exploded View Drawing – Internal Valve Components. . . . . . . . . . . . . . 6

Description - AutoConvert Trim Assembly . . . . . . . . . . . . . . . . . . . . . . 7

Latching Solenoid Module Cutaway . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Section View Drawing and Description –

Series 776 Low-Pressure Actuator . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Section View Drawing and Description –

Series 746-LPA Dry Accelerator. . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

AirSupplyRequirements..................................10

CompressorSizing.....................................10

Base or Riser-Mounted Air Compressors . . . . . . . . . . . . . . . . . . . . 10

Victaulic Series 757P Air Maintenance Trim Assembly

(AMTA) with Pressure Switch Option . . . . . . . . . . . . . . . . . . . . . 10

Shop Air or Tank-Mounted Air Compressors. . . . . . . . . . . . . . . . . . 11

Victaulic Series 757 Regulated Air Maintenance

Trim Assembly (AMTA) Option . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Compressor Requirements and Settings for

Series 769 FireLock NXT Preaction Valves

Installed with Series 746-LPA Dry Accelerators . . . . . . . . . . . . . 11

Settings for Air Supervisory Pressure Switches

and Alarm Pressure Switches . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Remote System Test Valve Requirements. . . . . . . . . . . . . . . . . . . . 11

Important Installation Information . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Valve/TrimInstallation ....................................12

Compression Fitting and Tube Installation . . . . . . . . . . . . . . . . . . . 12

HydrostaticTesting ......................................12

System Sensor PDRP-2001 Field Wiring Diagram (Standard). . . . . . . 14

System Sensor PDRP-2001 Field Wiring Diagram

(Standard, Low-Pressure Switch - Double-Interlocked,

Electric-Pneumatic/Electric) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Potter PFC-4410RC Field Wiring Diagram (Standard). . . . . . . . . . . . . 16

Potter PFC-4410RC Field Wiring Diagram

(Standard, Low-Pressure Switch - Double-Interlocked,

Electric-Pneumatic/Electric) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Sample Program for System Sensor PDRP-2001 Panel . . . . . . . . . . . 18

Sample Program for Potter Signal PFC-4410RC Panel . . . . . . . . . . . . 19

Placing the System in Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

ExternalInspection ......................................26

WeeklyInspection.....................................26

MonthlyInspection ....................................26

RequiredTests..........................................27

MainDrainTest.......................................27

WaterFlowAlarmTest..................................28

AutoConvertSystemTest................................29

Water Level and Low Air Alarm Tests . . . . . . . . . . . . . . . . . . . . . . . 32

Required Operational (Trip) Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Partial Operational (Trip) Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Full Operational (Trip) Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Required Internal Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Maintenance...........................................41

Removing and Replacing the Clapper Seal. . . . . . . . . . . . . . . . . . . 41

Removing and Replacing the Clapper Assembly. . . . . . . . . . . . . . . 43

Installing the Cover Plate Gasket and Cover Plate. . . . . . . . . . . . . . 45

Removing and Replacing the Diaphragm Assembly . . . . . . . . . . . . 46

Replacing the Strainer Screen for Series 776

Low-PressureActuators...............................47

Troubleshooting – Series 776 Low-Pressure Actuator . . . . . . . . . . . . . 48

Troubleshooting – Series 746-LPA Dry Accelerator. . . . . . . . . . . . . . . 48

Troubleshooting – Series 753-E Solenoid Valve . . . . . . . . . . . . . . . . . 48

Troubleshooting – AutoConvert Trim Assembly. . . . . . . . . . . . . . . . . . 48

Troubleshooting–System .................................49

HAZARD IDENTIFICATION

Definitions for identifying the various hazard levels are

provided below. When you see this symbol, be alert to the

possibility of personal injury. Carefully read and fully

understand the message that follows.

WARNING

• Theuseoftheword“WARNING”identifiesthepresence

ofhazardsorunsafepracticesthatcouldresultindeathor

seriouspersonalinjuryifinstructions,includingrecommended

precautions,arenotfollowed.

CAUTION

• Theuseoftheword“CAUTION”identifiespossiblehazardsor

unsafepracticesthatcouldresultinpersonalinjuryandprod-

uctorpropertydamageifinstructions,includingrecommended

precautions,arenotfollowed.

NOTICE

• Theuseoftheword“NOTICE”identifiesspecialinstructions

thatareimportantbutnotrelatedtohazards.

REV_B

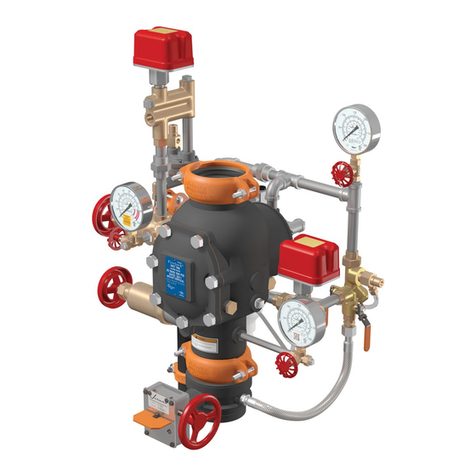

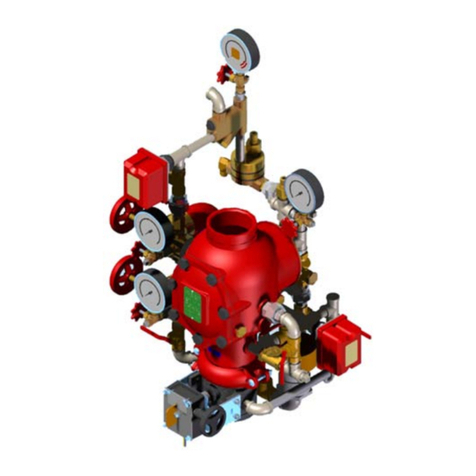

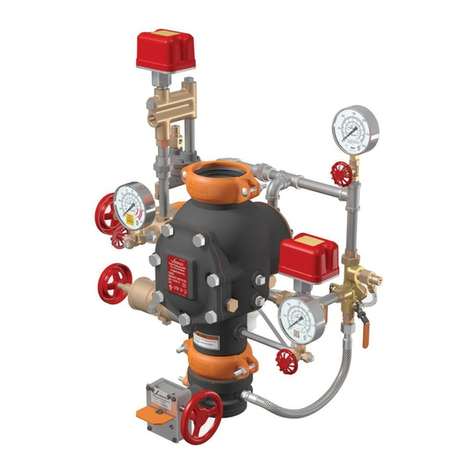

FireLockNXT™AutoConvertPreactionValve

SERIES 769

PreactionElectricAutoConvertDryTrim

I-769P.AC/ELEC

INSTALLATION,MAINTENANCE,ANDTESTINGMANUAL

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2009 VICTAULIC COMPANY. ALL RIGHTS RESERVED. PRINTED IN THE USA.

I-769P.AC/ELEC_1