Art.4800 - 4800M - Installation instructions

BUZZER BACK EMF

When using intercoms with buzzer call (Art.924/926, SMART1/2, 3101/2, 3001/2 and 3021/2) add one 0.1uF (100nF) capacitor be-

tween terminals 3 and 6 on the telephone.

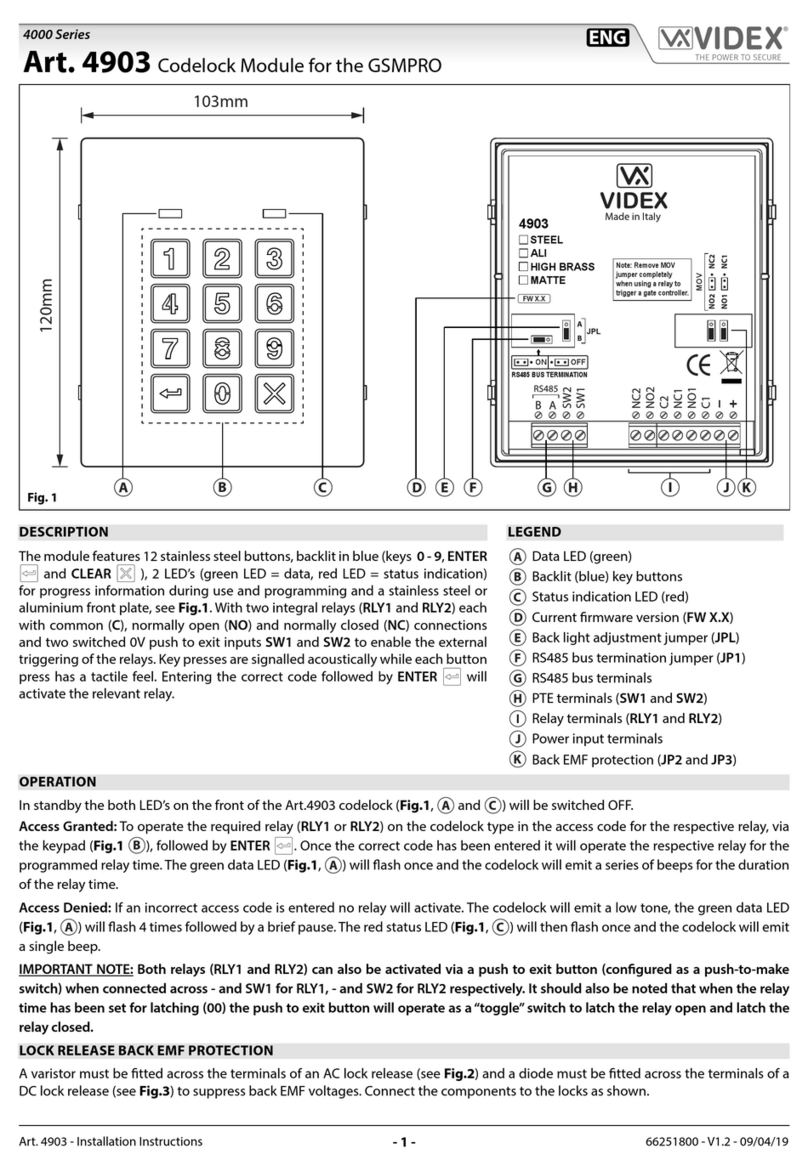

BUILTIN RELAYS BACK EMF PROTECTION ART.4800M

The Art.4800M includes selectable back EMF protection on the relays. The jumpers marked MOV (One jumper for each relay) are

used to select the protection type. When using a fail secure lock with connections C & NO the jumper should be in the NO position.

When using a fail open lock with connections C & NC the jumper should be in the NC position and when using the codelock to

trigger a gate controller or another third party controller the jumper should be removed completely (This disables the protection

on the relay).

PROGRAMMING SEE ALSO THE RELEVANT FLOW CHART

• Enter the“ENGINEER’S CODE”: rst time type six times“1”(111111 factory preset) and press “ENTER” (The red LED will illuminate);

• Conrm“ENGINEER’S CODE”(typing again the same) or type the new code (4 to 8 digits) then press “ENTER” (Melody). Pressing

twice the “ENTER” button without changing the “ENGINEER’S CODE”, will exit from the programming;

• Enter the code (4 to 8 digits) to enable “RELAY 1” or re-enter the existing code then press “ENTER” (Melody);

• Enter the“RELAY 1” operation time (2 digits 01 to 99 I.E. 05=5 seconds, 00= remain open time) or re-enter the existing time then

press “ENTER” (Melody);

• Enter the code (4 to 8 digits) to enable “RELAY 2” or re-enter the existing code then press “ENTER” (Melody);

• Enter the“RELAY 2” operation time (2 digits 01 to 99 I.E. 05=5 seconds, 00= remain open time) or re-enter the existing time then

press “ENTER” (Melody);

• Enter the code (4 to 8 digits) to enable “RELAY 3” or re-enter the existing code then press “ENTER” (Melody);

• Enter the“RELAY 3” operation time (2 digits 01 to 99 I.E. 05=5 seconds, 00= remain open time) or re-enter the existing time then

press “ENTER” (Melody);

• The system is ready to use (the red LED will be o).

PROGRAMMING NOTES

• After pressing enter following a command, press “ENTER” a further twice to exit the programming menu.

RETURN SYSTEM TO PRESET ENGINEER’S FACTORY CODE

• Turn o power to code lock;

• Keep “ENTER” button pressed while turning the power back on;

• Release “ENTER” button;

• The engineer’s code is now set to “111111” (six times one).

OPERATION

• Type in the programmed code and press “ENTER”;

• If the code is correct, the green LED will illuminate for ap-

prox. 2 seconds and the relay relevant to the code will oper-

ate for the programmed time;

• If a wrong code is entered, a continuous melody will sound

for 4 or more seconds, according to the number of mistakes;

• To switch o any relay while operating, type in the relevant

code then press the “CLEAR” button;

OPERATION NOTES

• To operate relays together, set the same code for each relay;

• If a wrong code is entered, the system will lock out for 5 sec-

onds which will increase each time a wrong code is entered.

The system will operate only when the correct code is entered.

TERMINALS:

SW2 Relay 2 command signal (active low)

SW1 Relay 1 command signal (active low)

NC3 Relay 3 normally closed contact

Max

24Vac/dc

3A

NO3 Relay 3 normally open contact

C3 Relay 3 common contact

NC2 Relay 2 normally closed contact

NO2 Relay 2 normally open contact

C2 Relay 2 common contact

NC1 Relay 1 normally closed contact

NO1 Relay 1 normally open contact

C1 Relay 1 common contact

12/24Vac/dc power input

+

Art.4800 - 4800M Digital codelock module