INSTALLATION

NOTES

Do not install any bulb sprinkler if the

bulb is cracked or there is a loss of

liquid from the bulb. With the sprin-

kler held horizontal, a small air bub-

ble should be present. The diameter of

the air bubble is approximately 1/16

inch (1,6 mm) for the 135°F/57°C to

3/32 inch (2,4 mm) for the

286°F/141°C temperature rating.

A leak tight 1/2 inch NPT sprinkler

joint should be obtained with a torque

of 7 to 14 ft.lbs. (9,5 to 19,0 Nm). A

maximum of 21 ft. lbs. (28,5 Nm) of

torque may be used to install sprin-

klers with 1/2 NPT connections. A

leak tight 3/4 inch NPT sprinkler

joint should be obtained with a torque

of 10 to 20 ft.lbs. (13,4 to 26,8 Nm). A

maximum of 30 ft. lbs. (40,7 Nm) of

torque may be used with 3/4 inch

NPT connections. Higher levels of

torque may distort the sprinkler inlet

with consequent leakage or impair-

ment of the sprinkler.

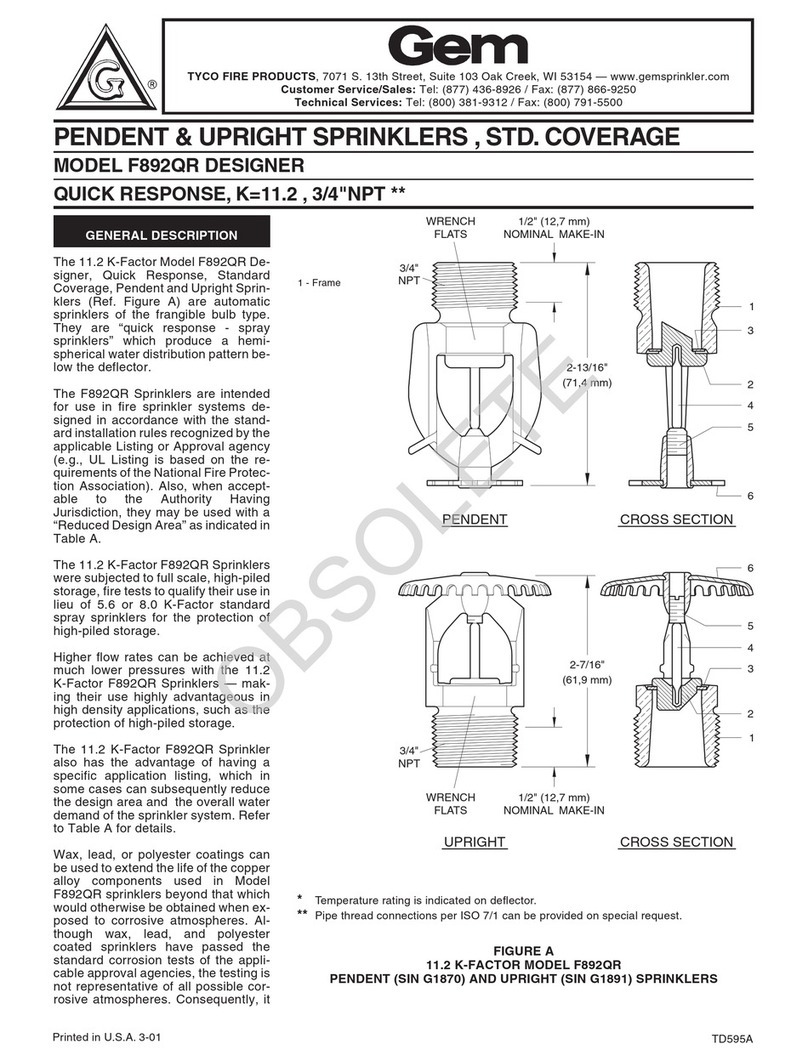

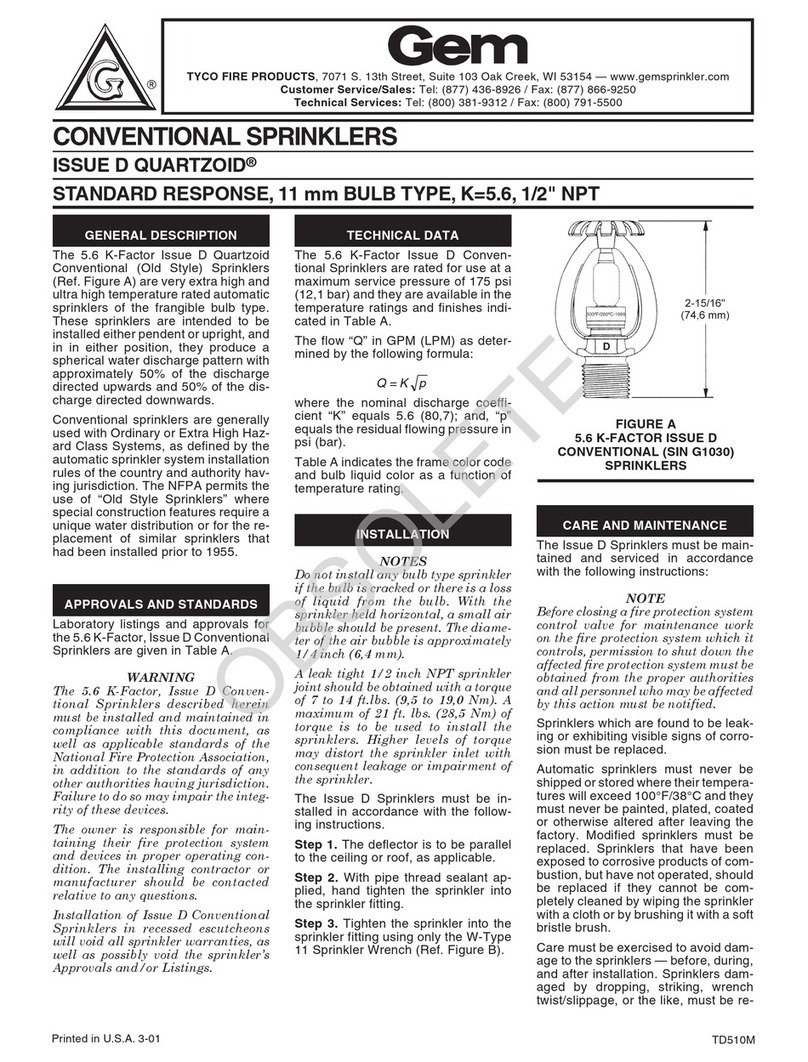

— Upright Sprinklers —

The Model A Intermediate Level Up-

right Sprinklers must be installed in

accordance with the following instruc-

tions.

Step 1. With pipe thread sealant ap-

plied to the pipe threads, hand tighten

the sprinkler into the sprinkler fitting.

Step 2. Tighten the sprinkler into the

sprinkler fitting using only the W-Type

6 Sprinkler Wrench (Ref. Figure B).

With reference to Figure A, the W-

Type 6 Sprinkler Wrench is to be ap-

plied to the wrench flats.

— Pendent Sprinklers —

The Model A Intermediate Level Pen-

dent Sprinklers must be installed in

accordance with the following instruc-

tions.

Step 1. Thread the Q-67 Shield onto

the sprinkler threads with the stamped

markings toward the deflector and just

to the end of the threads. The final

assembly step is easier to accomplish

if the Shield is not disengaged by con-

tinuing to turn the Shield past the

threads.

Step 2. Roll the O-Ring over the sprin-

kler threads until it seats against the

Shield.

Step 3. With pipe thread sealant ap-

plied to the pipe threads, hand tighten

the sprinkler into the sprinkler fitting.

Step 4. Tighten the sprinkler into the

sprinkler fitting using only the W-Type

6 Sprinkler Wrench (Ref. Figure B).

With reference to Figure A, the W-

Type 6 Sprinkler Wrench is to be ap-

plied to the wrench flats.

Step 5. Rotate the Q-67 Shield clock-

wise (looking up) so that it slightly

compresses the O-Ring between the

Shield and sprinkler fitting.

CARE AND MAINTENANCE

The Model A Sprinklers must be main-

tained and serviced in accordance

with the following instructions:

NOTE

Before closing a fire protection system

control valve for maintenance work

on the fire protection system which it

controls, permission to shut down the

affected fire protection system must be

obtained from the proper authorities

and all personnel who may be affected

by this action must be notified.

Sprinklers which are found to be leak-

ing or exhibiting visible signs of corro-

sion must be replaced.

Automatic sprinklers must never be

shipped or stored where their tempera-

tures will exceed 100°F/38°C and they

must never be painted, plated, coated

or otherwise altered after leaving the

factory. Modified sprinklers must be

replaced. Sprinklers that have been

exposed to corrosive products of com-

bustion, but have not operated, should

be replaced if they cannot be com-

pletely cleaned by wiping the sprinkler

with a cloth or by brushing it with a soft

bristle brush.

Care must be exercised to avoid dam-

age to the sprinklers — before, during,

and after installation. Sprinklers dam-

aged by dropping, striking, wrench

twist/slippage, or the like, must be re-

placed. Also, replace any sprinkler that

has a cracked bulb or that has lost

liquid from its bulb (ref. Installation

Section Note).

Frequent visual inspections are rec-

ommended to be initially performed for

lead coated sprinklers, after the instal-

lation has been completed, to verify

the long term potential integrity of the

sprinkler coatings. Thereafter, annual

inspections per NFPA 25 should suf-

fice; however, instead of inspecting

from the floor level, a random sampling

of close-up visual inspections should

be made, so as to better determine the

exact sprinkler condition and the long

term integrity of the lead coating, as it

may be affected by the corrosive con-

ditions present.

The owner is responsible for the in-

spection, testing, and maintenance of

their fire protection system and de-

vices in compliance with this docu-

ment, as well as with the applicable

standards of the National Fire Protec-

tion Association (e.g., NFPA 25), in

addition to the standards of any other

authorities having jurisdiction. The in-

stalling contractor or sprinkler manu-

facturer should be contacted relative

to any questions.

It is recommended that automatic

sprinkler systems be inspected,

tested, and maintained by a qualified

Inspection Service.

LIMITED WARRANTY

Products manufactured by Tyco Fire

Products are warranted solely to the

original Buyer for ten (10) years

against defects in material and work-

manship when paid for and properly

installed and maintained under normal

use and service. This warranty will ex-

pire ten (10) years from date of ship-

ment by Tyco Fire Products. No war-

ranty is given for products or

components manufactured by compa-

nies not affiliated by ownership with

Tyco Fire Products or for products and

components which have been subject

to misuse, improper installation, corro-

sion, or which have not been installed,

maintained, modified or repaired in ac-

cordance with applicable Standards of

the National Fire Protection Associa-

tion, and/or the standards of any other

Authorities Having Jurisdiction. Mate-

rials found by Tyco Fire Products to be

defective shall be either repaired or

replaced, at Tyco Fire Products’ sole

option. Tyco Fire Products neither as-

sumes, nor authorizes any person to

assume for it, any other obligation in

connection with the sale of products or

parts of products. Tyco Fire Products

shall not be responsible for sprinkler

system design errors or inaccurate or

incomplete information supplied by

Buyer or Buyer’s representatives.

IN NO EVENT SHALL TYCO FIRE

PRODUCTS BE LIABLE, IN CON-

TRACT, TORT, STRICT LIABILITY

OR UNDER ANY OTHER LEGAL

THEORY, FOR INCIDENTAL, INDI-

RECT, SPECIAL OR CONSEQUEN-

TIAL DAMAGES, INCLUDING BUT

NOT LIMITED TO LABOR CHARGES,

REGARDLESS OF WHETHER TYCO

FIRE PRODUCTS WAS INFORMED

ABOUT THE POSSIBILITY OF SUCH

DAMAGES, AND IN NO EVENT

SHALL TYCO FIRE PRODUCTS’ LI-

ABILITY EXCEED AN AMOUNT

EQUAL TO THE SALES PRICE.

THE FOREGOING WARRANTY IS

MADE IN LIEU OF ANY AND ALL

OTHER WARRANTIES EXPRESS

OR IMPLIED, INCLUDING WARRAN-

TIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PUR-

POSE.