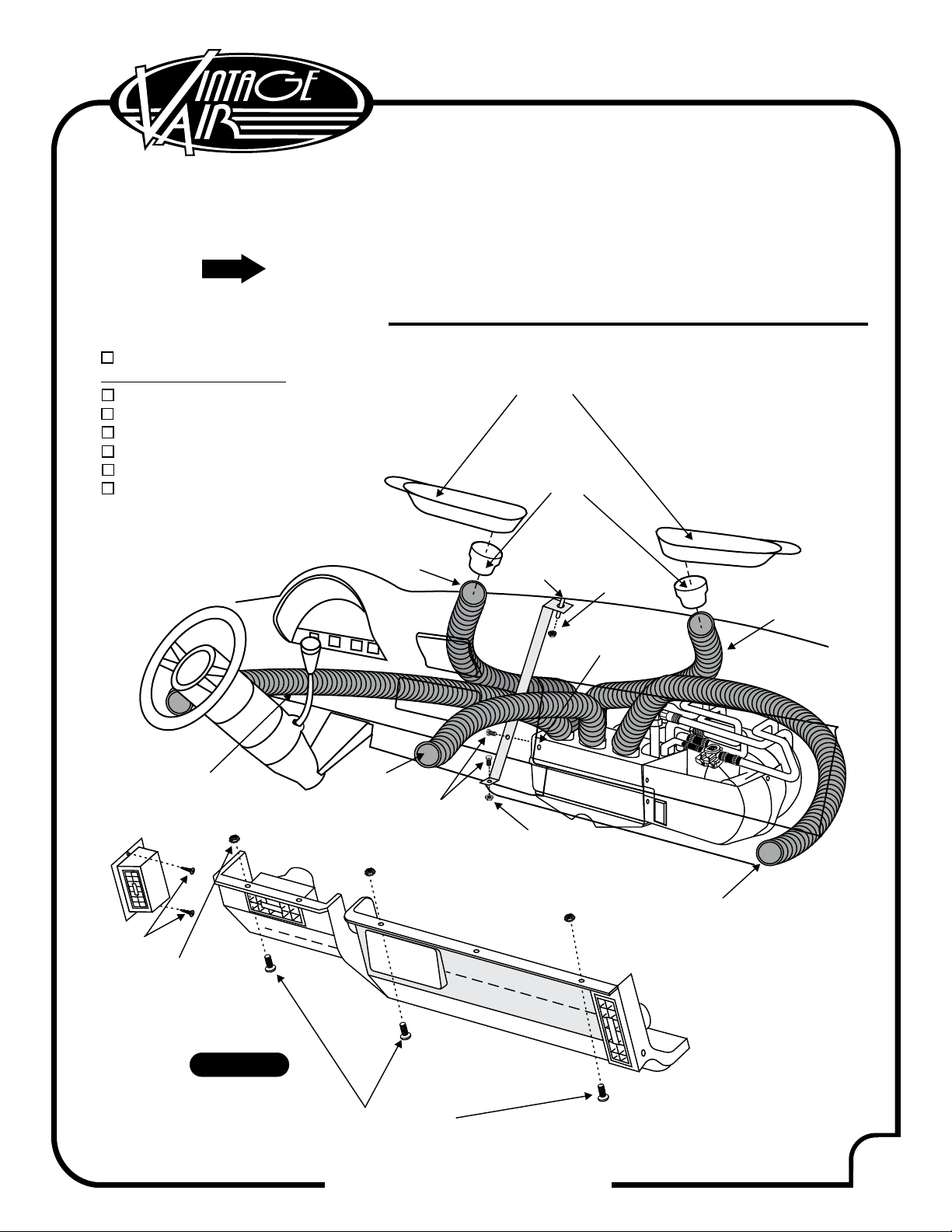

1. PLACE EVAPORATOR UNDER DASH ON PASSENGER SIDE WITH THE FEEDER TUBE OUTLETS POINTED TOWARD THE FIREWALL.

2. INSTALL BINARY SAFETY SWITCH AS SHOWN ON PAGE 11.

3. POSITION THE EVAPORATOR BEHIND DASH BY TILTING THE UNIT APPROXIMATELY 45° TOWARD YOURSELF, WITH THE TUBES FACING THE FIREWALL.

ROTATE THE EVAPORATOR AWAY FROM YOU, SO THAT THE TUBE OPENINGS ARE POINTING INTO THE ENGINE COMPARTMENT THROUGH THE O.E.M.

HEATER MOTOR OPENING IN THE FIREWALL.

4. ATTACH THE BLOWER HOUSING BRACKET TO THE FIREWALL USING THE O.E.M. HOLE AND A 1/4”-20 x 1/2” BOLT AND NUT, AND 2 FLAT WASHERS AS

SHOWN IN FIGURE 12, PAGE 14.

5. ATTACH THE TOP EVAPORATOR BRACKET TO THE COWL VENT FLANGE BY USING TWO #8 x 1/2" SCREWS IN THE PREVIOUSLY DRILLED HOLES.

BOLT TO THE CASE WITH 2 EACH 1/4”-20 x 1/2” BOLTS, AS SHOWN IN FIGURE 11, PAGE 13.

6. ATTACH FRONT EVAPORATOR BRACKET TO EVAPORATOR CASE AND BOTTOM OF DASH USING (2) 1/4”-20 x 1/2” BOLTS AND NUTS, AS SHOWN IN

FIGURE 1, PAGE 5.

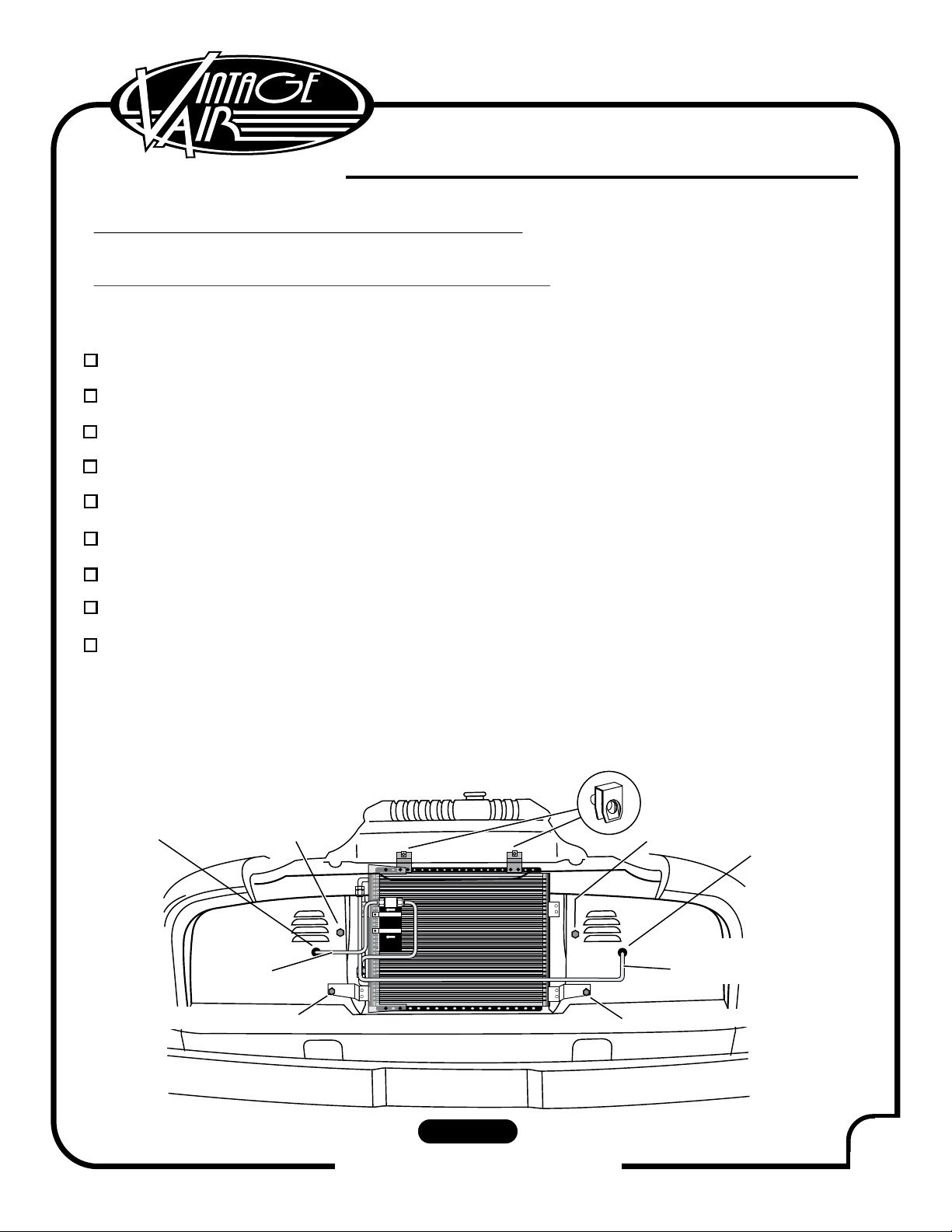

1. INSTALL FIREWALL COVER & GROMMETS OVER EVAPORATOR FEEDER TUBES (AS SHOWN IN FIGURE 7A, PAGE 11) AND BOLT TO FIREWALL AS SHOWN

IN FIGURE 12, PAGE 14.

2. LOCATE THE #10 A/C SUCTION HOSE. TEMPORARILY CONNECT (NO O’RING NEEDED AT THIS TIME) THE CRIMPED END OF THIS HOSE TO THE

#10 EVAPORATOR FEEDER TUBE AND ROUTE THE UNCRIMPED END TO THE COMPRESSOR.

TEMPORARILY INSTALL THE #10-90° FITTING (IN BAG) TO THE COMPRESSOR. (NOTE: THIS IS A TEMPORARY CONNECTION WHICH DOES NOT

REQUIRE AN O-RING AT THIS TIME). HAND TIGHTEN THE FITTINGS.

3. ROUTE THE #10 HOSE TO THE #10 FITTING ON THE COMPRESSOR AND CUT TO LENGTH. (NOTE: MAKE SURE THE A/C BELT IS PROPERLY TENSIONED

BEFORE CUTTING HOSES TO LENGTH). PUSH THIS #10 HOSE ONTO THE FITTING AND LEAVE TEMPORARILY.

4. LOCATE THE #6 A/C HOSE. TEMPORARILY CONNECT THE CRIMPED END OF THIS HOSE TO THE #6 EVAPORATOR FEEDER TUBE. ROUTE THE

UNCRIMPED END OF THIS HOSE TO THE #6 ALUMINUM HARDLINE WHICH PASSES THROUGH THE PASSENGER SIDE OF THE CORE SUPPORT.

TEMPORARILY CONNECT THE #6 - 90° FITTING (IN BAG) TO THE #6 ALUMINUM HARDLINE WHICH PASSES THROUGH THE CORE SUPPORT.

5. ROUTE THE #6 HOSE TO THE #6 FITTING AND CUT TO LENGTH. (LEAVE THE #6 HOSE CONNECTED TO THIS FITTING, TEMPORARILY).

6. LOCATE THE #8 DISCHARGE HOSE.

7. TEMPORARILY CONNECT (NO O-RINGS) THE CRIMPED END OF THIS HOSE TO THE #8 DISCHARGE HARDLINE WHICH IS CONNECTED TO THE TOP

PORT ON THE CONDENSER, AND PASSES THROUGH THE CORE SUPPORT.

8. ROUTE THE #8 DISCHARGE HOSE TO THE COMPRESSOR.

9. TEMPORARILY CONNECT THE #8 FITTING (IN BAG) TO THE COMPRESSOR.

10. ROUTE THE #8 DISCHARGE HOSE TO THE FITTING AND CUT HOSE TO LENGTH. PUSH #8 A/C HOSE ONTO THE #8 FITTING.

(NOTE: MAKE SURE THE A/C BELT IS PROPERLY TENSIONED BEFORE CUTTING HOSES TO LENGTH).

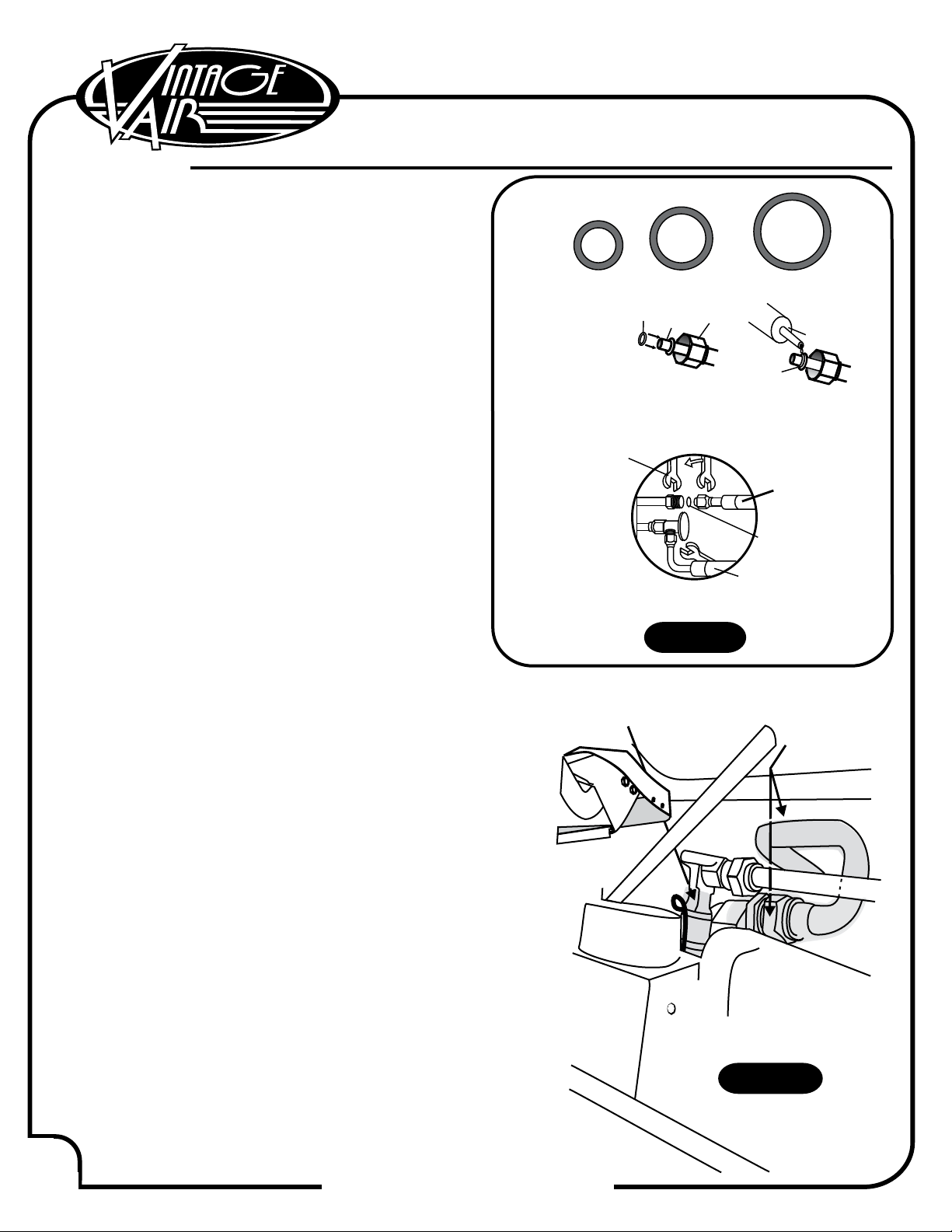

11. REMOVE THE #6, #8 & #10 HOSES. FOLLOW THE CRIMPING INSTRUCTIONS SUPPLIED WITH YOUR HOSE KIT AND CRIMP ALL HOSE CONNECTIONS.

REINSTALL ALL HOSES USING O-RINGS FOR THE FINAL CONNECTION. (BE SURE TO LUBRICATE O-RINGS AND TIGHTEN PROPERLY. SEE FIGURE 5,

PAGE 10). RE

INST

ALL ALL THE A/C HOSES. WRAP THE METAL PORTIONS OF THE #10 FITTING WITH SUPPLIED PRESS TAPE.

* NOTE: MARK POSITION OF HOSES/FITTINGS (CLOCKING) PRIOR TO CRIMPING. AFTER HOSES ARE CRIMPED, THEY WILL NOT

ROTATE INSIDE FITTING.

* NOTE: BULK HEATER HOSE NOT SUPPLIED WITH KIT. OBTAIN 5/8" HEATER HOSE FROM LOCAL AUTO PARTS RETAILER.

1. CONNECT A LENGTH OF 5/8” HEATER HOSE TO THE TOP PASSENGER SIDE HEATER HOSE FEEDER LINE AT THE FIREWALL COVER (THE TOP

PASSENGER SIDE FEEDER LINE CONTAINS THE HEATER CONTROL VALVE). ROUTE THIS HOSE TO THE HEATER HOSE PRESSURE PORT (THIS IS

USUALLY FROM THE INTAKE MANIFOLD). CUT TO LENGTH AND CONNECT WITH A HOSE CLAMP (SEE FIGURE 12, PAGE 14).

2. CONNECT A LENGTH OF 5/8” HEATER HOSE TO THE TOP DRIVER SIDE HEATER HOSE FEEDER LINE AT THE FIREWALL COVER. ROUTE THIS HOSE TO

THE HEATER HOSE SUCTION PORT (USUALLY LOCATED ON THE WATER PUMP). CUT TO LENGTH AND CONNECT WITH A HOSE CLAMP

(SEE FIGURE 12, PAGE 14).

EVAPORATOR INSTALLATION

REFRIGERATION HOSES

HEATER HOSES

9

1956 F-100 FORD TRUCK w/ H/C/D

905456-LFZ-A REV E 03/05/14, 56 FORD PICK UP INSTRUCTIONS PG 9 OF 19