3

904107 REV C 4/13/15, INST 69 FIREBIRD w/o AC CNTRL PNL PG 3 OF 17

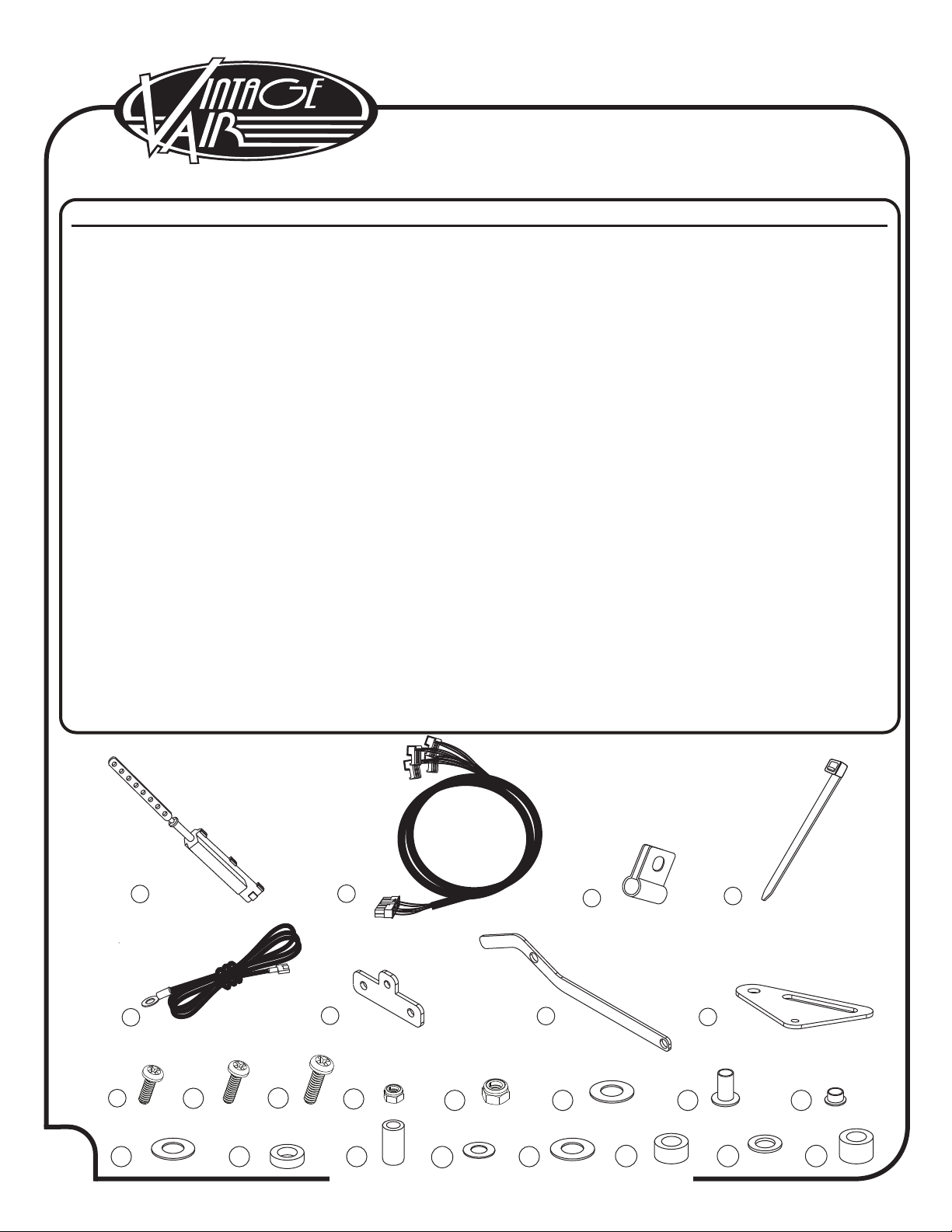

No. Qty. Part No. Description

Packing List: 1969 Firebird

Control Panel Conversion Kit (474164)

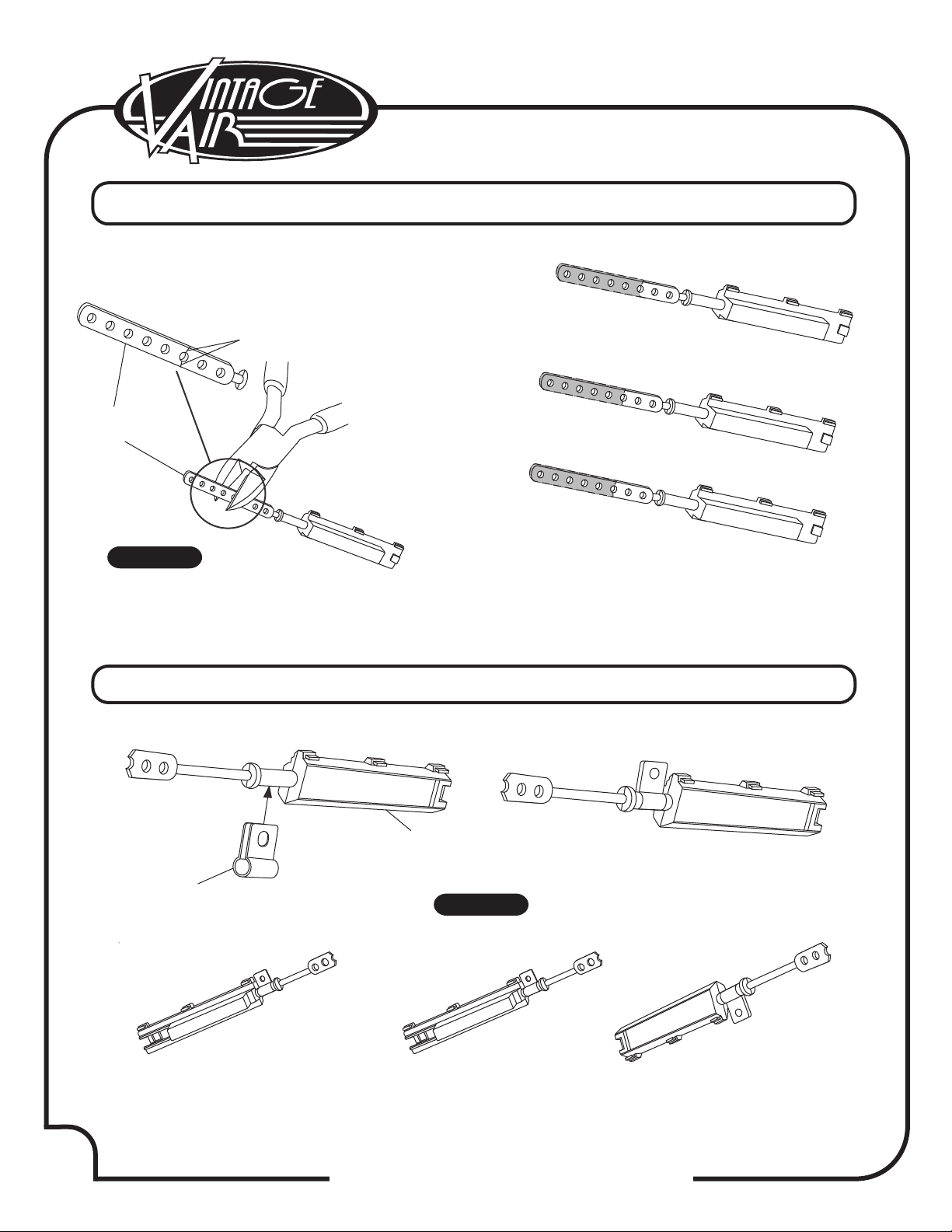

Slide Pot Assembly

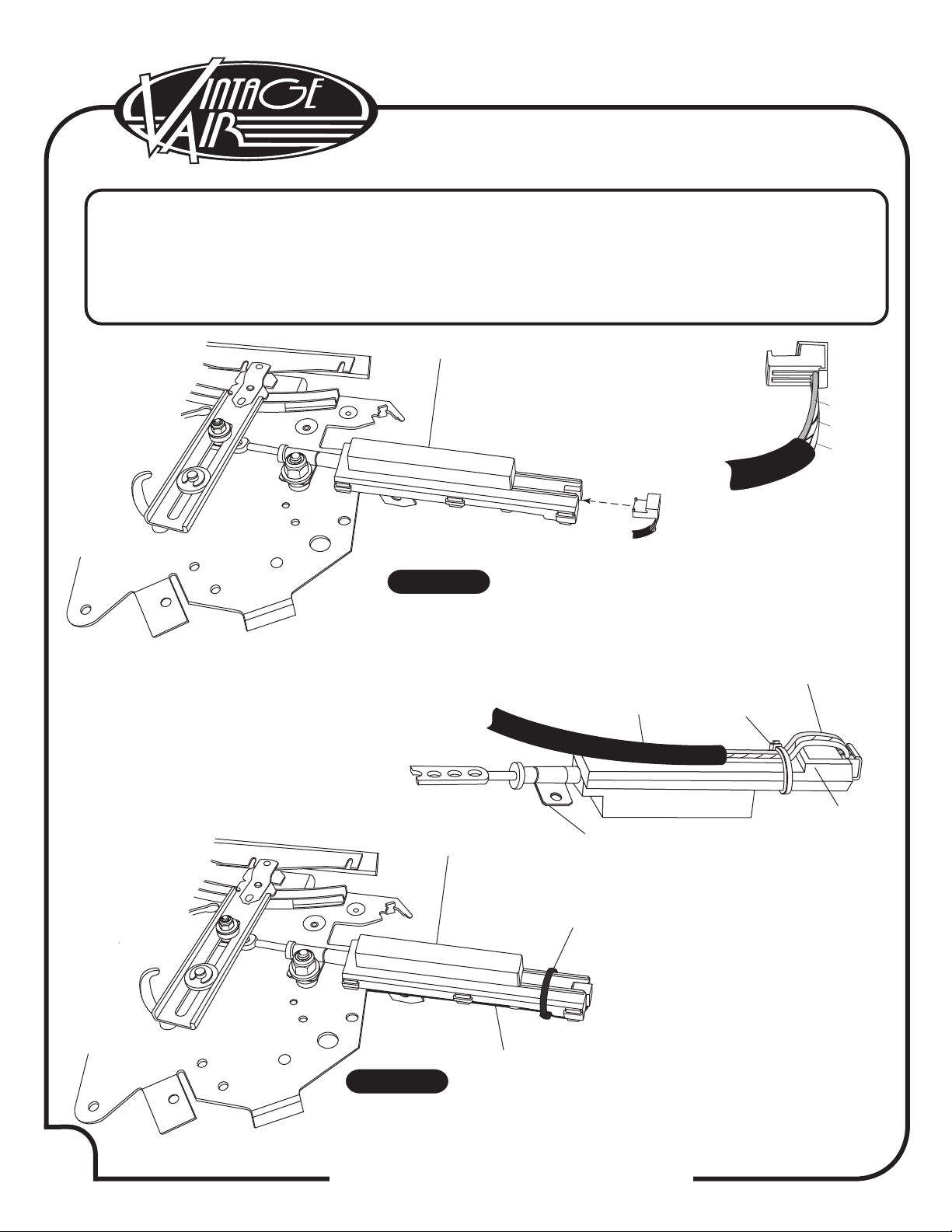

Gen IV Universal Control Harness

Slide Pot Clamp

4” Tie Wrap

Ground Wire

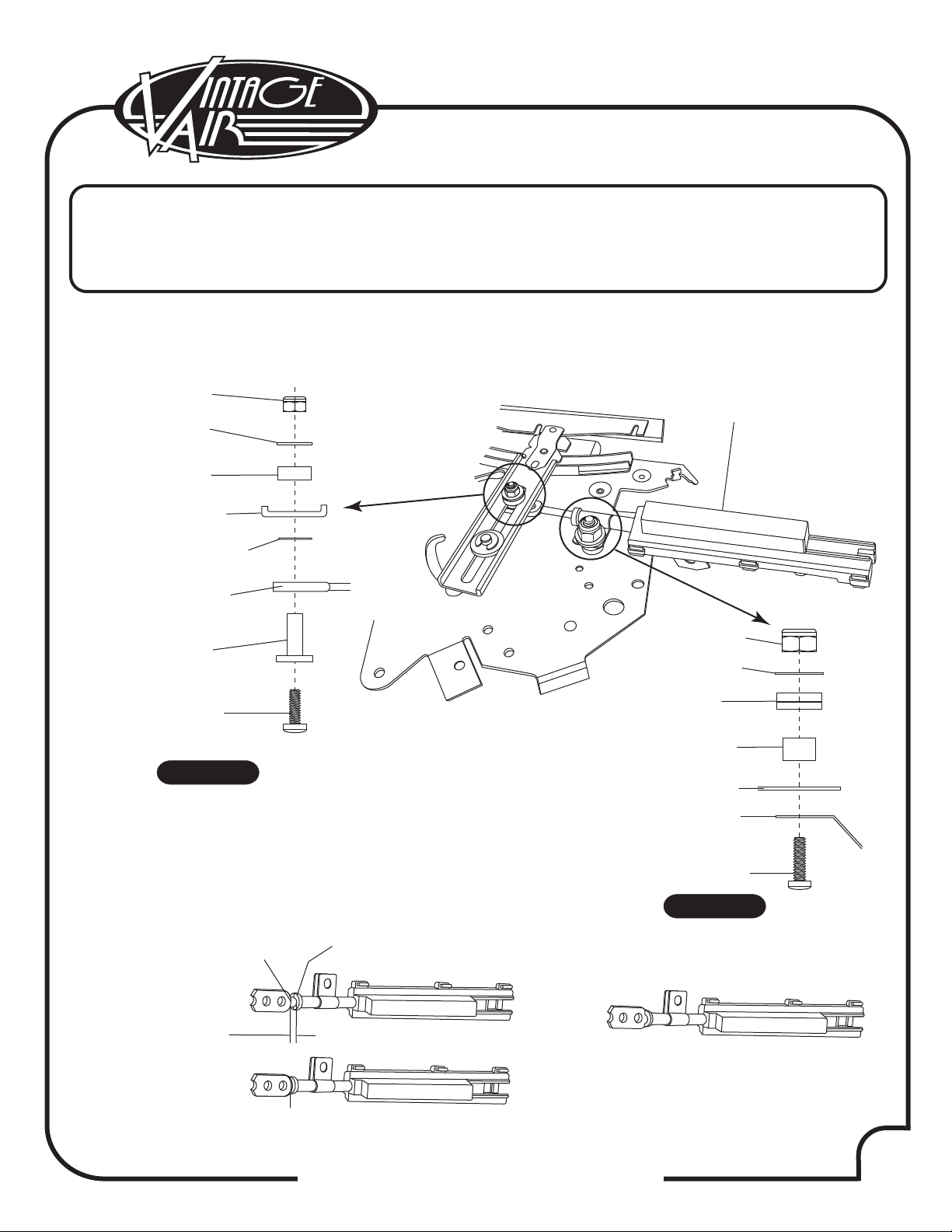

69 Firebird Blower Switch Pivot Bracket

69 Firebird Blower Switch Lever

69 Firebird wo A/C Heat/Cool Control Bracket

4-40 X 3/8” PH Pan Head Screw

4-40 X 5/8” PH Pan Head Screw

8-32 X 3/4” PH Pan Head Screw

4-40 Nyloc Nut

8-32 Nyloc Nut

#8 Flat Washer

1/8” Nylon Insert

Nylon Bushing

1/16” Nylon Flat Washer

1/8” Nylon Flat Washer

.128 ID/.198 ID x.313 OD x.375 L Nylon Spacer

SAE Flat Washer 3/16” X .500

1/16” Nylon Spacer/ Washer

.166 ID x .375 OD x .250 L Nylon Flat Washer

.140 ID x .250 OD x .065 L Nylon Flat Washer

.188 ID x .375 OD x .188 L Nylon Flat Washer

112002-SUA

232002-VUA

491010-VUR

21301-VUP

231520

644014

644015

644016

18413-VUB

18400-VUB

18113-PSR

18412-VUB

18602-NSR

18657-JSS

49700-VUI

49701-VUI

49704-VUI

49705-VUI

180041-SSR

18123-VUB

186009-WSR

180385

180383

180384

3

1

3

5

1

1

1

1

3

3

2

6

2

4

3

1

3

3

1

3

1

1

2

1

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

** Before beginning installation, open all packages and check contents of shipment.

Please report any shortages directly to Vintage Air within 15 days. After 15 days,

Vintage Air will not be responsible for missing or damaged items.

2

6

4

57

13

8

9 10 11 12 13 14 15 16

17 18 19 20 21 22 23 24