2

www.vintageair.com

905460 REV D 01/12/17, PG 2 OF 28

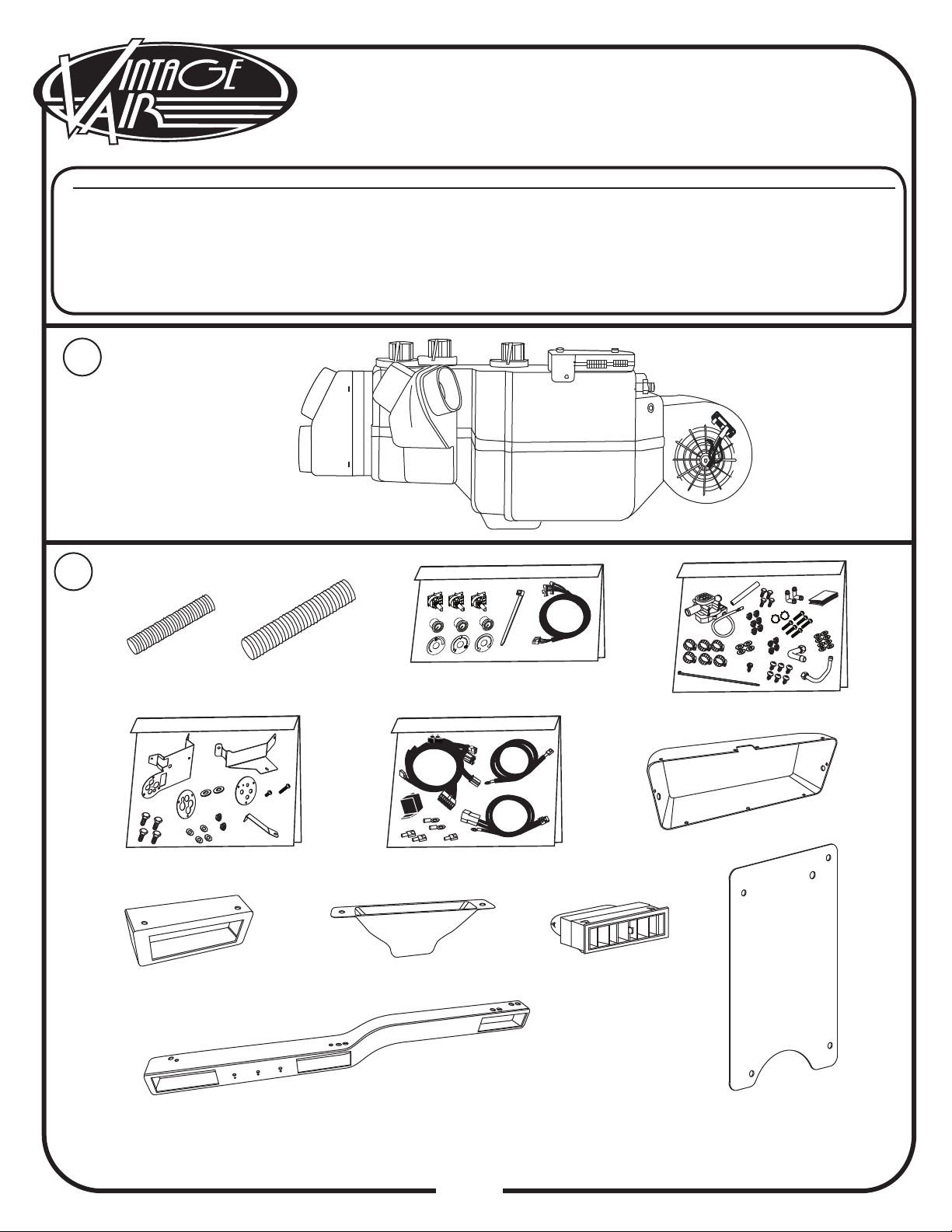

Thank you for purchasing this condenser kit from Vintage Air. When installing these

components as part of a complete SureFit™ system, Vintage Air recommends working

from front to back on the vehicle, installing the condenser kit and compressor rst,

followed by the evaporator, wiring and hoses, and control panel.

Cover..................................................................................................................................

Table of Contents.................................................................................................................

Packing List/Parts Disclaimer..................................................................................................

Information Page..................................................................................................................

Wiring Notice.......................................................................................................................

Engine & Passenger Compartment Disassembly........................................................................

Condenser Assembly and Installation, Compressor and Brackets, Pulleys, Defrost Duct

Installation..........................................................................................................................

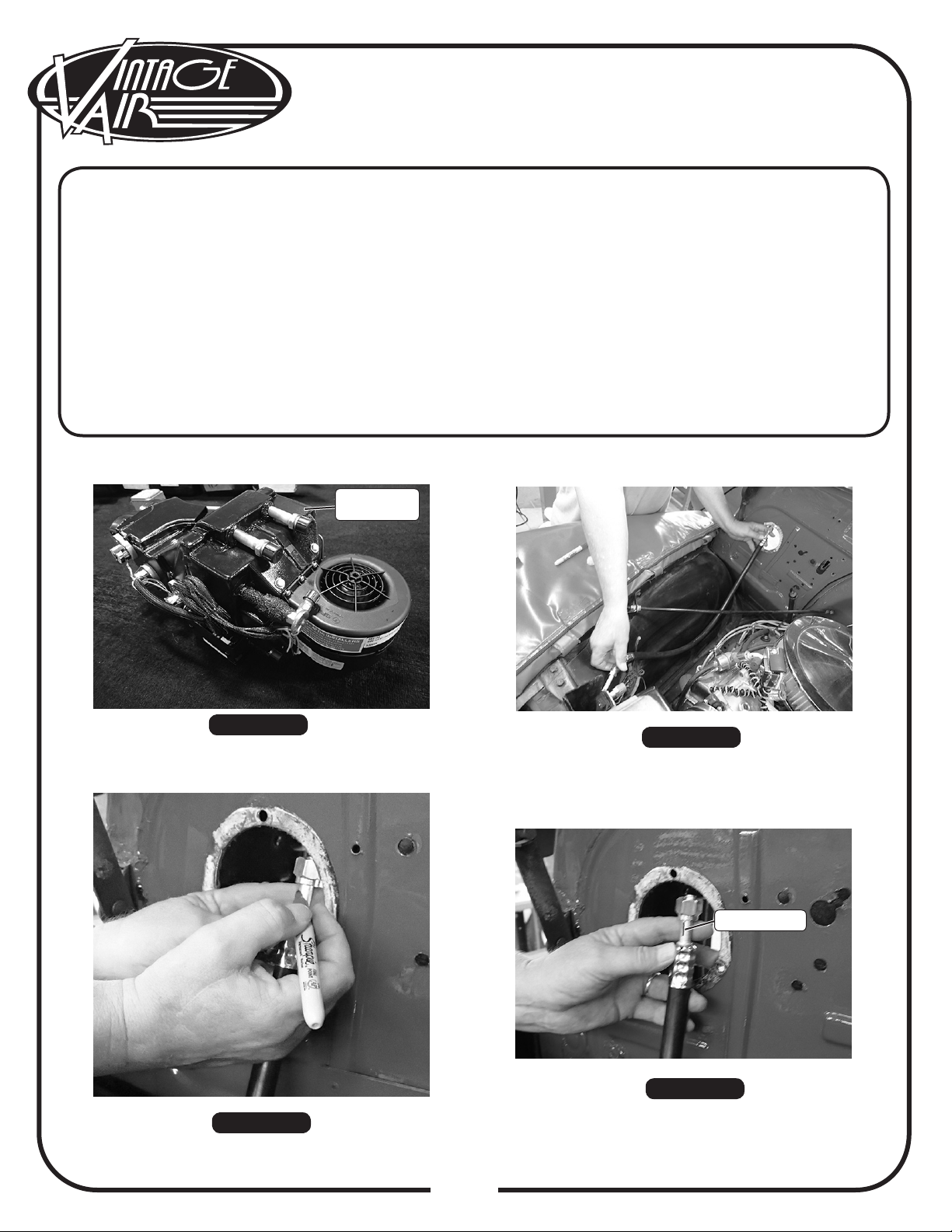

Evaporator Assembly Preparation...........................................................................................

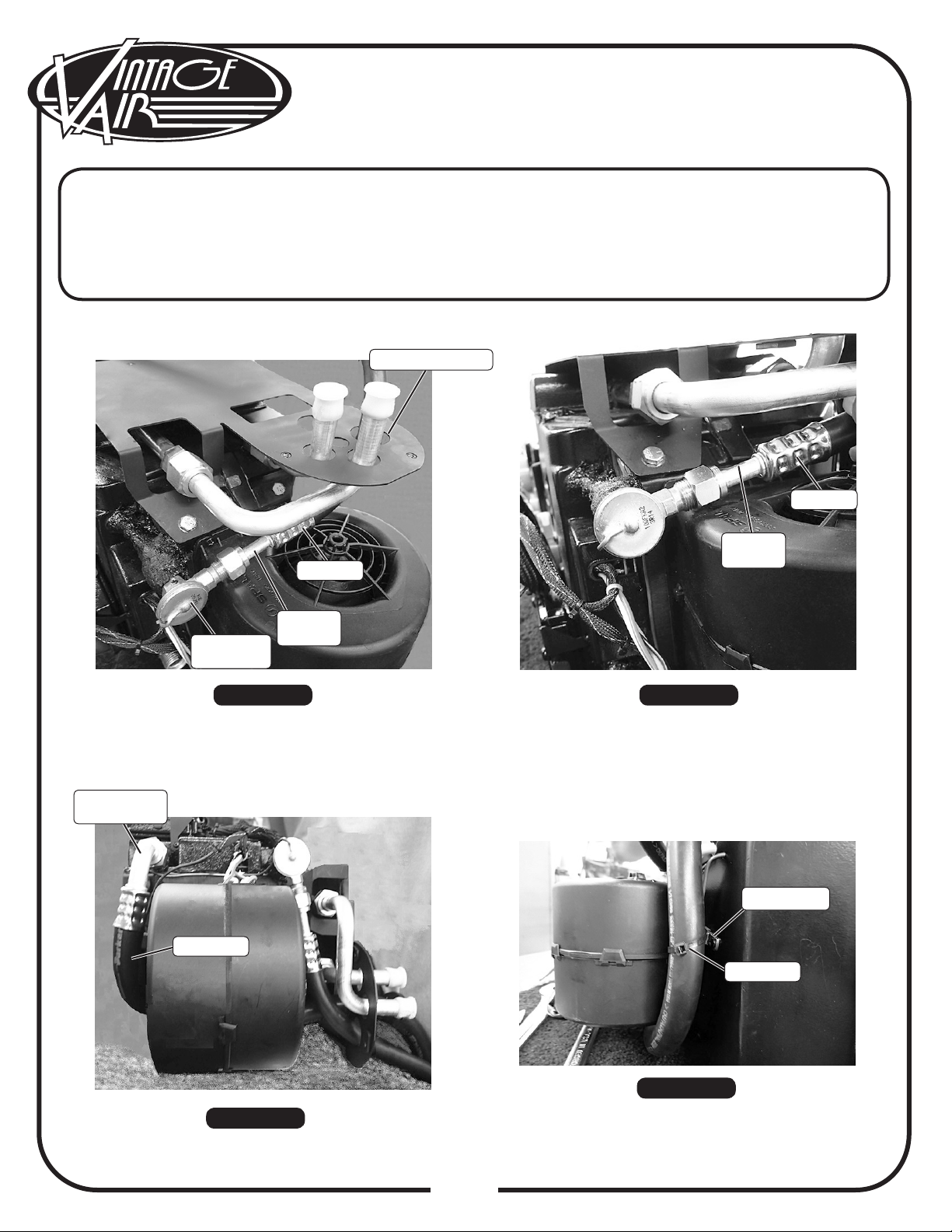

Firewall Bracket and Heater Hose Fitting Installation, Lubricating O-rings.....................................

A/C & Heater Hose Installation.............................................................................................

A/C & Heater Hose Installation (Cont.), Firewall Cover Installation............................................

Evaporator Installation........................................................................................................

Evaporator Installation (Cont.).............................................................................................

Rotary Pot Installation.........................................................................................................

Control Panel/Louver Bezel Assembly Installation....................................................................

Evaporator Installation (Final)..............................................................................................

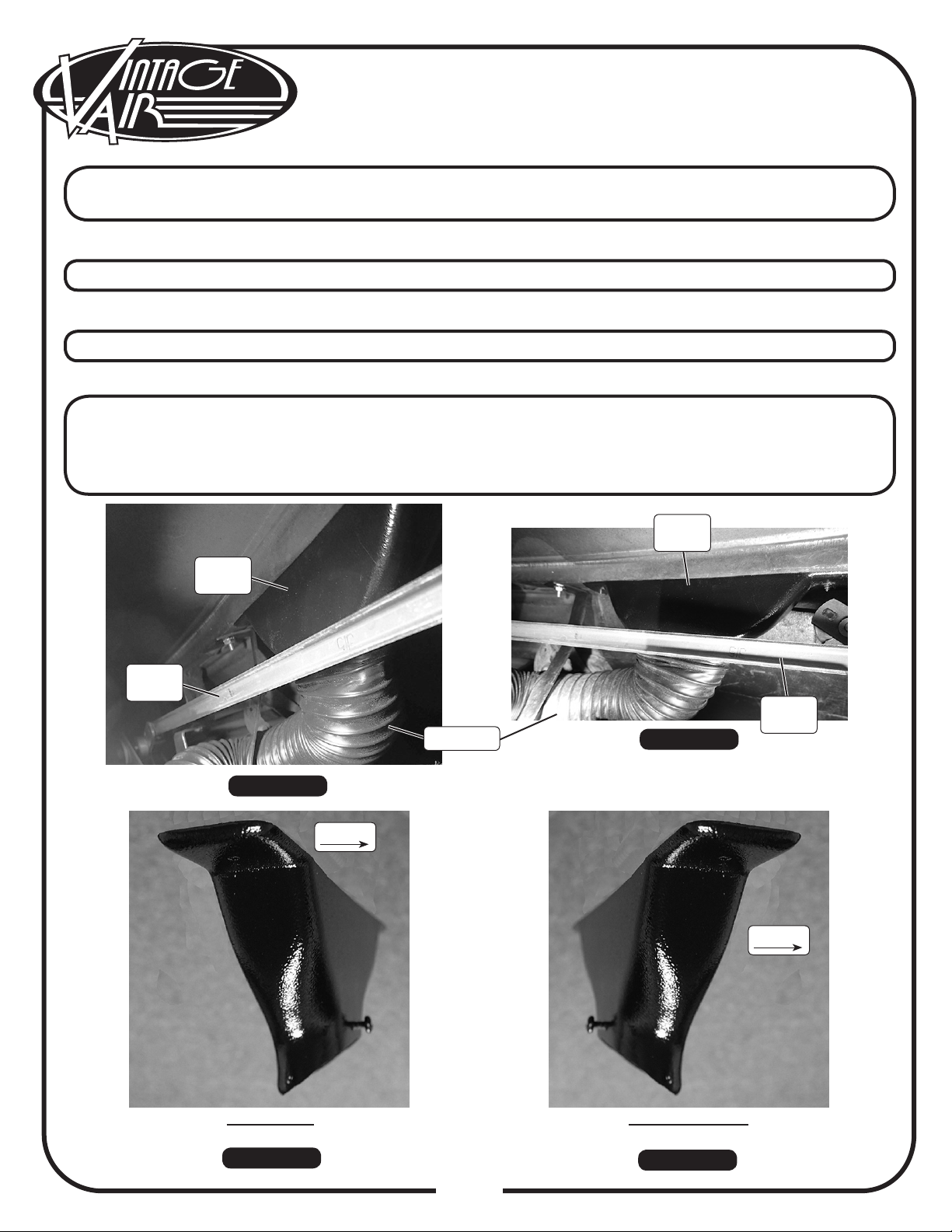

Driver Side Under Dash Louver Installation, Heater Control Valve Installation.............................

A/C & Heater Hose Installation, V-8 Engines (Final)................................................................

A/C & Heater Hose Installation, 6-Cylinder Engines (Final).......................................................

Control Panel & Duct Hose Routing.......................................................................................

Wiring, Glove Box Installation..............................................................................................

Drain Hose Installation, Final Steps......................................................................................

Wiring Diagram..................................................................................................................

Gen IV Wiring Connection Instruction....................................................................................

Operation of Controls..........................................................................................................

Troubleshooting Guide.........................................................................................................

Troubleshooting Guide (Cont.)..............................................................................................

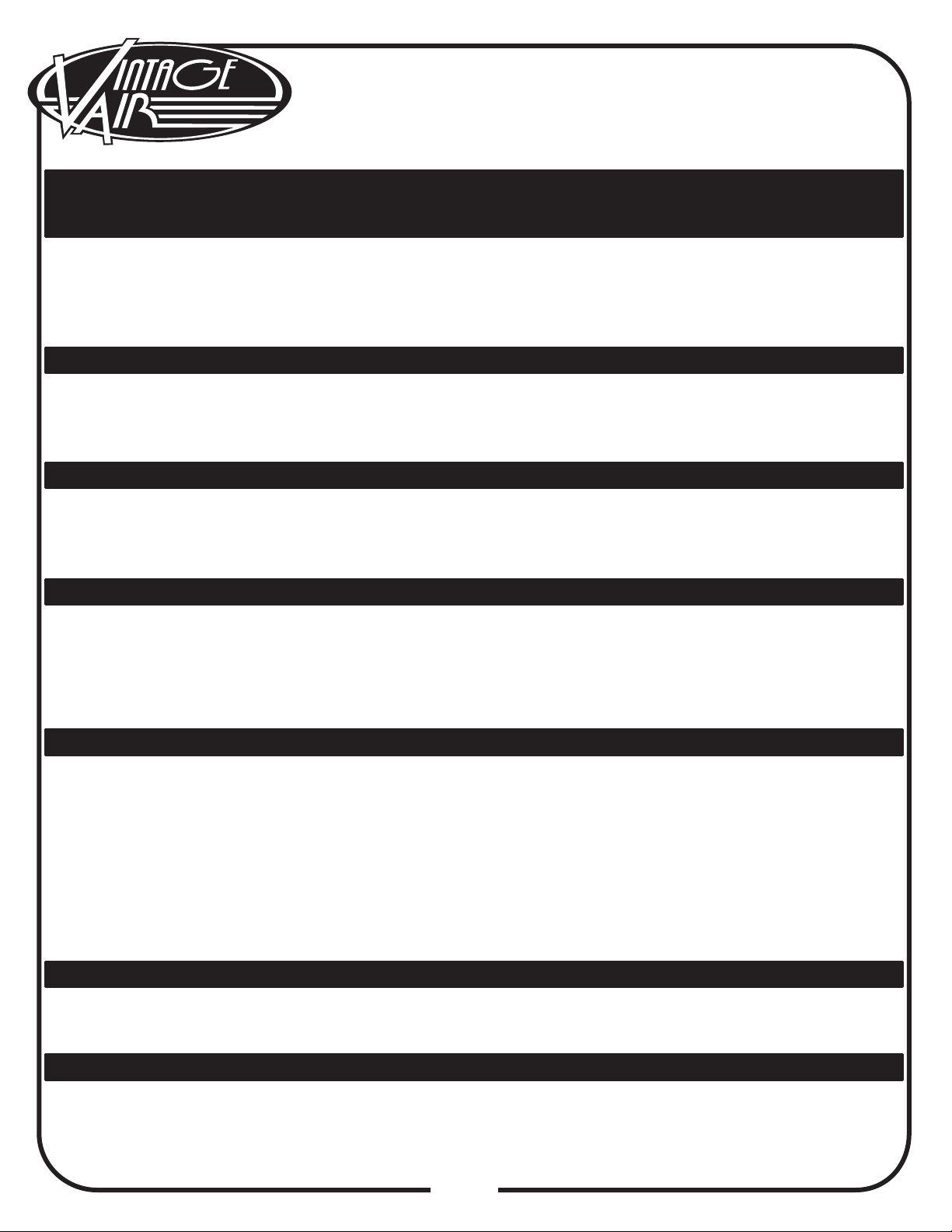

Packing List.......................................................................................................................

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

Table of Contents