NEVO+600 Series

AC/DC MODULAR CONFIGURABLE POWER SUPPLIES

User Manual

Page 4of 31

DOC-MN-005-03, NEVO+600 User Manual

Vox Power Limited | Unit 2, Red Cow Interchange Estate, Ballymount, Dublin 22, D22 Y8H2, Ireland | T +353 1 4591161 | www.vox-power.com

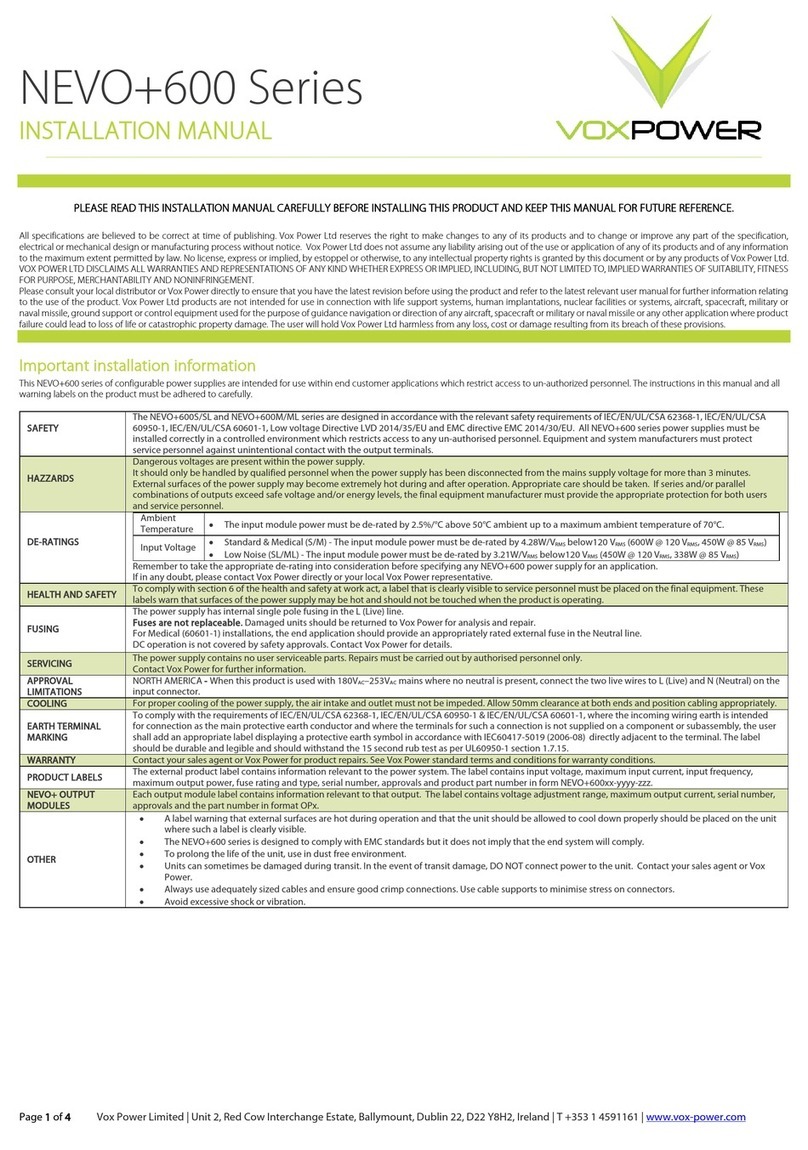

Installation Notes

This power supply is intended for use within equipment or enclosures which restricts access to authorised personnel only. The instructions in this manual

and all warning labels on the product must be followed carefully.

Safety

All power supplies must be installed correctly in a controlled environment which restricts access to any unauthorised personnel. Equipment and system

manufacturers must protect service personnel against unintentional contact with the output terminals.

Hazards

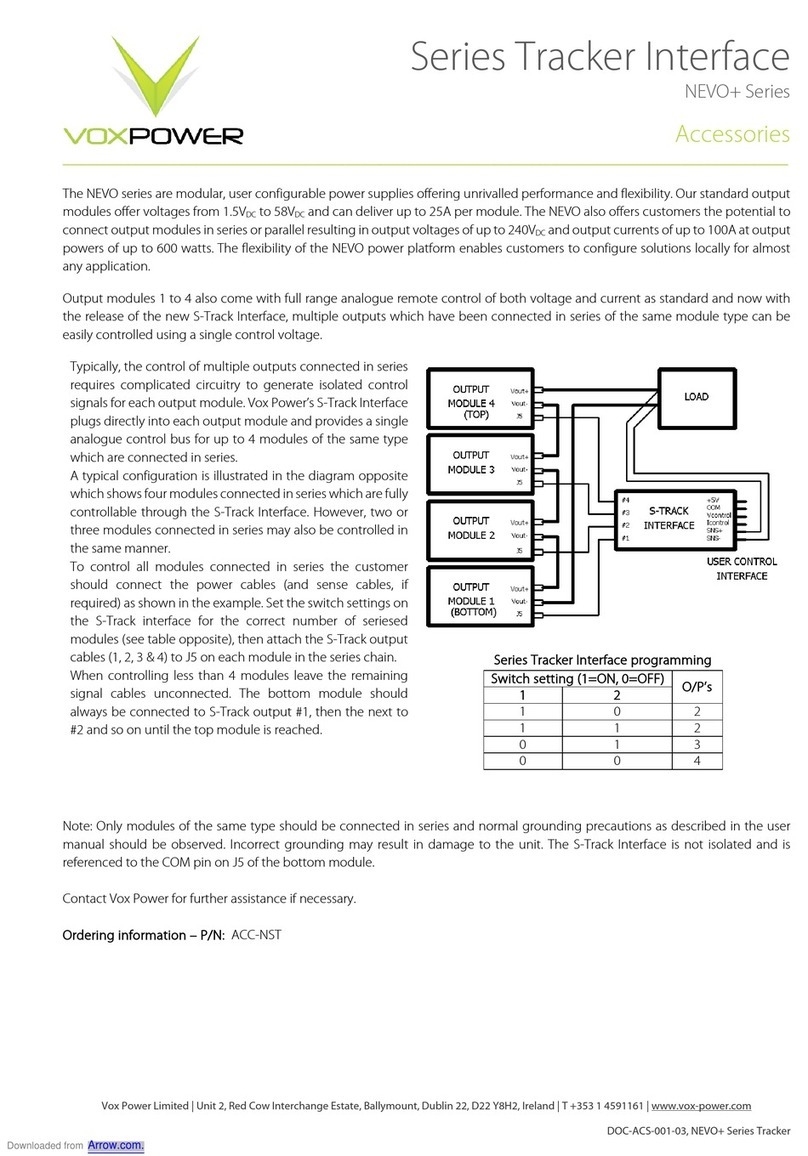

If series and/or parallel combinations of outputs exceed safe voltage and/or energy levels, the final equipment manufacturer must provide appropriate

protection for both users and service personnel.

Health and safety

To comply with section 6 of the health and safety at work act, a label that is clearly visible to service personnel must be placed on the final equipment,

which warns that surfaces of the power supply may be hot and should not be touched when the product is operating.

Fusing

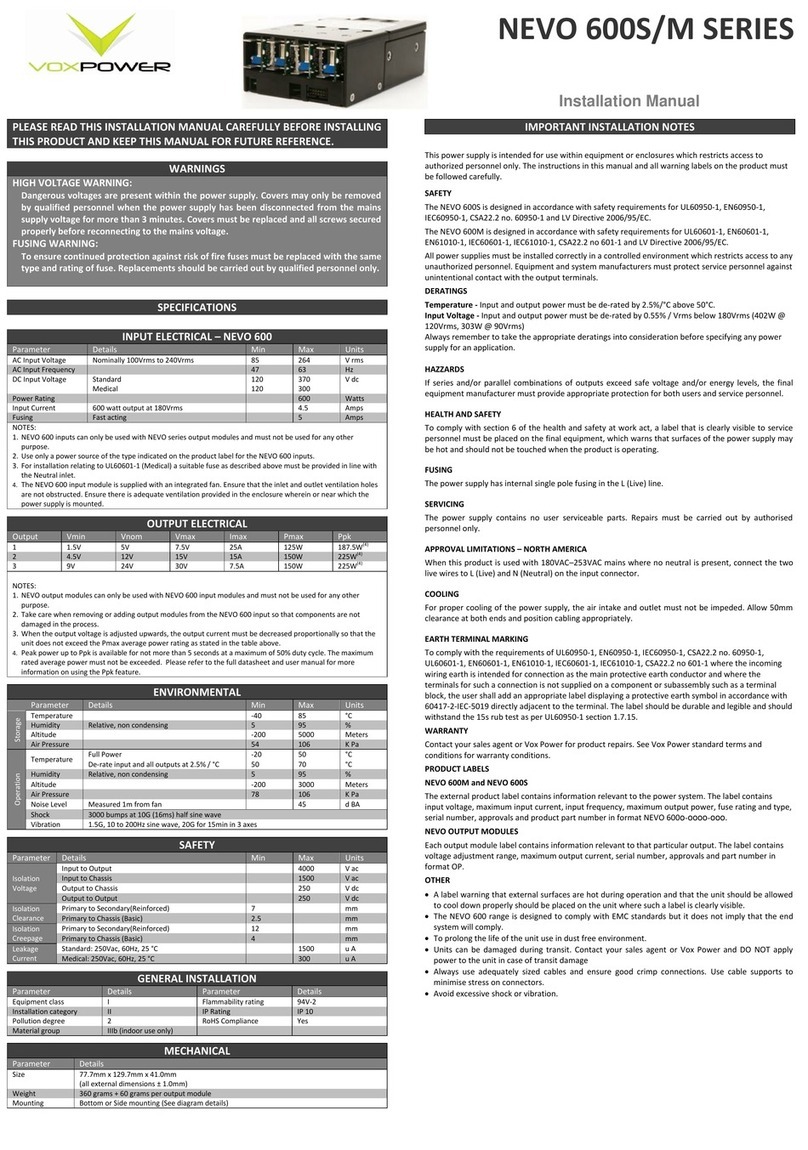

The power supply has internal single pole fusing in the L (Live) line.

Servicing

The power supply contains no user serviceable parts. Repairs must be carried out by authorised personnel only. Contact Vox Power Ltd for further

information.

Cooling

For proper cooling of the power supply, the air intake and outlet must not be impeded. Allow 50 mm clearance at both ends and position cabling

appropriately. Avoid excessive back pressure in the general system or when using ducting to navigate hot air out of the system.

Earth terminal marking

To comply with the requirements of UL60950-1, EN60950-1, IEC60950-1, CSA22.2 no. 60950-1, UL60601-1, EN60601-1, EN61010-1, IEC60601-1, IEC61010-1,

CSA22.2 no 601-1 where the incoming wiring earth is intended for connection as the main protective earthing conductor and where the terminals for such

a connection is not supplied on a component or subassembly such as a terminal block, the user shall add an appropriate label displaying a protective

earth symbol in accordance with 60417-2-IEC-5019 directly adjacent to the terminal. The label should be durable and legible and should withstand the 15s

rub test as per UL60950-1 section 1.7.15.

Mounting

The unit can be mounted using the bottom or side mounting points. Each mounting point accepts an M4 screw where the maximum penetration,

inclusive of 1.75 mm chassis thickness, should never exceed 4.00 mm. The maximum torque for the M4 screws is 0.55Nm.

Other

•To prolong the life of the unit, use in a dust free environment.

•If units are damaged during transit, contact your sales agent or Vox Power and DO NOT apply power to the unit.

•Always use adequately sized cables and ensure good crimp connections.

•Use cable supports to minimise stress on connectors.

•Avoid excessive shock or vibration.

General installation parameters

•Equipment class I

•Installation category II

•Pollution degree 2

•Material group IIIb (Indoor use only)

•Flammability rating 94V-2

•IP rating IP10

•RoHS compliance 2011/65/EU