4 | Page

VCCM600 Series User Manual | DOC6103r00 | Release date 02/03/2017

Vox Power Limited | Unit 2, Red Cow Interchange Estate, Ballymount, Dublin 22, D22 Y8H2, Ireland | T +353 1 4591161 | www.vox-power.com

Important installation information

The VCCM600 series of configurable power supplies are intended for use within end customer applications which restrict access to un-authorized personnel. The

instructions in this manual and all warning labels on the product must be adhered to carefully.

SAFETY

The VCCM600S and VCCM600M series are designed in accordance with the relevant safety requirements of UL60950-1, IEC/EN60950-1, UL60601-1, IEC/EN60601-

1, CSA22.2 no 601-1, Low voltage Directive LVD 2014/35/EU and EMC directive EMC 2014/30/EU.

All VCCM600 series power supplies must be installed correctly in a controlled environment which restricts access to any un-authorised personnel. Equipment and

system manufacturers must protect service personnel against unintentional contact with the output terminals.

HAZZARDS

Dangerous voltages are present within the power supply. It should only be handled by qualified personnel when the power supply has been disconnected from

the mains supply voltage for more than 3 minutes.

External surfaces of the power supply may become extremely hot during and after operation. Appropriate care should be taken.

If series and/or parallel combinations of outputs exceed safe voltage and/or energy levels, the final equipment manufacturer must provide the appropriate

protection for both users and service personnel.

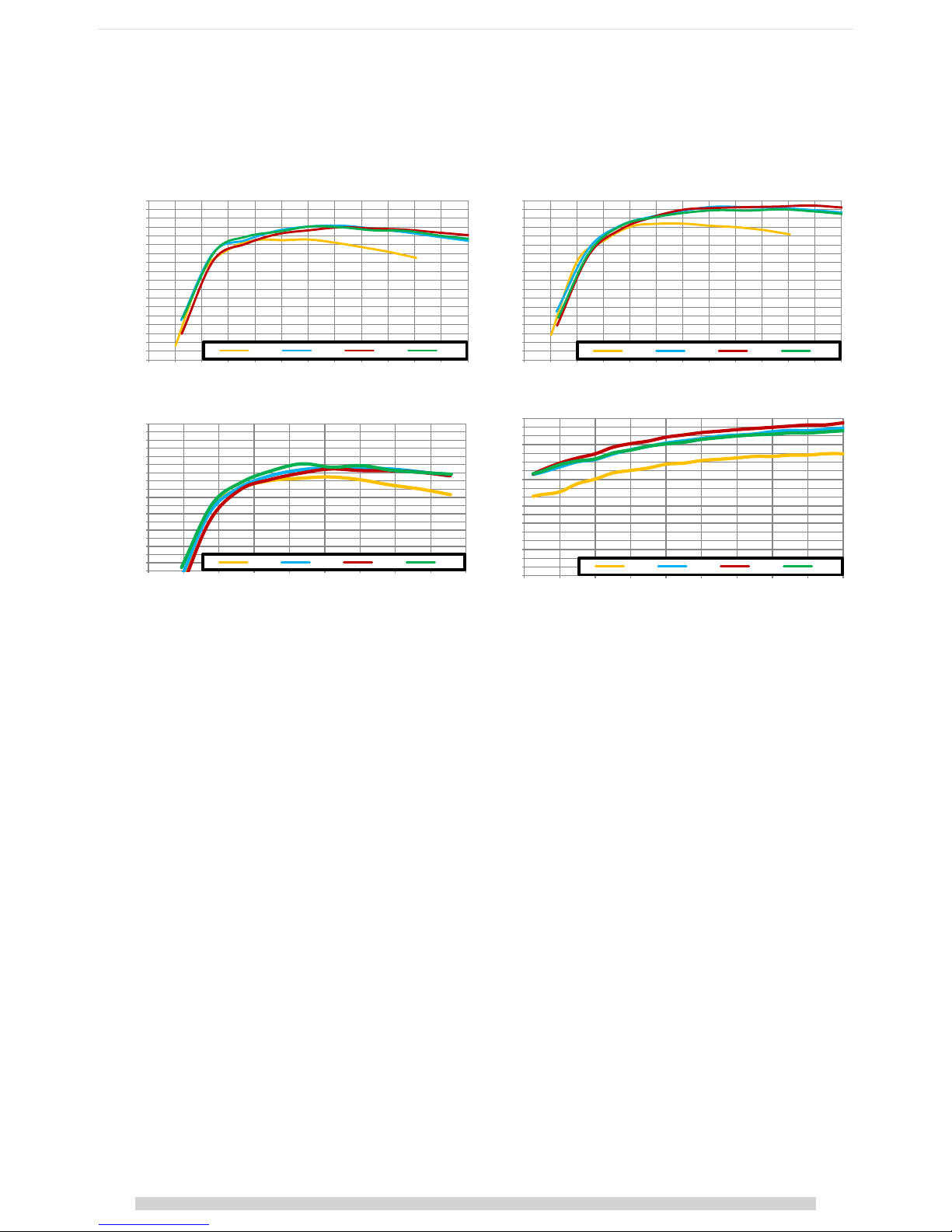

DE-RATINGS

Remember to take the appropriate de-rating into consideration before specifying any VCCM600 power supply for an application. If in any doubt, please contact

Vox Power directly or your local Vox Power representative.

HEALTH AND SAFETY

To comply with section 6 of the health and safety at work act, a label that is clearly visible to service personnel must be placed on the final equipment. These

labels warn that surfaces of the power supply may be hot and should not be touched when the product is operating.

FUSING

The power supply has internal dual pole fusing. One fuse in each line.

Fuses should only be replaced by authorised personnel and to ensure continued protection against risk of fire, fuses must be replaced with the same type and

rating of fuse.

For DC operation, an appropriately rated DC fuse must be included in the end application.

SERVICING

The power supply contains no user serviceable parts. Repairs must be carried out by authorised personnel only. Contact Vox Power for further information.

APPROVAL LIMITATIONS – NORTH AMERICA

When this product is used with 180VAC–253VAC mains where no neutral is present, connect the two live wires to L (Live) and N (Neutral) on the input connector.

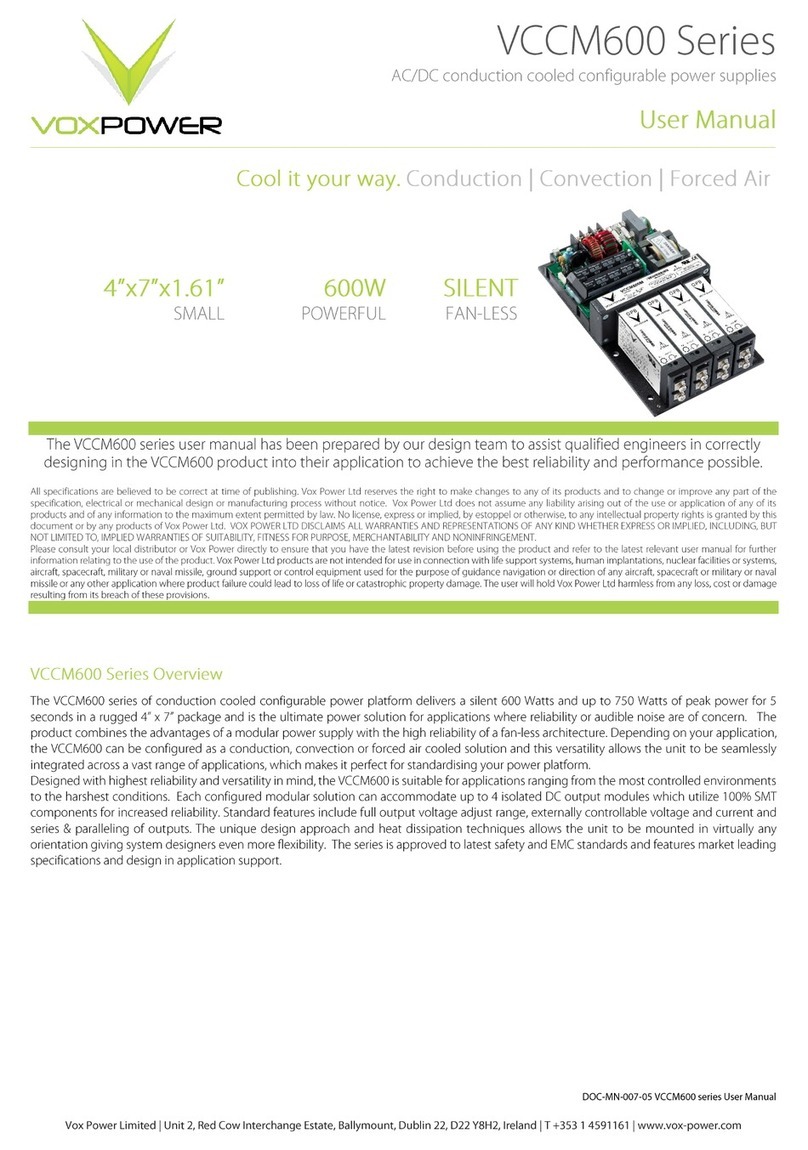

COOLING

For proper operation of the power supply, the user must ensure sufficient cooling to maintain all component temperatures within specifications. A thorough

review of the user manual should be carried out for details of thermal performance.

EARTH TERMINAL MARKING

To comply with the requirements of UL60950-1, IEC/EN60950-1, CSA22.2 no. 60950-1, UL60601-1, IEC/EN60601-1, CSA22.2 no 601-1 where the incoming wiring

earth is intended for connection as the main protective earth conductor and where the terminals for such a connection is not supplied on a component or

subassembly, the user shall add an appropriate label displaying a protective earth symbol in accordance with 60417-2-IEC-5019 directly adjacent to the terminal.

The label should be durable and legible and should withstand the 15 second rub test as per UL60950-1 section 1.7.15.

WARRANTY

Contact your sales agent or Vox Power for product repairs. See Vox Power standard terms and conditions for warranty conditions.

PRODUCT LABELS

The external product label contains information relevant to the power system. The label contains input voltage, maximum input current, input frequency,

maximum output power, fuse rating and type, serial number, approvals and product part number in form VCCM600x-yyyy-zzz.

VCCM OUTPUT MODULES

Each output module label contains information relevant to that output. The label contains voltage adjustment range, maximum output current, serial number,

approvals and the part number in format OPx.

OTHER

•A label warning that external surfaces are hot during operation and that the unit should be allowed to cool down properly should be placed on the

unit where such a label is clearly visible.

•The VCCM600 series is designed to comply with EMC standards but it does not imply that the end system will comply.

•To prolong the life of the unit, use in dust free environment.

•Units can sometimes be damaged during transit. In the event of transit damage, DO NOT connect power to the unit. Contact your sales agent or Vox

Power.

•Always use adequately sized cables and ensure good crimp connections. Use cable supports to minimise stress on connectors.

•Avoid excessive shock or vibration.