Table of contents

2 / 33 B-H86.0.11.DB201-1.0

Table of contents

1 Legal address of the manufacturer................................................................................................... 4

2 About this documentation ................................................................................................................. 5

2.1 Foreword............................................................................................................................................... 5

2.2 Purpose of the document...................................................................................................................... 5

2.3 Warranty ............................................................................................................................................... 5

2.4 Compliance with local laws and other legal regulations ....................................................................... 5

2.5 Correctness of content.......................................................................................................................... 6

2.6 Layout of this document........................................................................................................................ 6

2.7 Further information ............................................................................................................................... 6

3 Safety ................................................................................................................................................... 8

3.1 Explanation of safety symbols .............................................................................................................. 8

3.2 Foreseeable misuse ............................................................................................................................. 8

3.3 Safety instructions ................................................................................................................................ 9

3.4 Intended use ....................................................................................................................................... 10

3.5 Qualified personnel............................................................................................................................. 10

4 Description ........................................................................................................................................ 11

4.1 Scope of delivery ................................................................................................................................ 11

4.2 Job description.................................................................................................................................... 11

5 The product at a glance ................................................................................................................... 12

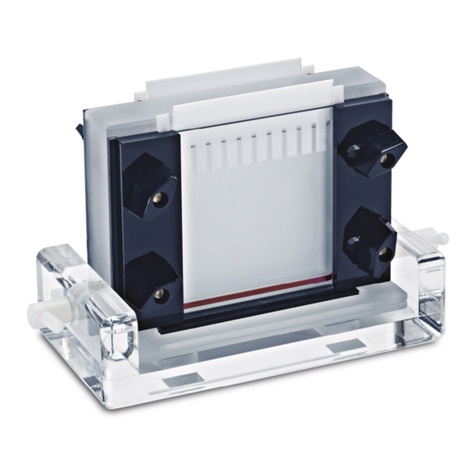

5.1 The PH20............................................................................................................................................ 12

5.2 Display elements ................................................................................................................................ 12

5.3 Operating elements ............................................................................................................................ 12

5.4 Connections........................................................................................................................................ 13

6 Bases for measurement ................................................................................................................... 14

6.1 pH measurement ................................................................................................................................ 14

6.1.1 Explanation ......................................................................................................................................... 14

6.1.2 pH electrode ....................................................................................................................................... 14

6.1.3 Design................................................................................................................................................. 14

6.1.4 Further information ............................................................................................................................. 15

6.1.5 Choosing a pH electrode .................................................................................................................... 15

6.1.6 Care and maintenance ....................................................................................................................... 15

7 Maintenance ...................................................................................................................................... 17

7.1 Operating and maintenance notices ................................................................................................... 17

7.2 Battery ................................................................................................................................................ 17

7.2.1 Battery indicator.................................................................................................................................. 17

7.2.2 Changing battery ................................................................................................................................ 18

7.3 Calibration and adjustment ................................................................................................................. 19

7.3.1 pH calibration...................................................................................................................................... 19

8 Operation........................................................................................................................................... 23

8.1 Commissioning ................................................................................................................................... 23

8.1.1 Explanation ......................................................................................................................................... 23

8.2 Configuration ...................................................................................................................................... 23

8.2.1 Explanation ......................................................................................................................................... 23

8.2.2 Opening the configuration menu......................................................................................................... 23