H76.0.24.6C-01_VWR Operating Manual TD142 page 3 of 16

_____________________________________________________ _____________________________________________________________________________

Index

1GENERAL NOTE............................................................................................................... 3

2SAFETY ............................................................................................................................... 4

2.1 INTENDED USE.................................................................................................................. 4

2.2 SAFETY SIGNS AND SYMBOLS............................................................................................ 4

2.3 SAFETY GUIDELINES ......................................................................................................... 5

3PRODUCT SPECIFICATION .......................................................................................... 6

3.1 SCOPE OF DELIVERY.......................................................................................................... 6

3.2 OPERATION AND MAINTENANCE ADVICE........................................................................... 6

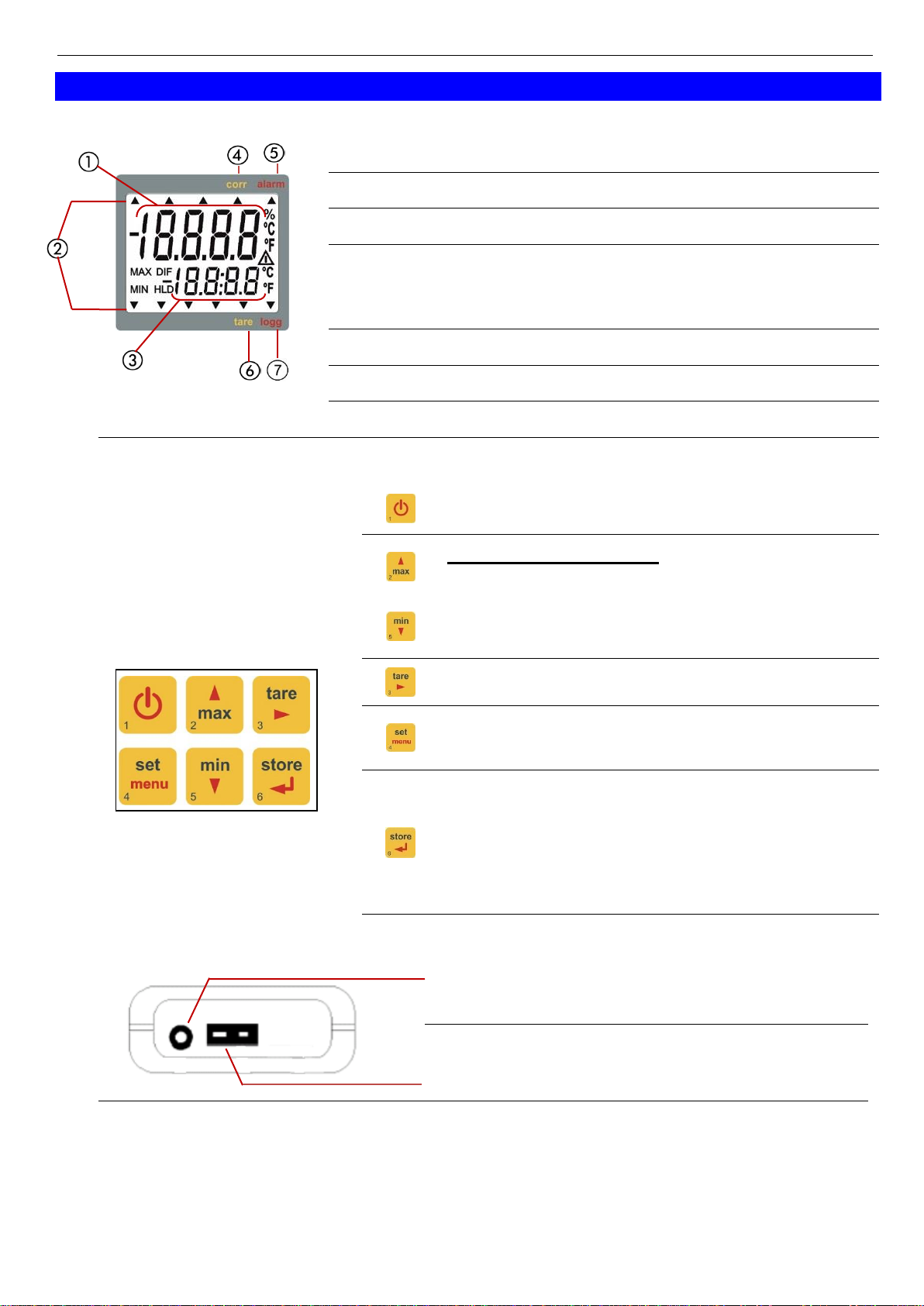

4HANDLING......................................................................................................................... 7

4.1 DISPLAY ........................................................................................................................... 7

4.2 BASIC OPERATION ............................................................................................................ 7

4.3 CONNECTIONS................................................................................................................... 7

4.4 POP-UP CLIP ...................................................................................................................... 8

5START OPERATION ........................................................................................................ 8

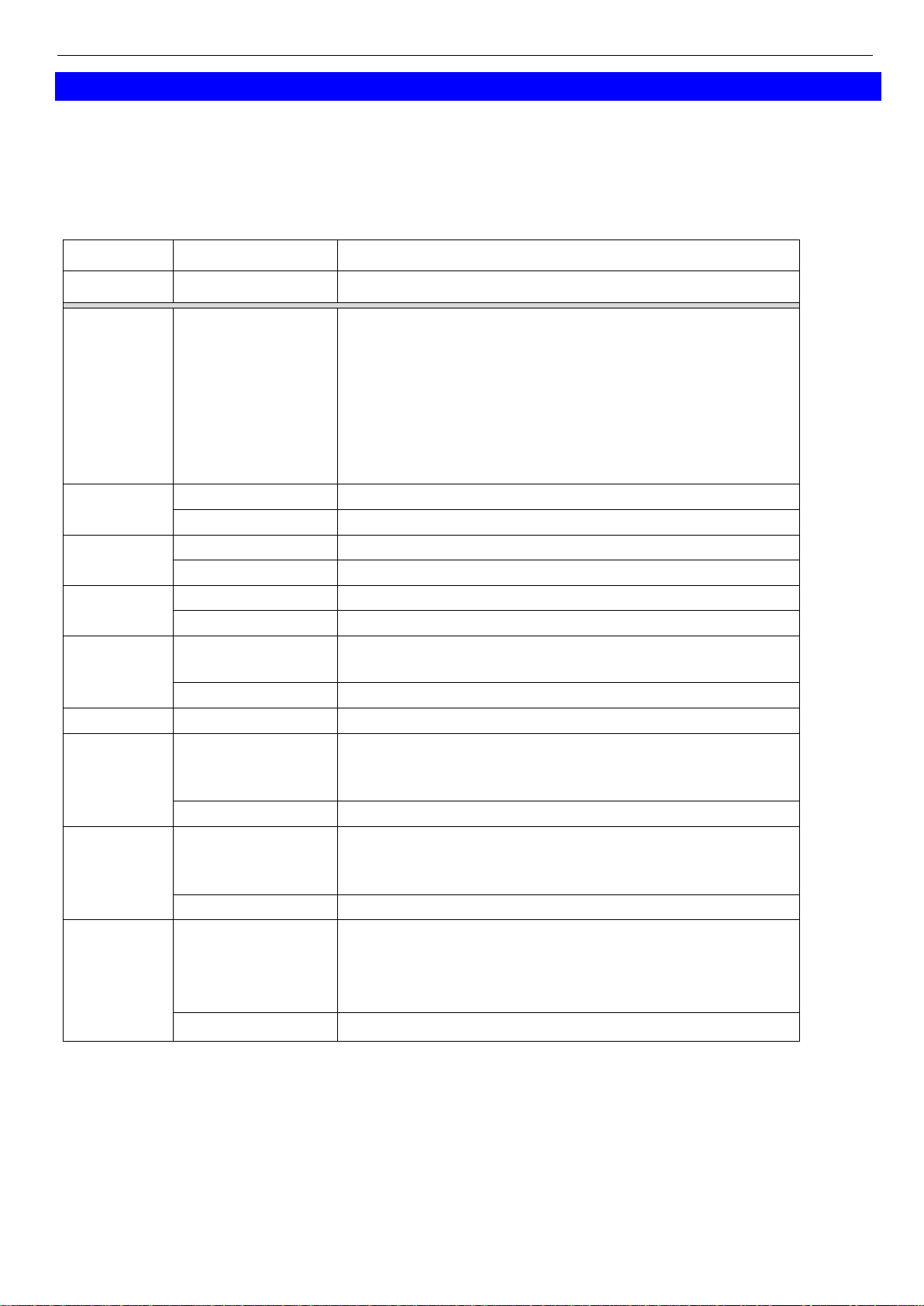

6DEVICE CONFIGURATION ........................................................................................... 9

7REMARKS TO SPECIAL FEATURES.........................................................................10

7.1 BASE ADDRESS (’ADR.’)................................................................................................. 10

7.2 POWER OFF TIME ............................................................................................................ 10

8OUTPUT ............................................................................................................................11

8.1 SERIAL INTERFACE ......................................................................................................... 11

9ADJUSTMENT ................................................................................................................. 12

9.1 ZERO DISPLACEMENT ..................................................................................................... 12

9.2 SCALE CORRECTION ....................................................................................................... 12

9.3 CORRECTION FOR SURFACE MEASURING ......................................................................... 12

10 FAULT AND SYSTEM MESSAGES ..........................................................................13

11 SPECIFICATION ..........................................................................................................13

12 TECHNICAL SERVICE...............................................................................................15

13 WARRANTY..................................................................................................................15

14 EQUIPMENT DISPOSAL ............................................................................................ 15

1 General Note

Read this document carefully and get used to the operation of the device before you

use it. Keep this document within easy reach near the device for consulting in case

of doubt.