2789-9080 Table of Contents

Product manual | Version: 1.0.0 iii

IO-Link Communication Module

Table of Contents

1Provisions ........................................................................................................................5

1.1 Intended Use ...........................................................................................................5

1.2 Typographical Conventions .....................................................................................6

1.3 Legal Information.....................................................................................................8

2Safety ................................................................................................................................9

2.1 General Safety Rules ..............................................................................................9

2.2 Electrical Safety.......................................................................................................9

2.3 Mechanical Safety ...................................................................................................9

2.4 Thermal Safety ......................................................................................................10

2.5 Indirect Safety........................................................................................................10

3Properties .......................................................................................................................11

3.1 Overview................................................................................................................11

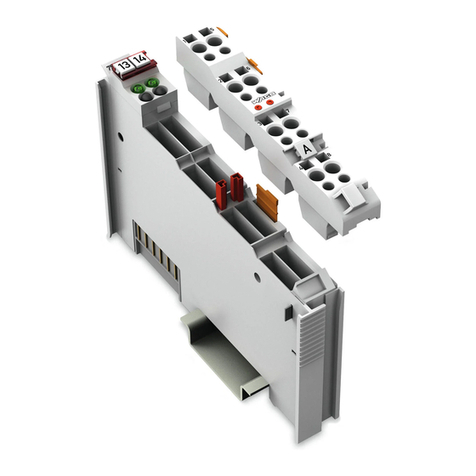

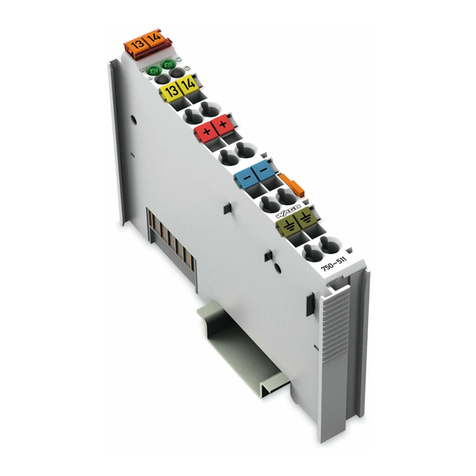

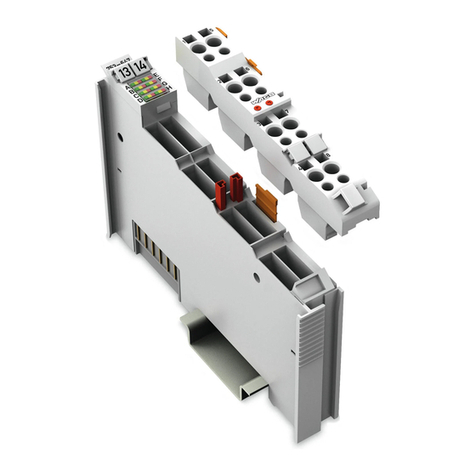

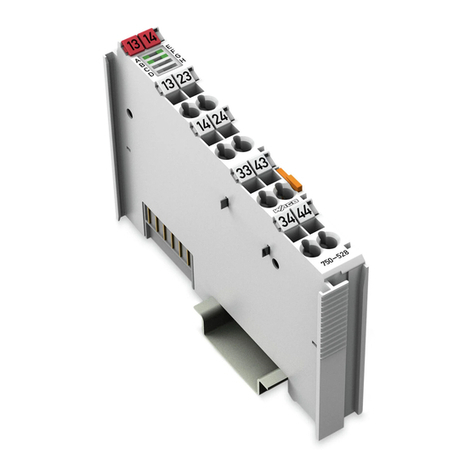

3.2 View.......................................................................................................................11

3.3 Type label ..............................................................................................................12

3.4 Product-Specific Information .................................................................................13

3.5 Connections...........................................................................................................13

3.5.1 IO-Link..........................................................................................................13

3.6 Indicators ...............................................................................................................14

3.7 Technical data .......................................................................................................14

3.7.1 Product .........................................................................................................14

3.7.2 Input..............................................................................................................14

3.7.3 Power Loss...................................................................................................15

3.7.4 Communication.............................................................................................15

3.7.5 Environmental Requirements .......................................................................15

3.8 Guidelines, approvals and standards ....................................................................15

3.8.1 Guidelines ....................................................................................................15

3.8.2 Approvals......................................................................................................16

3.8.3 Standards .....................................................................................................16

4Fieldbus Description .....................................................................................................17

4.1 Technology ............................................................................................................17

4.1.1 IO-Link Technology ......................................................................................17

4.1.2 IO-Link – Functions ......................................................................................17

4.2 Parameters ............................................................................................................18

4.2.1 General Module Parameters ........................................................................18

4.2.2 Specific Module Parameters of the WAGO Power Supply Pro 2 ................. 19

4.2.3 Data Structure for WAGO Power Supplies Pro 2 ......................................... 19

4.2.4 Parameter Addresses for WAGO Power Supplies Pro 2 .............................20

4.2.4.1 Password Handling ............................................................................. 21

4.2.4.2 Baud Rate (Index 380) ........................................................................ 22

4.2.4.3 Data bits (Index 382)........................................................................... 22