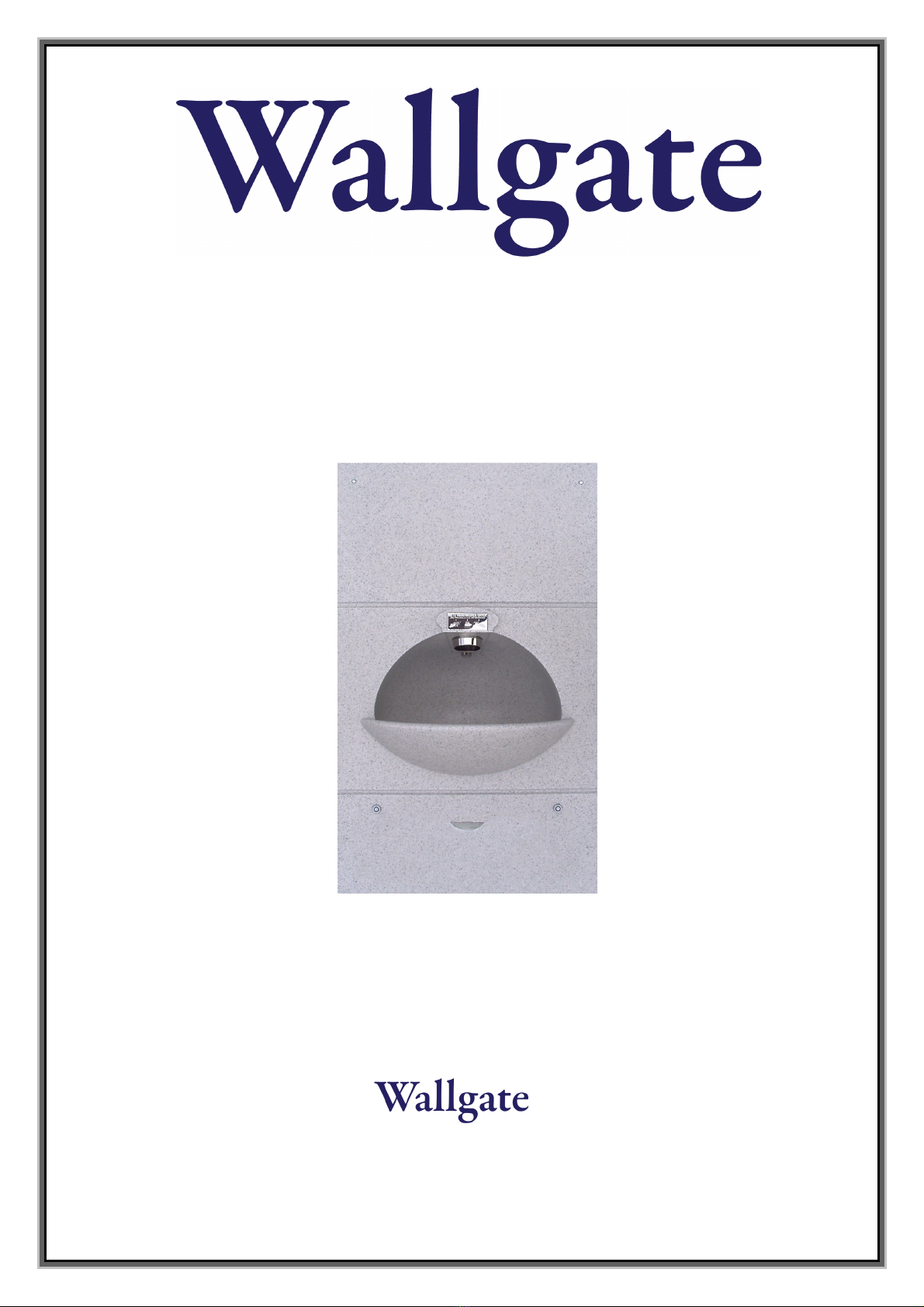

safe place. Cut away the plastic film around the unit and remove the four polystyrene

support corners. Do not pick up the unit by the fascia panel edges but support it below the

white cabinet.

(d) Using a RESIST-TORX T30 security key undo the two screws on the unit top fascia panel

and lift the panel off. Place it in a safe place resting on its rear face.

(e) Release the three screws securing the inner top panel metal cover & remove panel. If

more than one unit is being installed, ensure the panels are kept with each unit.

(f) Using the other key type provided, unlock the lower drawer locks (2). Pull open the drawer

& remove the plastic soap container & hook over the soap tube and priming switch into

the wash basin on the unit.

(g) Remove the drawer from the unit by pressing the black plastic levers that are located on

each slide. Note that the left lever should be pressed down while the right lever is lifted

up. Pull the drawer out from the unit until it is released from the slides. This operation may

require two people or alternately stand the unit up on its base with a pad below it to raise

the drawer off floor level.

(h) Move the unit to the aperture and pass the electrical supply cable through the entry hole

on the back of the cabinet (located towards left-hand side).

(i) Lift the unit up into the aperture and secure to the mounting plates with the bolts &

washers provided. Tighten (hand tight only) the bolts half way into the bushes only at this

stage.

(j) Adjust the brass nuts on the bushes by unscrewing them so that they meet the sides of

the cabinet. The nuts must be adjusted evenly each side so that the cabinet is positioned

centrally in the aperture. Extra care must be taken with the two lower points to avoid

distorting the cabinet sides in too far which will then prevent the satisfactory operation of

the drawer in its slides. The cabinet sides should be set apart a distance of 541mm (21

5/16”) to their outer edges. Once all four points are set, press the unit fully into the

aperture and tighten the four bolts.

4. ELECTRICAL CONNECTION.

WARNING: This appliance must be earthed.

(a) The CME is designed for a fixed wire type installation.

(b) The unit should be installed by a qualified electrician in accordance with the current

Nationally Approved Regulations (IEE).

(c) Terminate the supply cable into the terminal block positions “L E N” located on the left

side within the cabinet and secure it within the cable clamp. The supply cable must not

come into contact with any other components or wiring within the unit.

(d) Earth bonding should be carried out to comply with the Nationally Approved Regulations

(IEE). Connections must be made to the following points: Water supply pipe, Sink waste

outlet & Equipotential earth connection for bonding together multiple units installed,

(connection positioned on back of cabinet behind drawer).

5. WATER SUPPLY & WASTE CONNECTION.

IMPORTANT! For installations liable to freezing conditions, frost protection & pipe insulation

must be fitted.

(a) Prior to final connection of the water supply to the unit, the pipes must be flushed through

so as to remove any debris & air locks.

Warning: Failure to carry this out may result in damage and failure of the unit.

(b) Complete the water connection to the plastic tap/flow regulator on the unit, taking care

that any sealing compounds used are not excessively applied, which may cause a

blockage.

(c) For the waste connection an appropriate trap (not supplied, recommend McAlpine type

SB10 or SP10) should be fitted to the units sink waste (1 ¼” BSP). Ensure the trap is

positioned only on the centre line of the unit so that it does not interfere with the drawer

unit. Final connection can then be made to the main waste pipe.