2| P a g e

Wallgate Thrii®

PRODUCT MANUAL Issue 5_3

ORIGINAL INSTRUCTIONS

© 2013 Wallgate Ltd.

Contents

1. Disclaimer& Copyright notice .....................................................................................................3

2. Conventions ................................................................................................................................4

2.1 Warning...............................................................................................................................4

2.2 Caution................................................................................................................................4

2.3 Important ............................................................................................................................4

2.4 Numbered procedures........................................................................................................4

2.5 Bullet lists............................................................................................................................4

2.6 Menu items .........................................................................................................................4

3. Glossary.......................................................................................................................................5

4. Technical Specification................................................................................................................6

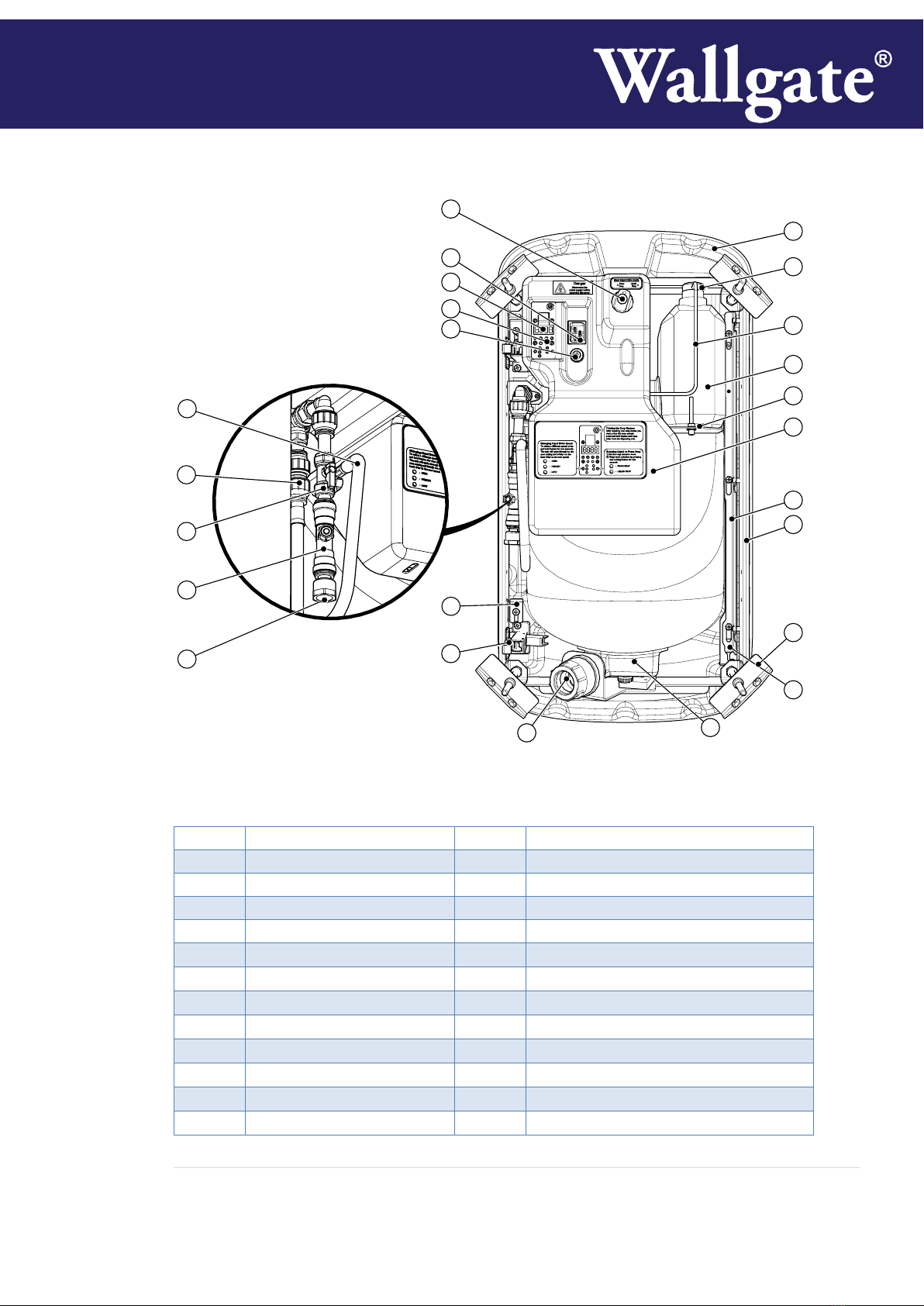

5. Overview .....................................................................................................................................7

6. Installation and Commissioning................................................................................................10

6.1 Package Contents..............................................................................................................10

6.2 Site Preparation ................................................................................................................10

6.3 Installing the support frame, water and waste connections and electric ........................11

6.4 Mounting the fascia ..........................................................................................................16

6.5 Engine installation.............................................................................................................18

6.6 Electrical and Water Connections.....................................................................................20

6.7 Commissioning for use......................................................................................................21

7. Programme settings..................................................................................................................23

7.1 Operation ..........................................................................................................................24

7.2 Advanced adjustment .......................................................................................................25

8. Care, Routine maintenance, Service & Repair..........................................................................26

8.1 Care /Cleaning...................................................................................................................26

8.2 Routine maintenance........................................................................................................26

8.3 Service and Repair.............................................................................................................26

8.4 Spare parts ........................................................................................................................27