INSTALLATION & COMMISSIONING INSTRUCTIONS.

HAND WASH DRIER MODELs FMX-20 & 25.

CONTENTS

Ensure the following items are in the box on unpacking:

1 x FMX

Hand wash drier unit - 2 x Installation plates

4 x Door keys - 1 x 2.5ltr Soap container

1 x Installation & operating manual.

1. SITE PREPARATION

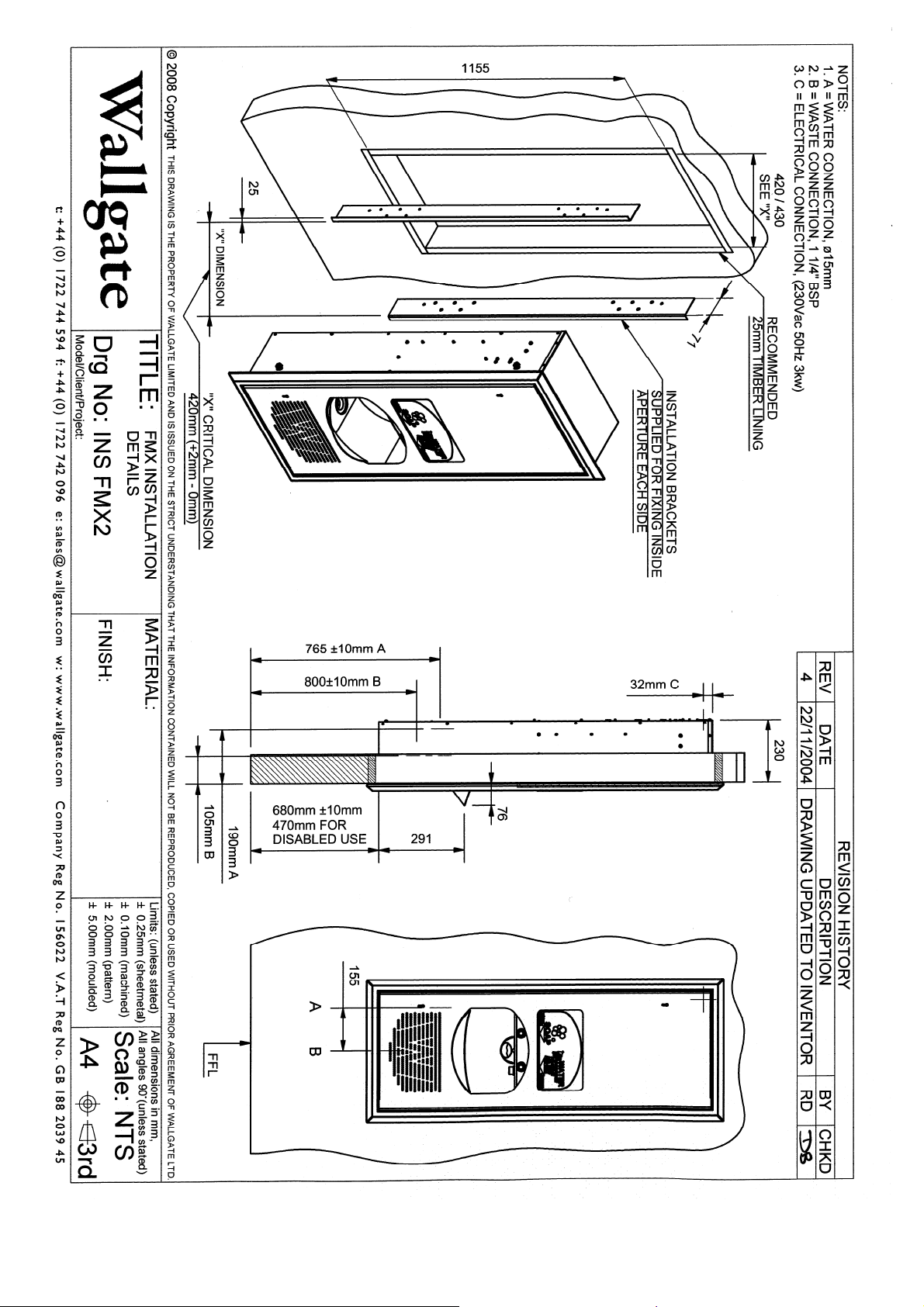

a) Prepare an opening in the wall surface, accurate to the dimensions shown on the installation

drawing “INSFMX2”. It may be preferable to build a stud wall to house the unit as an

alternative to preparing an aperture in an existing wall.

b) To achieve greater accuracy, it is recommended that a timber lining is fitted to the aperture.

The material thickness should be allowed for in the aperture dimensions.

c) The unit is not designed to provide support above the opening. If this is required, a suitable

lintel should be provided.

d) An electrical supply should be provided with a switched fused spur - 13amp, double pole

connection point that is local to the unit (the contact separation of the fused spur switch

should be at least 3mm).

e) A suitable cable with a minimum conductor size of 1.5mm sq should be connected to the

fused spur switch ready for connection to the unit.

f) A mains cold water supply with a min pressure of 1.75bar should be provided within the wall

cavity below the aperture and terminated with a suitable isolating tap. Final connection to

the hand wash unit water inlet (15mm compression) may be made with a flexible mains

rated hose.

g) A waste outlet connection of 32mm (1¼") should be provided within the wall cavity below the

aperture.

IMPORTANT: The installer should seek further advice from the manufacturer when

considering connection to gravity fed water system.

2. APPLIANCE PREPARATION & FITTING

a) Fit the installation plates to the sides of the aperture ensuring that they are level with each

other in all planes using 8 suitable fasteners. Remove the M8 bolts & washers from the

plates (4 off).

b) Move the unit from its packaging to the aperture and then pass the mains cable into the

electrical entry point on the rear of the cabinet.

c)

Carefully insert the unit fully into the wall aperture ensuring that the supply cable does not

become trapped. Using the keys provided, open the door panel and remove the plastic

installation cover by releasing the four screw fasteners. Ease the cover out of the unit on the

left side first, and pass the soap tube back into the cabinet.

3. ELECTRICAL CONNECTION

WARNING: This Appliance must be Earthed

a) The

UNI-WASH

unit is designed for a fixed wire type installation.

b) The unit should be installed by a qualified electrician in accordance with the current

Nationally Approved Regulations (IEE).