©2019 Warn Industries, Inc.WARN® and the WARN logo are trademarks of Warn Industries Inc. 1 105916A0

WARN INDUSTRIES, INC. 12900 S.E. Capps Road,

Clackamas, OR USA 97015-8903, 1-503-722-1200, FAX: 1-503-722-3000

Customer Service: 1-800-543-9276

Dealer Locator Service: 1-800-910-1122

International Sales/Customer Service: 1-503-722-3008

International Fax: 1-503-722-3005

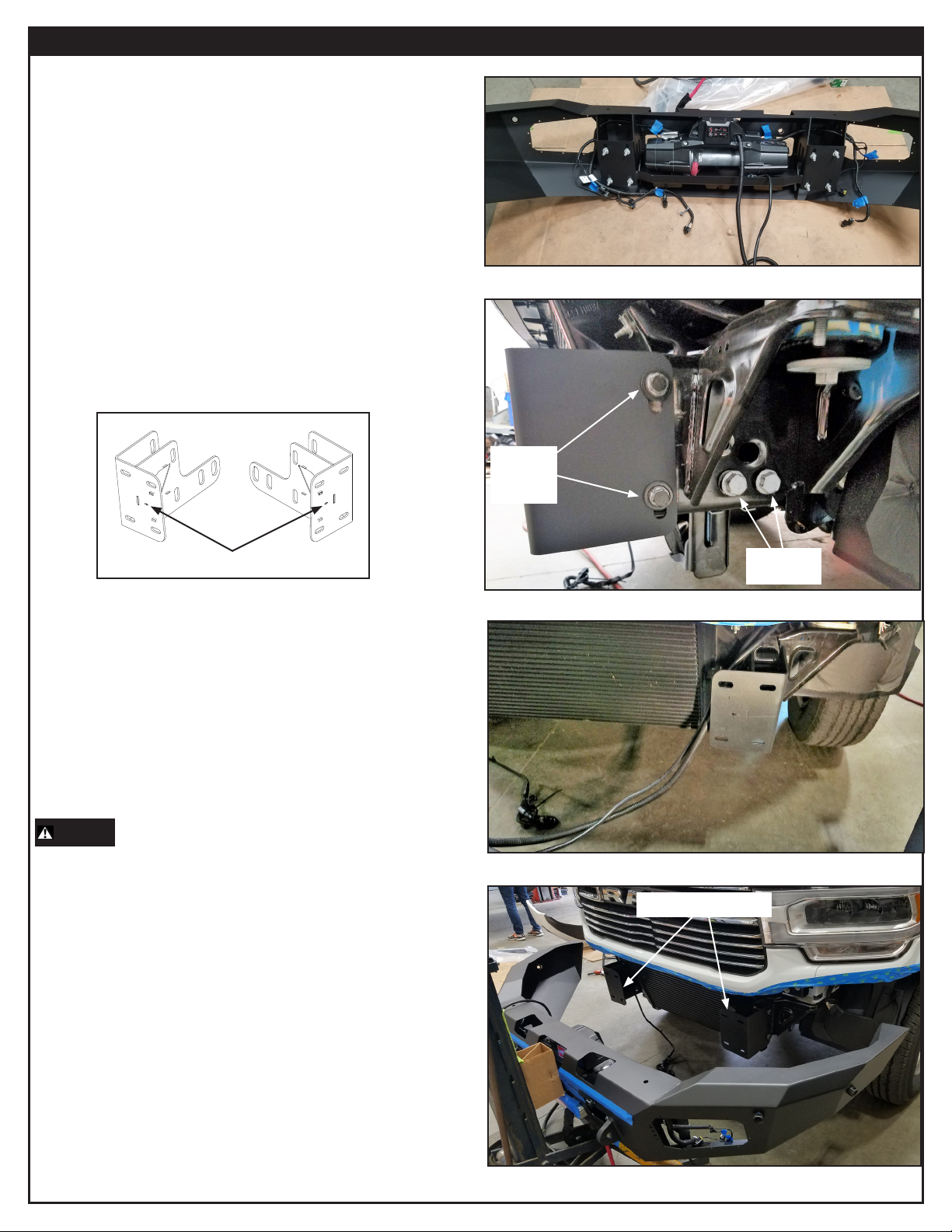

INSTALLATION INSTRUCTIONS

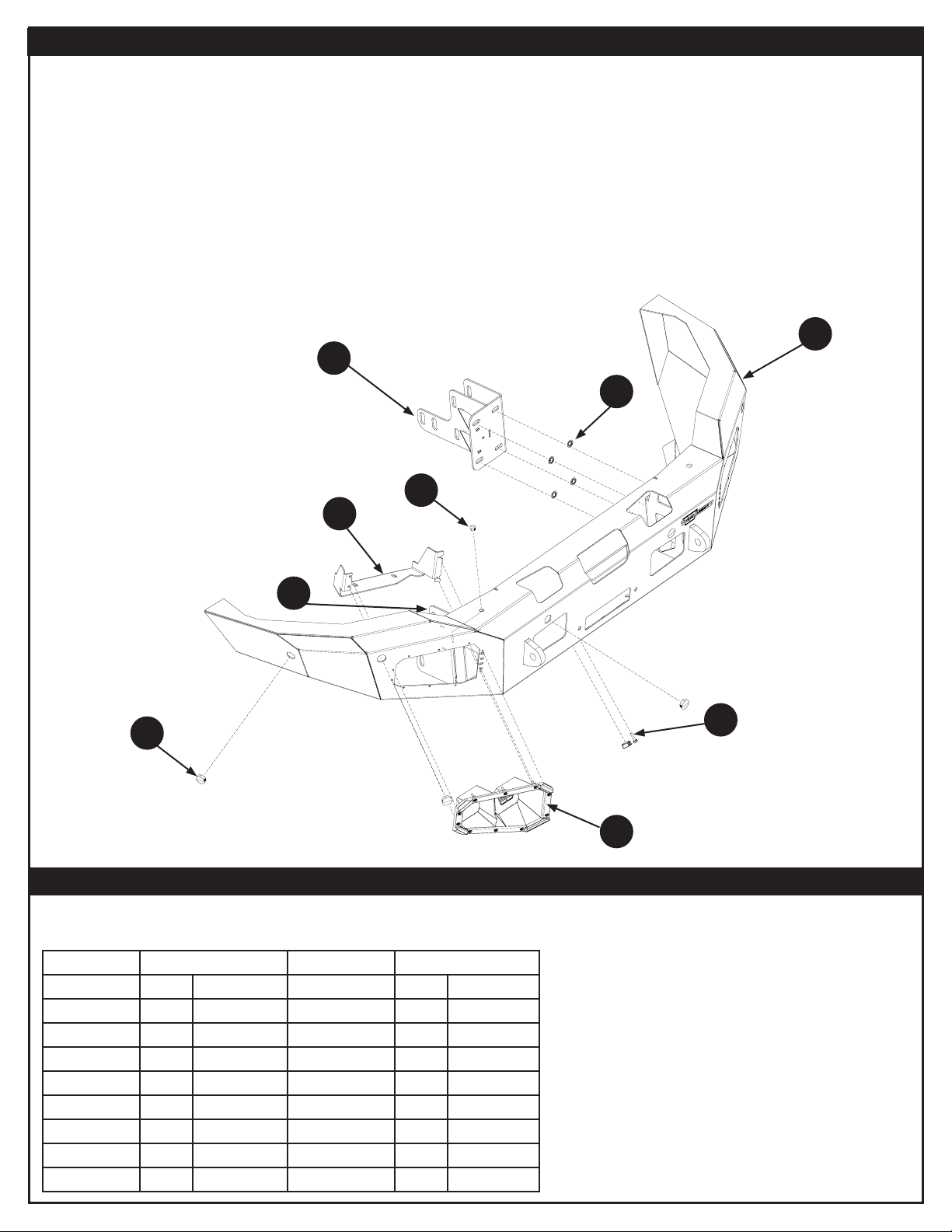

ASCENT FRONT BUMPER KIT

Part Number: 104256

Application: 2019 Dodge Ram 2500/3500

Your safety, and the safety of others, is very important. To help you make informed decisions about safety, we have provided installation

and operating instructions and other information on labels and in this guide. This information alerts you to potential hazards that could

hurt you or others. It is not possible to warn you about all potential hazards associated with this product, you must use your own good

judgment.

CARELESS INSTALLATION AND OPERATION CAN RESULT IN SERIOUS INJURY OR EQUIPMENT DAMAGE. READ AND UNDERSTAND

ALL SAFETY PRECAUTIONS AND OPERATING INSTRUCTIONS BEFORE INSTALLING AND OPERATING THIS PRODUCT.

This guide identies potential hazards and has important safety messages that help you and others avoid personal injury or death.

WARNING and CAUTION are signal words that identify the level of hazard. These signal words mean:

WARNING signals a hazard that could cause serious injury or death, if you do not follow recommendations. CAUTION signals a

hazard that may cause minor to moderate injury, if you do not follow recommendations.

This guide uses NOTICE to call attention to important mechanical information, and Note: to emphasize general information worthy of

special attention.

WARNING

IMPACT AND MOVING PARTS ENTANGLEMENT HAZARD

Failure to observe these instructions could lead to severe injury or death

• Always Know Your Winch. Take time to fully read the Instructions and/or Operations Guide, and/or Basic Guide to Winching Techniques, in order to understand

your winch and its operations.

• Never work under vehicle before properly securing vehicle.

• Always use appropriate and adequate care in lifting components into place.

• Never work under vehicle before properly securing vehicle.

• Always use appropriate and adequate care in lifting components into place.

• Never use a jack to support the vehicle.

• Always use jack stands in pairs to support the vehicle.

• Always use jacks or jack stands only on a hard, stable, and level surface.

• Never exceed the rated capacity of a jack or jack stands.

• Always verify that the parking brake is set, the transmission is in park (automatic) or reverse (manual) and the rear wheels are blocked before working on vehicle.

• Never work under vehicle before properly securing vehicle.

• Always use appropriate and adequate care in lifting components into place.

• Always insure components will remain secure during installation and operation.

• Always tighten all nuts and bolts securely, per the installation and operation.

• Always perform regular inspections and maintenance on the winch, winch mount and related hardware.

• Always replace all worn or damaged parts before operating.

• Never operate this WARN product with damaged or missing parts.

• Always use extreme caution when drilling on any vehicle. Make sure that all fuel lines, brake lines, electrical wires, and other objects are not punctured or

damaged when / if drilling on the vehicle. Thoroughly inspect the area to be drilled (on both sides of material) prior to drilling, and relocate any objects that may

be damaged. Failure to inspect the area to be drilled may result in vehicle damage, electrical shock, re or personal injury.

• Always use extreme caution when cutting and trimming during tting.

• Always wear safety glasses when installing this kit. A drilling operation will cause ying metal chips. Flying chips can cause eye injury.

• Always remove jewelry and wear eye protection.

• Never lean over battery while making connections.

• Never route electrical cables across any sharp edge, through or near moving parts, near parts that become hot.

Read installation and operating instructions thoroughly.

GENERAL SAFETY PRECAUTIONS