WaterLogic WL100 Operating instructions

Other WaterLogic Water Filtration System manuals

WaterLogic

WaterLogic WL500 - Sparkling User manual

WaterLogic

WaterLogic escowa Purus iQ3 User manual

WaterLogic

WaterLogic WL270 Manual

WaterLogic

WaterLogic WL100 Reference guide

WaterLogic

WaterLogic WL7 User manual

WaterLogic

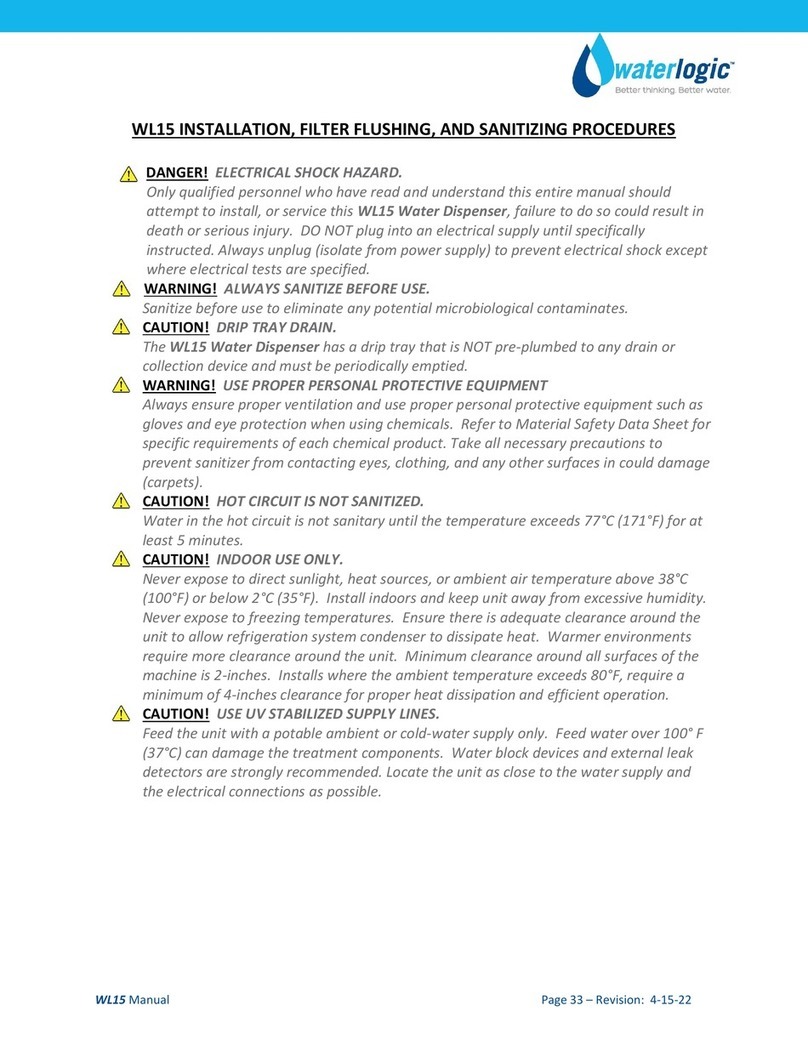

WaterLogic WL15 User manual

WaterLogic

WaterLogic F-FWEG1-M-A-NT Series User manual

WaterLogic

WaterLogic F-FWEG1-M-A-NT Series User manual

WaterLogic

WaterLogic Countertop Pure K-FU-00S20-00C1L-13-0-XXX User manual

WaterLogic

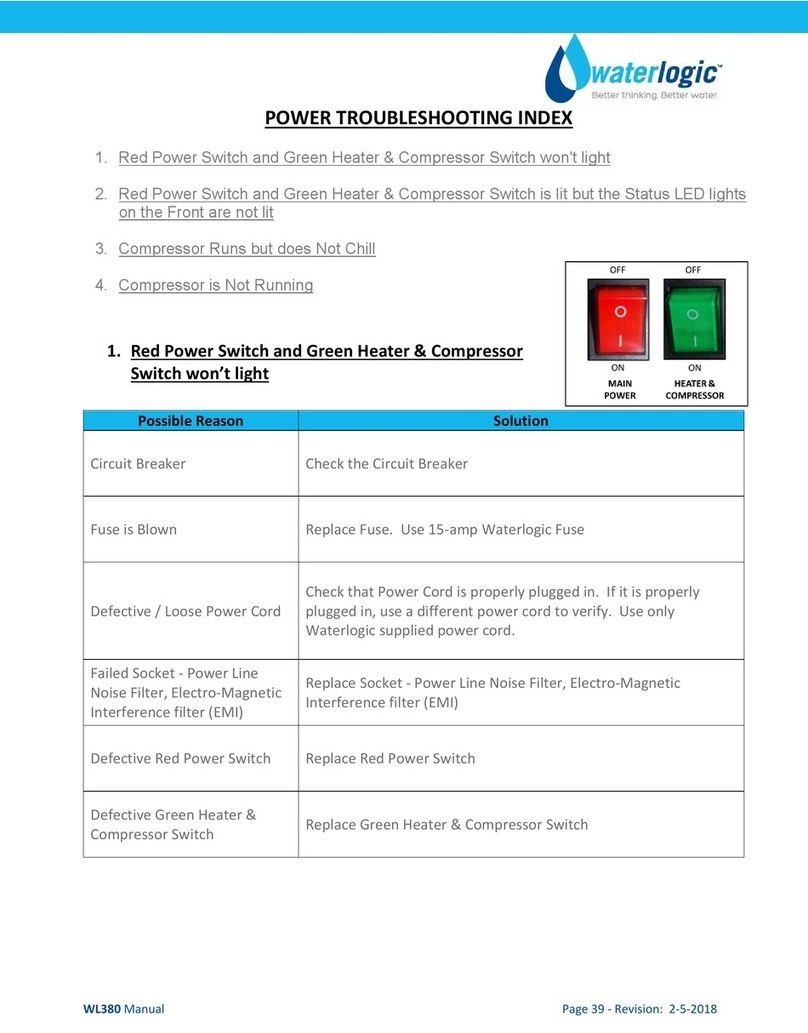

WaterLogic WL380 Operating instructions

WaterLogic

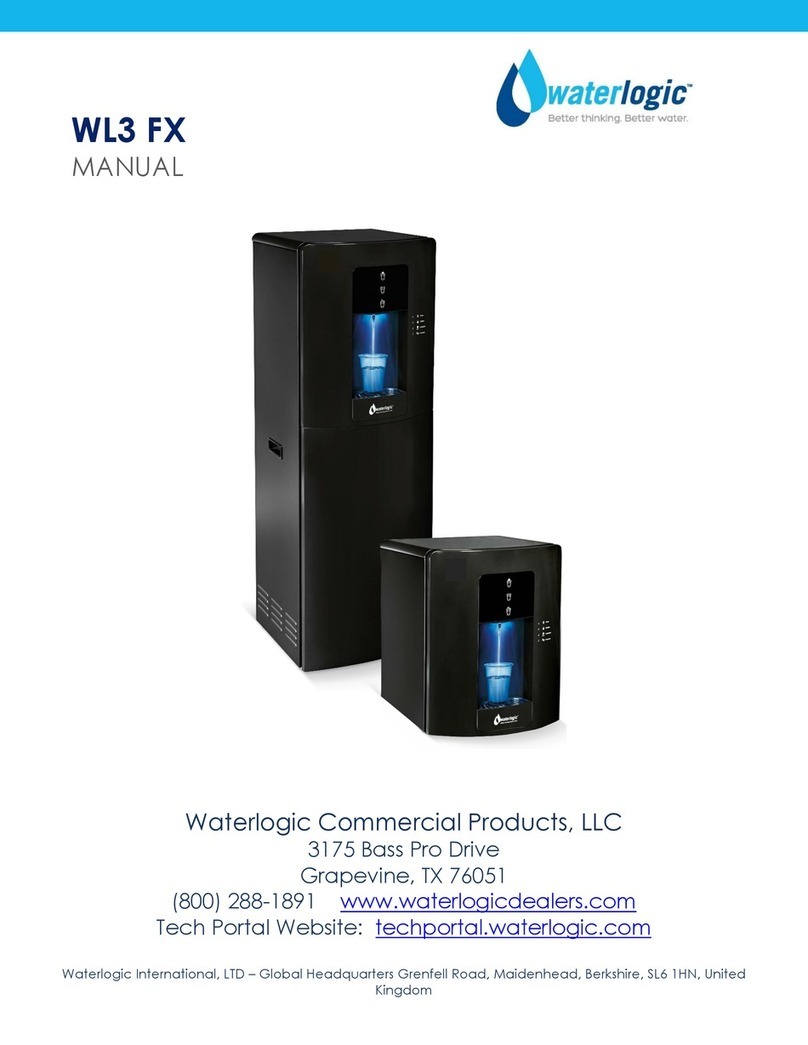

WaterLogic WL3 FX User manual

WaterLogic

WaterLogic Water Filtration Systems User manual

WaterLogic

WaterLogic WL100 Operating instructions

WaterLogic

WaterLogic WL270 User manual

WaterLogic

WaterLogic WLH2 Classe Operating and maintenance manual

WaterLogic

WaterLogic WL100 Operating instructions

WaterLogic

WaterLogic WL3 IT User manual

WaterLogic

WaterLogic WL15-HCS User manual

WaterLogic

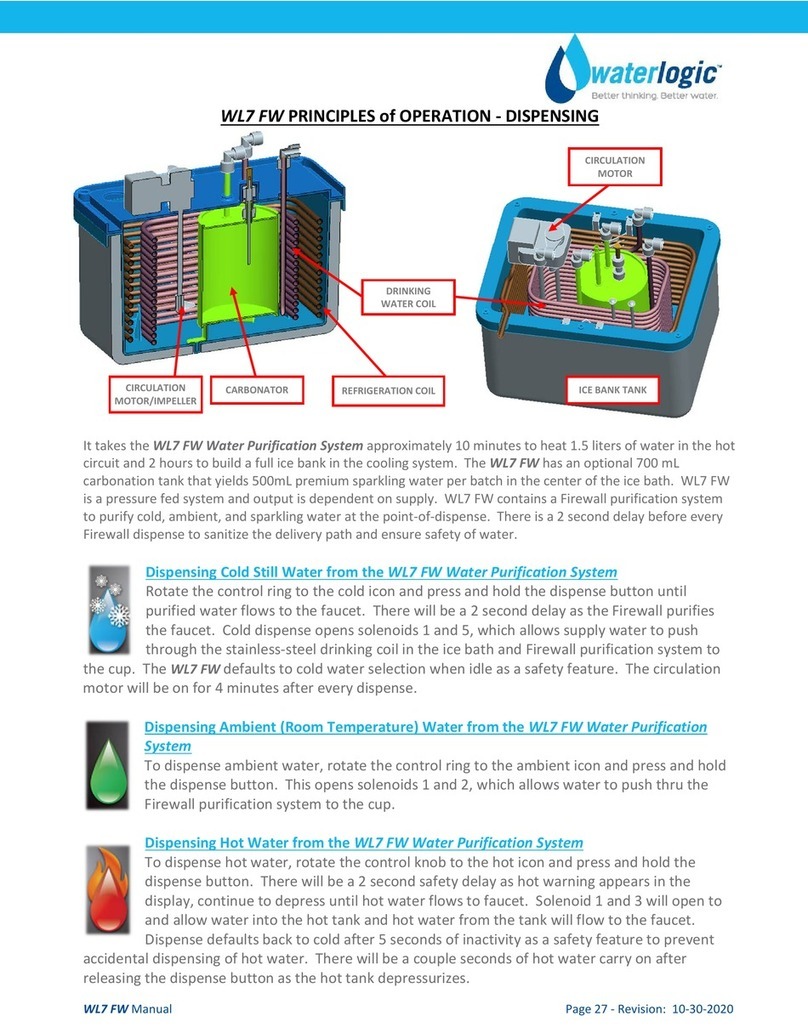

WaterLogic WL7 FW Reference guide

WaterLogic

WaterLogic WL7 User manual

Popular Water Filtration System manuals by other brands

Prio

Prio Expert M400 user guide

Braun

Braun Aquaboss (Eco) RO Dia II HT operating instructions

XPOtool

XPOtool 63342 user manual

Emerson

Emerson ALCO ADKS Series operating instructions

PUR

PUR BOOSTER QUICK 7 Steps -400 GPD Installation and maintenance manual

HYDAC FILTER SYSTEMS

HYDAC FILTER SYSTEMS OF5 S Series Installation and maintenance instructions