WaterLogic WL100 Operating instructions

Other manuals for WL100

7

Other WaterLogic Water Filtration System manuals

WaterLogic

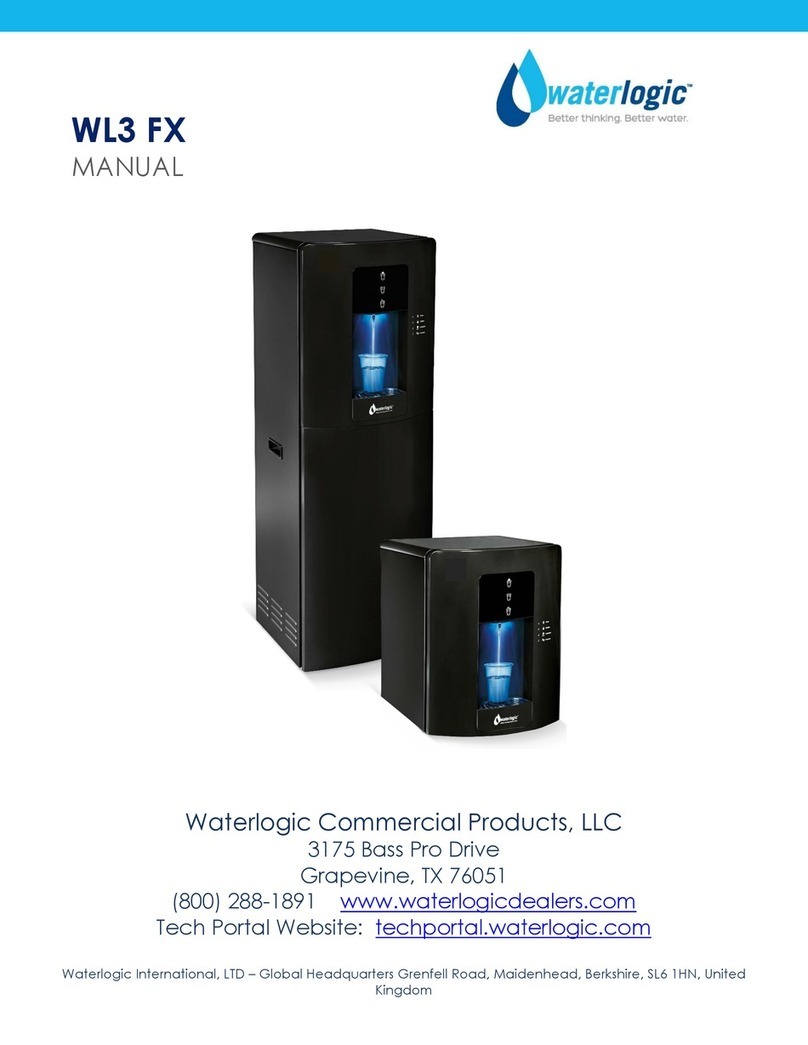

WaterLogic WL3 FX User manual

WaterLogic

WaterLogic WL15-HCS User manual

WaterLogic

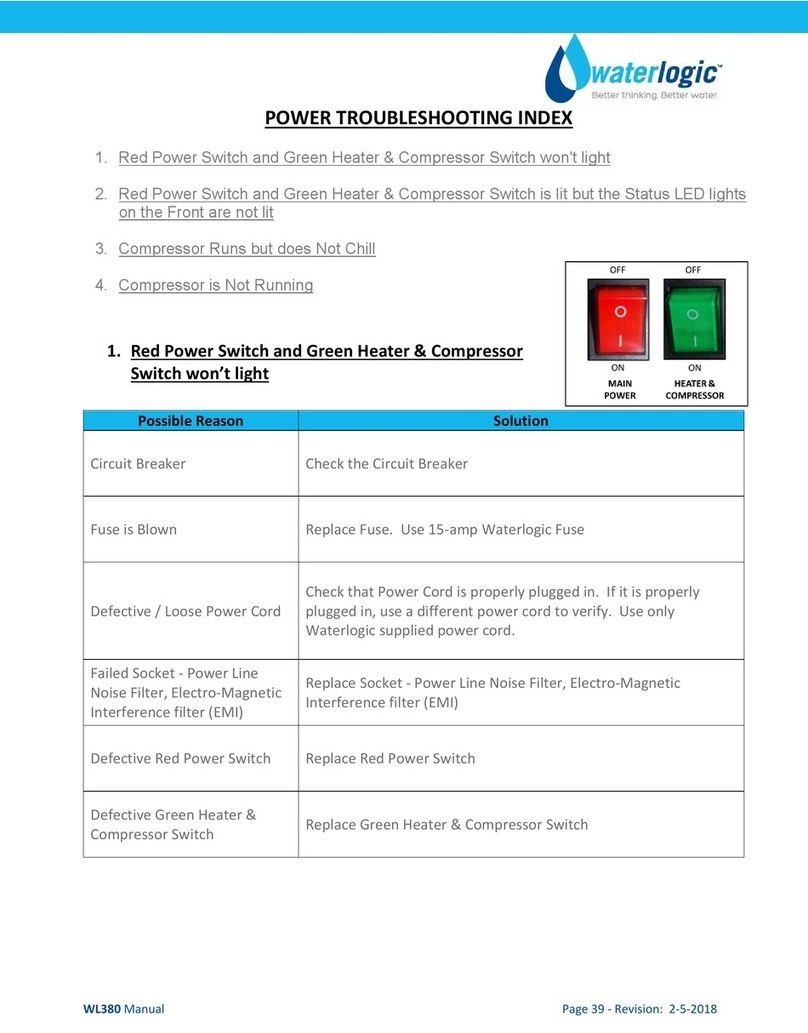

WaterLogic WL380 Operating instructions

WaterLogic

WaterLogic WL2FL FIREWALL User manual

WaterLogic

WaterLogic WL100 Reference guide

WaterLogic

WaterLogic WL270 User manual

WaterLogic

WaterLogic F-FWEG1-M-A-NT Series User manual

WaterLogic

WaterLogic WL7 User manual

WaterLogic

WaterLogic WL100 Operating instructions

WaterLogic

WaterLogic WL100 Operating instructions

WaterLogic

WaterLogic escowa Purus iQ3 User manual

WaterLogic

WaterLogic WL380 User manual

WaterLogic

WaterLogic WL2FLT User manual

WaterLogic

WaterLogic WL15 User manual

WaterLogic

WaterLogic WL500 - Sparkling User manual

WaterLogic

WaterLogic WLH2 Classe Operating and maintenance manual

WaterLogic

WaterLogic PUREZZA WL2FL FIREWALL User manual

WaterLogic

WaterLogic WL7 User manual

WaterLogic

WaterLogic WL850HV User manual

WaterLogic

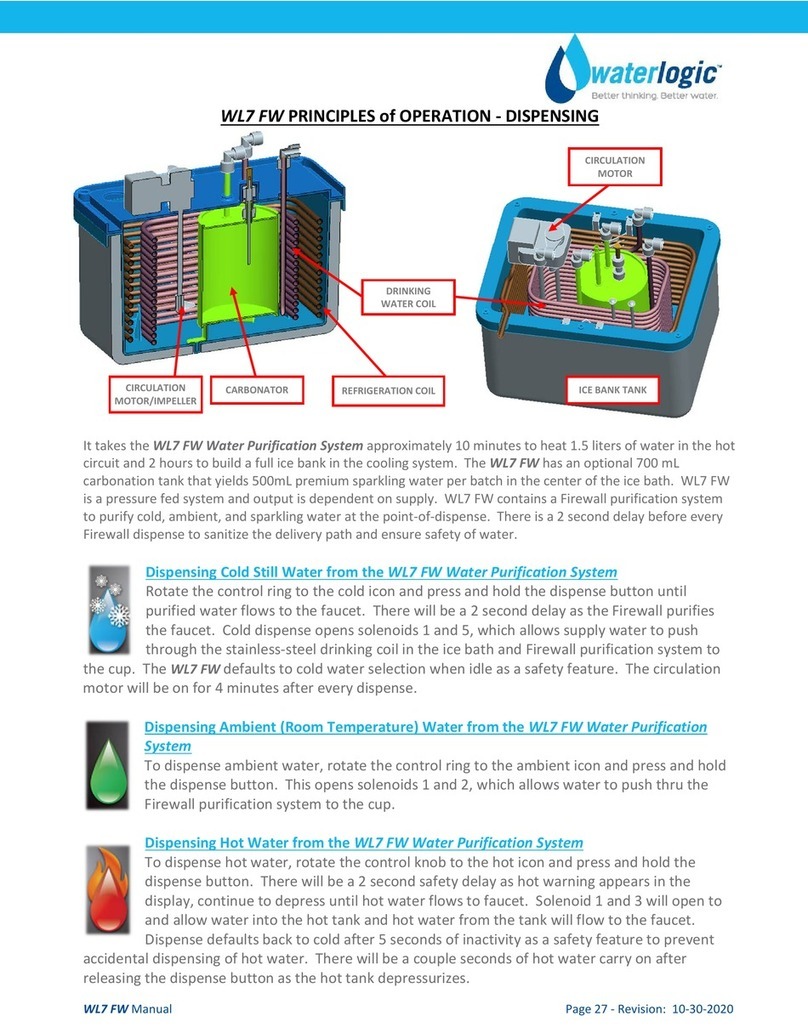

WaterLogic WL7 FW Reference guide

Popular Water Filtration System manuals by other brands

Premier Tech Aqua

Premier Tech Aqua Ecoflo ST-500 owner's manual

Hydac

Hydac CSI-C-11 Operating instruction

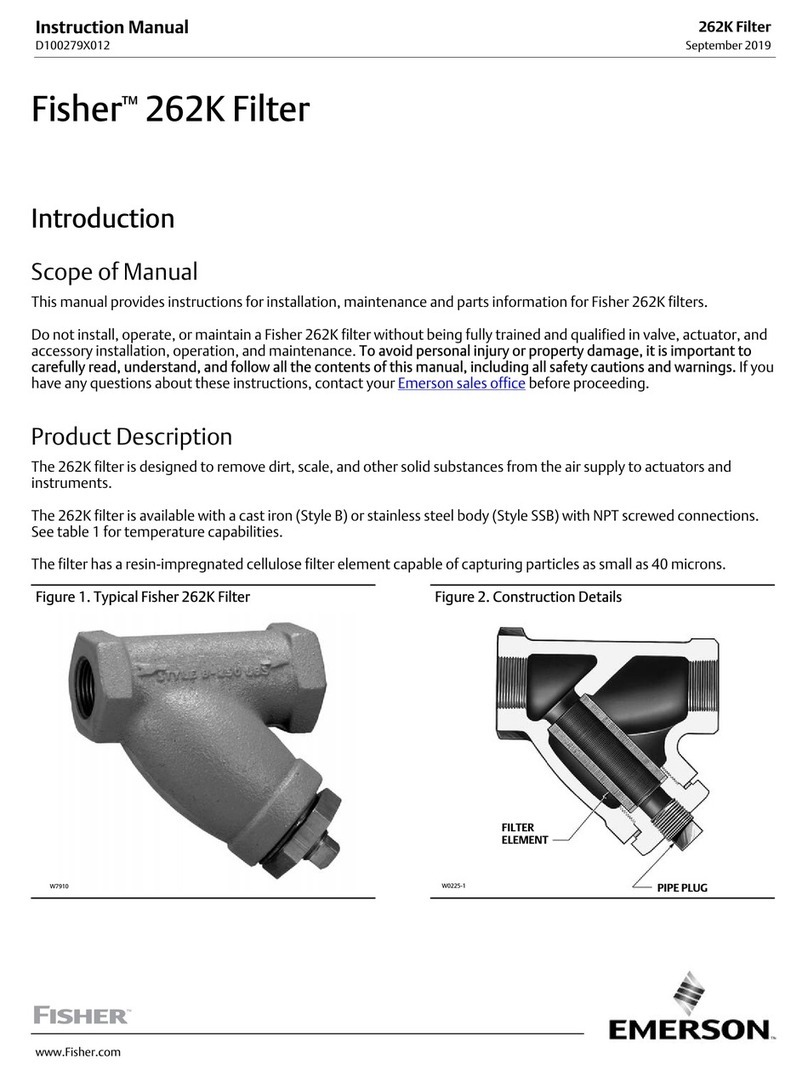

Emerson

Emerson Fisher 262K instruction manual

Kessel

Kessel NS 3 Installation and operating instructions

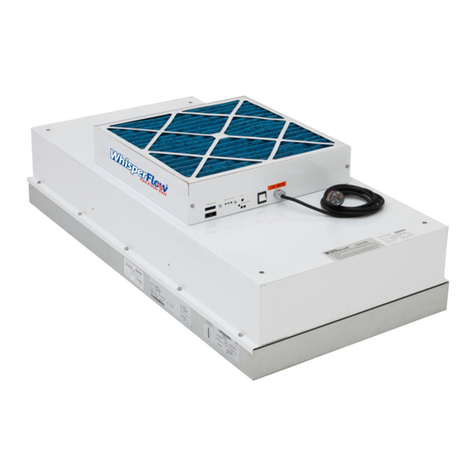

Terra Universal

Terra Universal WhisperFlow 6601-24A-UR-220 product manual

AZUD

AZUD FBC 103 SW user manual

EHEIM

EHEIM eXperience 350 Important safety instructions

Rx Clear

Rx Clear HydroSalt Installation & operation manual

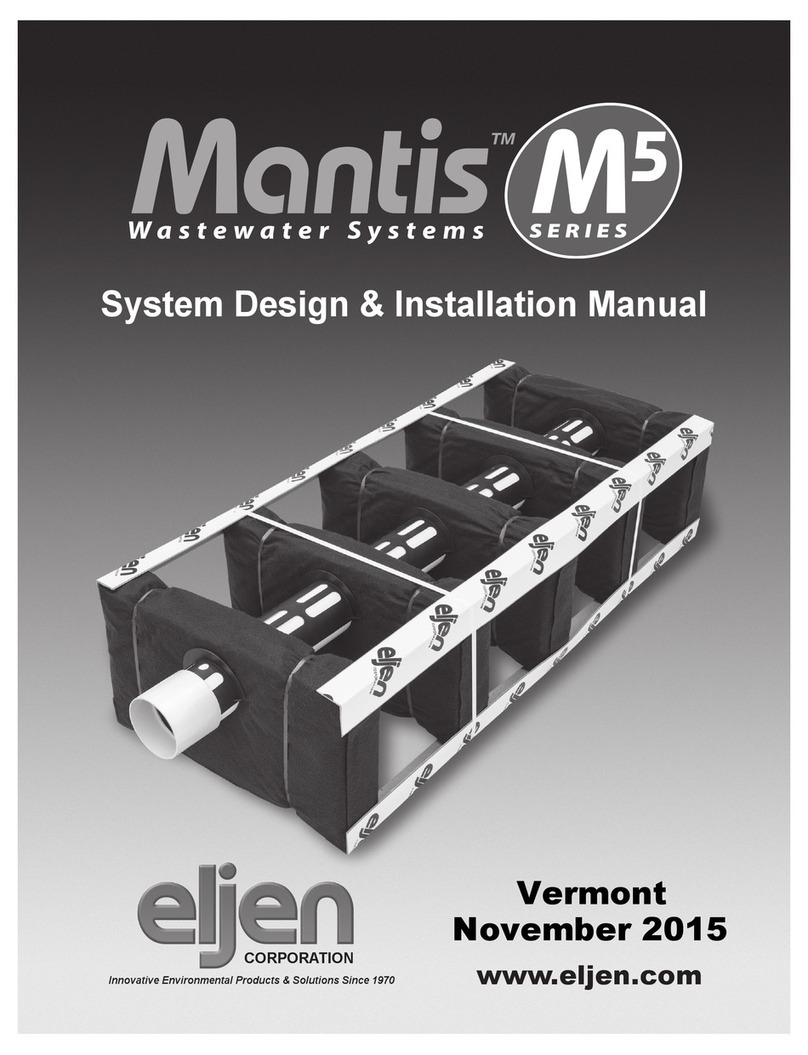

Eljen

Eljen Mantis M5 Series Installation and System Design Guide

Vortec

Vortec THREAD GUARD 424 Operation & Safety Instructions

Carel

Carel ROC025500N user manual

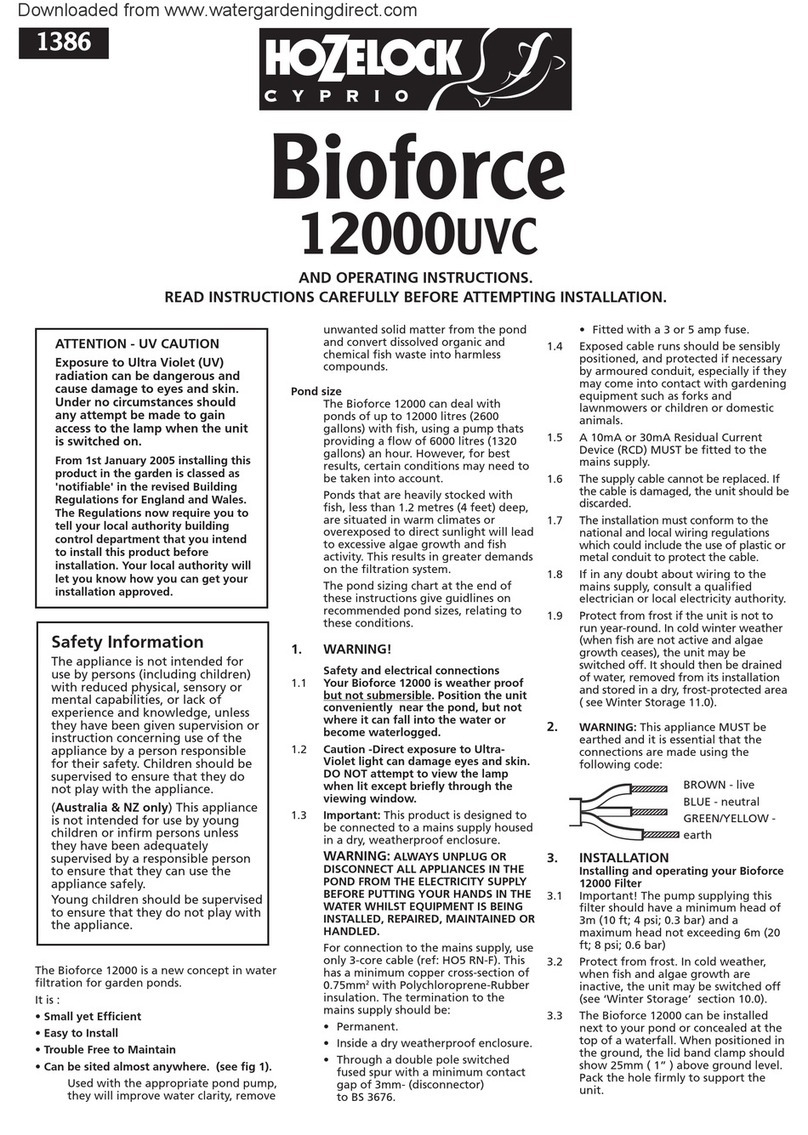

Hozelock

Hozelock bioforce 12000UVC operating instructions