Tab l e 4: E xte rnal R FI filter models for CFW100

WEG Item Name Description

13128410 CFW100-KFABC External RFI filter k it WEG

- - Filter B 84142A0010R000 Epcos (*)

(*) For Electrodiagnostica Radiation Disturbance use choke (T60006- L2016-W403 – VACUUMSCHMELZE).

Tab l e 5: Conducted and radiate d emission levels, and addi tional information

Inverter Model

Conducted Emission – Maximum Motor Cable

Length Radiated Emission

Category C2 Category C3 Category C3

1CFW100A01P6S220

1 m (39 in) 10 m (393 in) 10 m (393 in)

2CF W10 0B 02P6 S2 20

3CFW100C04P2S220

(1) The switching fre quen cy is 5 KHz.

10.4 ACCESSORIES

The accessories are hardware resources that can be added in the application with the CFW100.

The accessories are incorporated to the inverters in an easy and quick way by using the concept “Plug and

Play”. The accessor y must be installed or modified with the inverter de-energized. They may be ordered

separately, and are sent in their own package containing the components and manuals with detailed

instructions for their installation, operation and setting.

11 USE OF THE KEYPAD TO OPERATE THE INVERTER

Selects (toggles)

display betwe en the

parameter number

and its value (position/

content).

Decreases the

frequency, parameter

number or parameter

value.

Increases the

frequency, parameter

number and parameter

value.

Enables/disables the inverter

via acceleration/deceleration

ramp (start/stop, according to

P229). Resets the inve rter a fter

a fault event.

11.1 INDICATIONS OF DISPLAY

Inverter status

Direction of

rotation

Unit of measurement

(it refe rs to the va lue

of the main display)

Bar to monitor

the variable

Main display

11. 2 OPERATING MODES OF THE HMI

Initialization Mode

It is the in itial state of th e HMI after its s uccessfu l power-up (witho ut

the occurrence of faults, alarms or undervoltage).

Press key to go to level 1 of the parameterizatio n mode –

selection of parameters. Pressing any other key al so switches to

parameterization mode.

Monitoring

Parameterization

Leve l1

Parameterization

Level 2

Parameterization Mode

Level 1:

This is the fir st level of the par ameterization mod e. The parameter

number is shown on the main display.

Use keys and to find the desired parameter.

Press key to go to level 2 of the parameter izati on mode -

change of the parameter values.

Level 2:

The parameter value is shown on the main display.

Use keys and to set the new value in the selected

parameter.

Press key to confirm the modi fication (save the new value).

After confirming the modific ation, the HMI returns to l evel 1 of the

parameterization mode .

Figure 7: HMI operating modes

12 START-UP PREPARATION

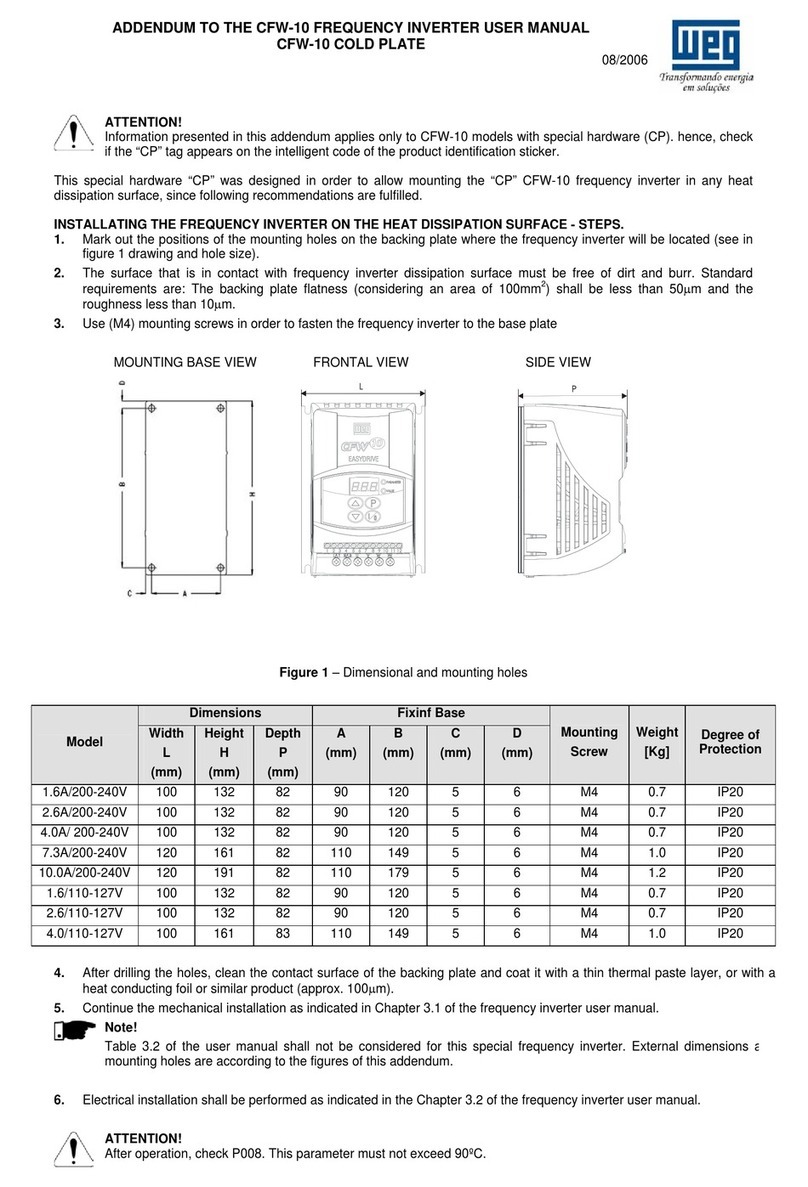

DANGER!

Always disconnect the main power supply before making any connection.

1. Check if the power, grounding and control connections are correct and firm.

2. Remove all the materials left behind from the installation work from inside the inverter or the cabinet.

3. Verif y the motor connections and if its voltage and current are within the inverter rated value.

4. Mechanically uncouple the motor from the load. If the motor cannot be uncoupled, make sure that

any speed direction (forward or reverse) will not result in personnel injury and/or equipment damage.

5. Close the inverter or cabinet covers.

6. Measure the power supply and verify if it is within the allowed range.

7. Apply power to the input: close the input disconnecting switch.

8. Check the result of the first time power-up:

The HMI display indicates:

12 .1 BASIC APPLICATION

The following table contains the basic programming to operate the CFW100 via product HMI:

Seq Display Indication/Action Seq Display Indication/Action

12

Initialization mode.

Press key to enter the first level of the

parameterization mode.

Press keys or to select the parameter P100.

Press key if you ne ed to cha nge the content of

P100 – “Acceleration T ime” or p ress key for the

next parameter.

3 4

If nece ssary, change the content of “ P101 -

Deceleration Time”.

Use key to select the parameter P133.

If nece ssary, change the content of “P133 - Minimu m

Sp e e d ”.

Press key for the next parameter.

5 6

If nece ssary, chan ge the content of “P134 - Max imum

Sp e e d ”.

Press key for the next parameter.

If nece ssary, change the co ntent of “P135 - Output

Maximum Current”.

Press key to select parameter P0 02.

7 8

Press key to view the parameter c ontent. Press key that th e motor will accelerate up to

3.0 Hz (factory default setting of P133 - Minimum

Freq uency).

Press and hold it until it reaches 60.0 Hz.

910

Press key . The motor will d ecelerate to a stop. When the motor stops, the display will indicate

“r e ady”.

12. 2 TYPE OF CONTROL V/f (P202 = 0)

Seq Display Indication/Action Seq Display Indication/Action

12

Initialization mode.

Press key to enter the first level of the

parameterization mode.

Press keys or to select paramete r P202.

34

Press key if you need to change the content of

“P202 – Type of Co ntrol” for P202 = 0 ( V/f).

Pres s key to select paramete r P401.

If nece ssary, change the content of parameter “P401

– Motor Rate d Current” according to the nameplate.

Press key for the next parameter.

56

If nece ssary, change the co ntent of “P402 - Motor

Rated Speed”.

Press key for the next parameter.

If nece ssary, change the co ntent of “P403 - Motor

Rated Frequency”.

13 TECHNICAL SPECIFICATIONS

PO WER DATA

Power Supply:

Tolerance: -15 % to +10 %.

Frequency: 50/60 Hz (48 Hz to 62 Hz).

Phase imbalance: ≤ 3 % of the rated phase-to-phase input voltage.

Over voltage according to Category III (EM 61010/UL 508C).

Transient voltages according to Category III.

Maximum of 10 connections per hour (1 every 6 minutes).

Typical efficiency: ≥ 97 %.

14 ELECTRONICS/GENERAL DATA

Table 6: Electronics/general data

Control Method Types of control:

- V/f (Scalar)

- VVW: voltage vector control

PWM SVM (Space Vector Modulation)

Output frequency 0 to 300 Hz, re solution of 0.1 Hz

Performance V/f Control Speed reg ulation: 1 % of the rated spe ed (with slip compensation)

Speed variation range: 1:20

Vector control ( V V W) Speed regulation: 1 % of the rated s peed

Speed variation range: 1:30

Inputs Digital 4 isolated inputs

Maximum input vol tage of 30 Vdc

Input current: - 11 mA

Maximum input current: -20 m A

Safety Protection Output overcurrent/short-circuit

Under/overvoltage

Motor overload

Over temperature in the power module (IGBTs)

Fault / ex ternal alarm

Programming error

Integral keypad

(HMI)

Standard keypad 4 keys: Start/Stop, Up arrow, Down ar row and Programming

LCD Display

View/edition of parameters

Indication accuracy:

- current: 5 % of the rated current

- speed resolution: 0.1 Hz

Enclosure IP20 Frame Sizes A, B and C

15 CONSIDERED STANDARDS

Tab l e 7: Considered standards

Safety

standards

UL 508C - power conversion equipme nt

UL 840 - insulation coordination including clearances and creepage distances for electrical

equipment

EN61800-5-1 - safety requirements electrical, thermal and energy

EN 50178 - electron ic equipment for use in power installations

EN 60204-1 - safety of machine ry. Electrical equipment of machines. Part 1: general re quirements

Note: the final assembler of the machine is responsible for installing a safety stop device and a

supply disconnecting device

EN 60146 (IEC 146) - semiconductor converters

EN 61800-2 - adjusta ble speed el ectrical power drive syste ms - Part 2: gene ral require ments - rating

specifications for low voltage adjustable frequency AC power drive systems

Mechanical

standards

EN 60529 - degree s of protection provided by enclosures (IP code)

UL 50 - enclosures for electrical equipment

Electromagnetic

compatibility

(EMC)

standards (*)

EN 61800-3 - adjustable speed electrical power dr ive systems - part 3: EMC product standard

including specific test methods

EN 55011 - limits and methods of measurem ent of radio disturbance characteristics of industrial,

scientific and medical (ISM) radio-frequency equipment

CISPR 11 - industrial, scientific and medical (ISM) radio-frequency equipme nt - electromagnetic

disturbanc e characteristic s - limits and methods of measu rement

EN 61000-4-2 - electromagnetic compatibility (EMC)- par t 4: testing and measurement techniques

- section 2: electrostatic discharge immunity test

EN 61000-4-3 - electromagneti c compatibil ity (EMC) - par t 4: testin g and measure ment techniques

- section 3: radiated, radio-frequency, electromagnetic field immunity test

EN 61000-4-4 - ele ctromagneti c compatibil ity (EMC) - par t 4: testing and measure ment techniques

- section 4: electrical fast transient/burst immunity test.

EN 61000-4-5 - ele ctromagneti c compatibil ity (EMC) - par t 4: testin g and measure ment techniques

- section 5: surge immun ity test.

EN 61000-4-6 - ele ctromagnetic comp atibility (EMC) - par t 4: testing and me asurement te chniques

- section 6: immu nity to condu cted disturb ance s, indu ced by radio-frequency fields.

(*) Stand ards met with th e installati on of the external RFI filter. For fur ther details refer to www.weg.net.

16 MAIN PAREMETERS

The table below contains the mains parameters of the CFW100.

NOTE!

ro = read only parameter.

V/f = parameter available in V/f mode.

cfg = configuration parameter, value can only be changed with the motor stopped.

Param. Description Adjustable Range Factory Setting Prop.

P000 Access to Parameters 0 to 9999 1

P001 Speed Reference 0 to 9999 ro

P002 Output Speed (Motor) 0 to 9999 ro

P003 Motor Current 0.0 to 10.0 A ro

P004 DC Lin k Voltage (Ud) 0 to 524 V ro

P005 Output Frequency (Motor) 0.0 to 300.0 Hz ro

P006 Inverter Status 0 = Ready

1 = Run

2 = Undervoltage

3 = Fault

4 = Not Used

5 = Configuration

ro

P007 Output Voltage 0 to 240 V ro

P0 11 Active Current -10.0 to 10.0 A ro

P012 DI 8 to DI1 Status 0 to FF (hexa)

Bit 0 = DI1

Bit 1 = DI2

Bit 2 = DI3

Bit 3 = DI4

Bit 4 = DI5

Bit 5 = DI6

Bit 6 = DI7

Bit 7 = DI8

ro

P022 FI Value in Hz 1 to 30 00 Hz ro

P023 Main SW Version 0.00 to 99.99 ro

P030 Module Temperature -200.0 to 200.0 ºC ro

P037 Motor O verload Ixt 0.0 to 100.0 % ro

P047 CONFIG Status 0 to 999 ro

P048 Present Alarm 0 to 999 ro

P049 Present Fault 0 to 999 ro

P050 Last Fault 0 to 999 ro

P100 Acceleration Time 0.1 to 999.9 s 5.0

P101 Deceleration Time 0.1 to 999.9 s 10.0

P120 Speed Ref. Backup 0 = Inactive

1 = Active

2 = Backu p by P121

1

P121 Referenc e via HM I 0.0 to 300.0 Hz 3.0 Hz

P124 Multisp eed Ref. 1 -300.0 to 300.0 Hz 3.0 Hz

P125 Multispeed Ref. 2 -300.0 to 300.0 Hz 10.0 (5.0) Hz

P126 Multispeed Ref. 3 -300.0 to 300.0 Hz 20.0 (10.0) Hz

P127 Multispeed Ref. 4 -300.0 to 300.0 Hz 30.0 (20.0) Hz

P128 Multispeed Ref. 5 -300.0 to 300.0 Hz 40.0 (30.0) Hz

P129 Multispeed Ref. 6 -300.0 to 300.0 Hz 50.0 (40.0) Hz

P130 Multispeed Ref. 7 -300.0 to 300.0 Hz 60.0 (50.0) Hz

P131 Multispe ed Ref. 8 -300.0 to 300.0 Hz 66.0 (55.0) Hz

P133 Minimum Frequency 0.0 to 300.0 Hz 3.0 Hz

P134 Maximum Frequency 0.0 to 300.0 Hz 66.0 (55.0) Hz

P135 Maximum Output Current 0.0 to 10.0 A 1.5xI nom

P136 Manual Torque Boost 0.0 to 30.0 % 0.0 % V/f

P137 Automatic Torque Boost 0.0 to 30.0 % 0.0 % V/f

P138 Slip Compensation -10.0 to 10.0 % 0.0 % V/f

P139 Output Current Filter 0 to 9.999 s 0.005 s

P140 Slip Com. Filter 0 to 9.999 s 0.5 s VVW

P142 Maximum Output Voltage 0.0 to 100.0 % 100.0 % cf g, V/f

P143 Intermediate Output

Voltage

0.0 to 100.0 % 50.0 % cfg, V/f

P145 Field Weakening Start

Frequency

0.0 to 300.0 Hz 60.0 (50.0) Hz c fg, V/f

P146 Intermediate Frequency 0.0 to 300.0 Hz 30.0 (25.0) Hz cfg, V/f

P156 Overload Current 0.1 to 2xInom 1.2xInom

P202 Type of Control 0 = V/f

1 = V/f Quadratic

2 to 4 = Not Used

5 = V V W

0cfg

P204 Load/Save Parameters 0 to 4 = Not Used

5 = Load 60 Hz

6 = Load 50 Hz

7 = Load Use r

8 = Not Used

9 = Save User

10 = Not Used

11 = Load Default SoftPLC

12 to 13 = Reserved

0cfg

P220 LOC/REM Selection

Source

0 = Always Local

1 = Always Remote

2 to 3 = Not Used

4 = DIx

5 = Serial/USB (LOC)

6 = Serial/USB (REM)

7 to 8 = Not Used

9 = CO/DN (LOC)

10 = CO/DN (REM)

11 = SoftPLC

0 cfg

P221 LOC Reference Sel. 0 = HMI Keys

1 = AI1

2 to 3 = Not Used

4 = FI

5 to 6 = Not Used

7 = E.P.

8 = Multispeed

9 = Serial/USB

10 = Not Used

11 = CO/DN

12 = SoftPLC

13 = Not Used

14 = AI1 > 0

15 to 16 = Not Used

17 = FI > 0

0 cfg

Param. Description Adjustable Range Factory Setting Prop.

P222 REM Reference S el. See option s in P221 2 cfg

P223 LOC Rotation Sel. 0 = Al ways FWD

1 = Always R EV

2 = Not Used

3 = Not Used

4 = DIx

5 = Serial/USB (FWD)

6 = Serial/USB (REV)

7 to 8 = Not Used

9 = CO/DN (F WD)

10 = CO/DN (RE V)

11 = Not Used

12 = SoftPLC

0cfg

P263 DI1 Input Function 0 = Not Used

1 = Run/Stop

2 = General Ena ble

3 = Quick Stop

4 = Forward Run

5 = Reverse Run

6 = Star t

7 = Stop

8 = FWD/R EV

9 = LOC/REM

10 = JOG

11 = Increase E.P.

12 = Decelerate E.P.

13 = Multispeed

14 = 2nd Ramp

15 to 17 = Not Used

18 = No Ext. Alarm

19 = No Ext. Fault

20 = Reset

21 to 23 = Not Used

24 = Disab. Flying Start

25 = Regul. DC Link

26 = Lock Pro g.

27 to 31 = Not Used

32 = 2nd Ramp Multispeed

33 = 2nd Ramp E.P. Ac.

34 = 2nd Ramp E.P. De.

35 = 2nd Ramp FRW Run

36 = 2nd Ramp R ev Run

37 = Turn ON / Ac. E.P.

38 = De. E.P. / Turn OFF

39 = Stop

40 = Safet y Switch

41 = Function 1 Application

42 = Function 2 Application

43 = Function 3 Application

44 = Function 4 Application

45 = Function 5 Application

46 = Function 6 Application

47 = Function 7 Application

48 = Function 8 Application

1cfg

P264 DI2 Input Function See options in P263 8 cfg

P265 DI3 Input Function See options in P263 0 cfg

P266 DI4 Input Function Se e options in P263 0 cfg

P295 Inv. Rated Current 1.6 to 15.2 A According to

inverter model

ro

P296 Line Rated Voltage 0 to 1 = Re ser ved

2 = 200 - 240 V

2 ro, cfg

P297 Switching Frequency 2.5 to 15.0 kHz 5.0 kHz

P401 Motor R ated Current 0.0 to 10.0 A 1.4 A cfg

P402 Motor Rated Speed 0 to 9999 rpm 1720 (1310) rpm cfg

P403 Motor Rated Frequency 0 to 300 Hz 60 (50) Hz cfg

17 FAULTS AND ALARMS

Most common faults and alarms

Fault / Alarm Description Possible Causes

A046

Motor Overload

Motor overload alarm Settings of P156 is too low for the used motor

Overl oad on th e motor sh aft

A050

Power Module

Overtemperature

Overtemperature alarm from the

power module temperature sensor

(NTC)

High temperature at IG BTs (P030 > 110 °C)

High ambient temperature around the inve rter (>50 °C (>

122 °F)) and hi gh output cur rent

Blocked or defective fan

Heatsink is too dirt y, preventing the air flow

A090

External Alarm

Exte rnal a larm v ia DIx (option “N o

Exte rnal A larm” in P26x)

Wiring on DI1 to DI4 inputs are open or have poor contact

A700

Remote HMI

Communication Fault

No communication with remote HMI,

but here is frequency command or

refere nce for this source

Check if the communication interface with the HMI is

properly configured in parameter P312

HMI cable disconnected

F021

Undervoltage on the

DC Link

Undervoltage fault on the intermediate

circuit

Wrong voltage supply; check if the data on the inverter

label comply with the power supply and parameter P296

Suppl y voltage too low, pro ducing voltage on the DC link

below the minimum value (in P004):

Ud < 200 Vdc in 200 / 240 Vac

Phase fault in the inpu t

Fault in the pre-charge circuit

F022

Overvoltage on the

DC Link

Overvoltage fault on the intermediate

circuit

Wrong voltage supply; check if the data on the inverter

label comply with the power supply and parameter P296

Supply voltage is too high, producing voltage on the DC

link above the ma ximum valu e (in P0 04):

Ud > 410 Vdc in 200 / 240 Vac

Load inertia is too high or deceleration ramp is too fast

P151 setting is too high

F031

Fault of

communication with

the accessory

Main control cannot e stablish the

communication link with accessory

Accessory damaged

Poor connection of the accessory

Proble m in the identi fication of th e accessor y; refer to P027

F051

IG B Ts

Overtemperatures

Overtemperature fault measured

on the temperature sensor of the

power pack

High temperature at IG BTs (P030 > 120 °C)

High ambient temperature a round the inverter (>50 °C

(>122 °F)) and high output current

Blocked or defective fan

Heatsink is too dirt y, preventing the air flow

F070

Overcurrent/

Shortcircuit

Overcurrent or short-circuit on the

output, DC link o r brak ing resistor

Short-circuit between two motor phases

IGBTs module in short-circuit or damaged

Star t with too shor t acceleration ramp

Start with motor spinning without the Flying Start function

F072

Motor Overload

Motor overload fault

(60 s in 1.5 x Inom)

P156 setting is too low in relation to the motor operating

current

Overl oad on th e motor sh aft

F080

CPU Fault

(Watchdog)

Fault related to the supervision

algor ithm of the inverter main CPU

Electric noise

Inverter firmware fault

F081

Fault on the Save

User function

Fault in the attempt to save the user

parameter table

Attempt to save (P20 4 = 9) more than 32 paramete rs

(with values diffe rent from the factory defau lt) on the User

parameter table

The function Saves User is blocked

F082

Fault in the Copy

Function (MMF)

Fault in the copy of parameters Attempt to c opy the parameters from the Fl ash Me mor y

Modul e to the inve rter with different sof twa re vers ions

F084

Auto-diagnosis

Fault

Fault related to the automatic

identification algorithm of the inverter

hardware

Poor contact in the connection between the main control

anthe power pac k

Hardware not compatible with the firmware version

Defect on the internal circuits of the i nver ter

F091

External Fault

Exte rnal fault via DIx (“No Ex ternal

Fault” in P26x)

Wiring on DI1 to DI4 inputs are open or have poor contact

F701

Remote HMI

communication fault

No communication with the remote

HMI; however, there is command or

frequ ency reference for th is source

Check that the HMI communication interface is properly

configured in para meter P312

HMI cable disconnected

NOTE!

For further information, refer www.weg.net.

Document: 10003540581 / 00