ASSEMBLY

Make Assembly Easier

Evewthing in this manual is designedto

ensure that the weight system can be assem-

bledsuccessfullybyartjone.

Before beginning assembly, makoosureto

read the information on this page. This

brief Introduction will me you much more

time than It takeS to read it.

Assembly Requires Two Persons

For your convenienceand safety,assemble the

weight systemwith the helpof anotherperson.

Set Aside Enough Time

Due tothe many features ofthe weightsystem, the

assembly process will requireseveral hours. By

settingaside plentyof time and bydecidingto

make the task enjoyable, assemblywillgo smoothly.

Select a Location for the Weight System

Because of _tsweight and size, the weightsystem

shouldbe assembled in the locationwhere it wdlbe

used. Make sure thatthere isenough roomto walk

around theweight systemas you assemble it.

How to Unpack the Box

To make assembly easier,we have divided the

assembly process intofourstages. The small hard-

ware needed for each stage is packaged in sepa-

rate bags. Important: Wait until you begin each

stage to open the parts bag(s) for that stage.

Place all partsof the weight system in a cleared

area and remove the packing materials.Do not dis-

pose ofthe packingmatarialsuntJIassemblyiscom-

pleted

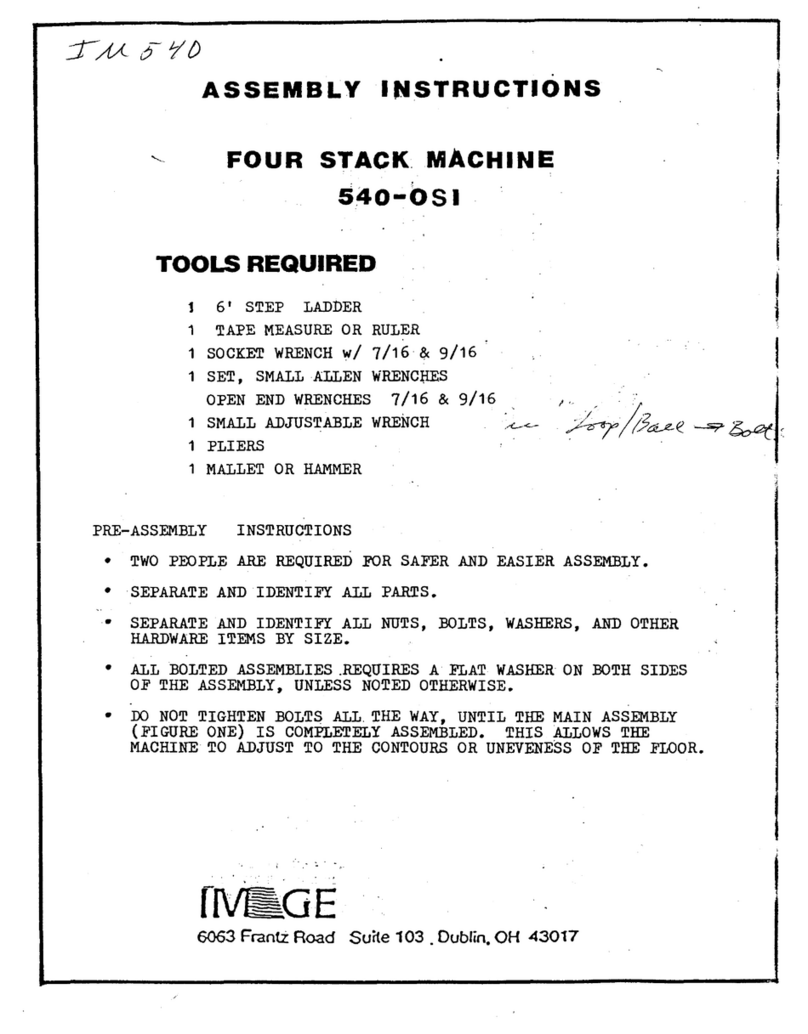

Make sure that you have the following tools:

• Two adjustablewrenches

• One standard scrawddver

•One philhpsscrewdriver

• One rubber mallet

•You w=llalso need grease or petroleumjelly, a

small amount ofsoapy water, and maskingtape

Note:Assemblywillbe more convenientifyou have

a socket set, a set ofopen-end or closed-end

wrenches, or a set ofratchet wrenches.

How to Identify Parts

To help you identify the small parts used in assembly,

a PART IDENTIFICATION CHART is included in the

center ofthis manual. Laythe charton the floorand

use it to easily identifyparts dudngeach assembly

step. Note: Some small parts may have been pre-

attached. If a part is not in the parts bag, check

to see if it has been pre-attached.

How to Orient Parts

As you assemble the weightsystem, make sure that

all parts are orientedexactly as shownin the draw-

rags.

Tightening Parts

Tighten all parts as you assemble them, unless

instructedto do otherwise.

Questions?

Ifyou have questionsafter readingthe assembly

instructions,please call our Customer Service

Departmenttoll-free at 1-800-736-6879, Monday

through Fdday,6 a.m. until6 p.m. MountainTime.

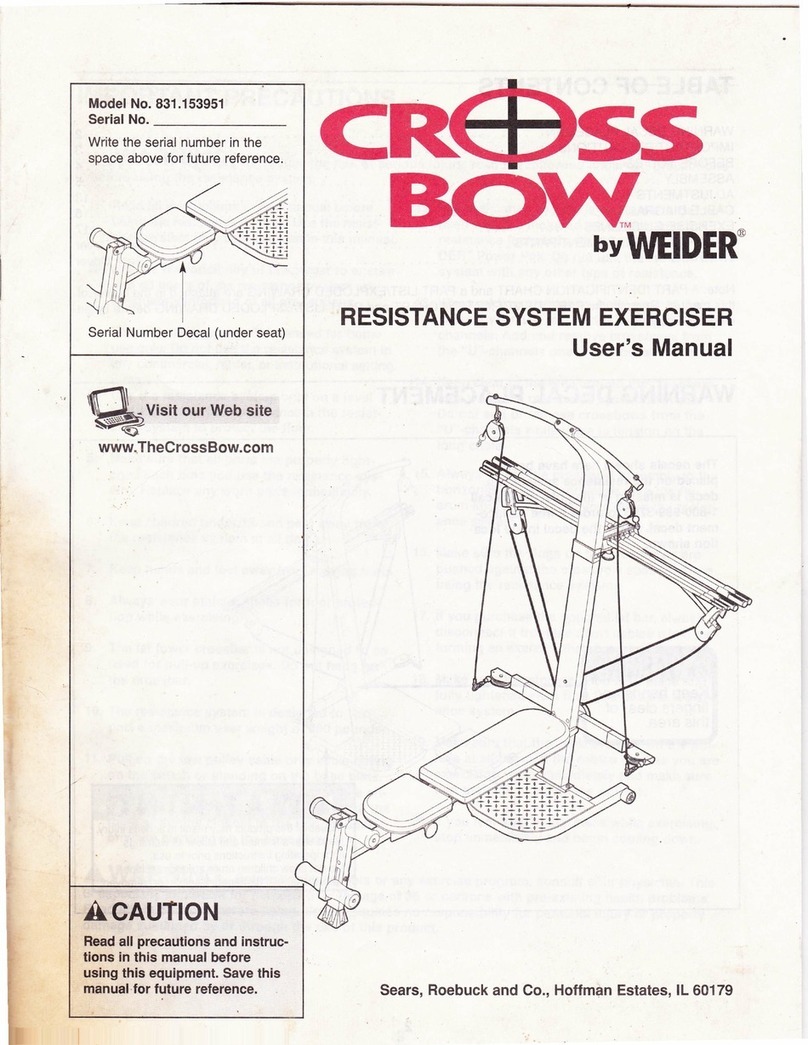

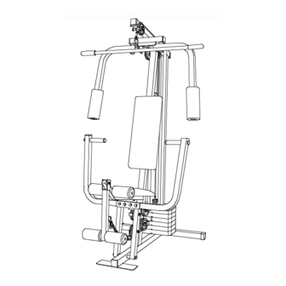

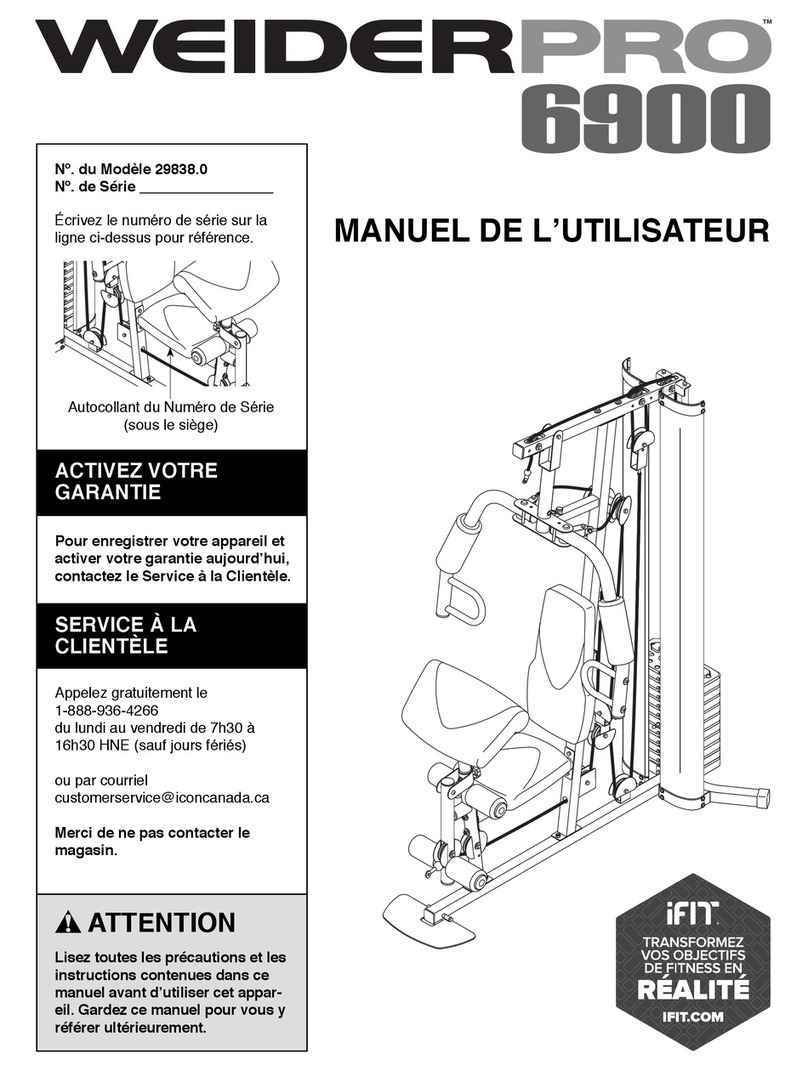

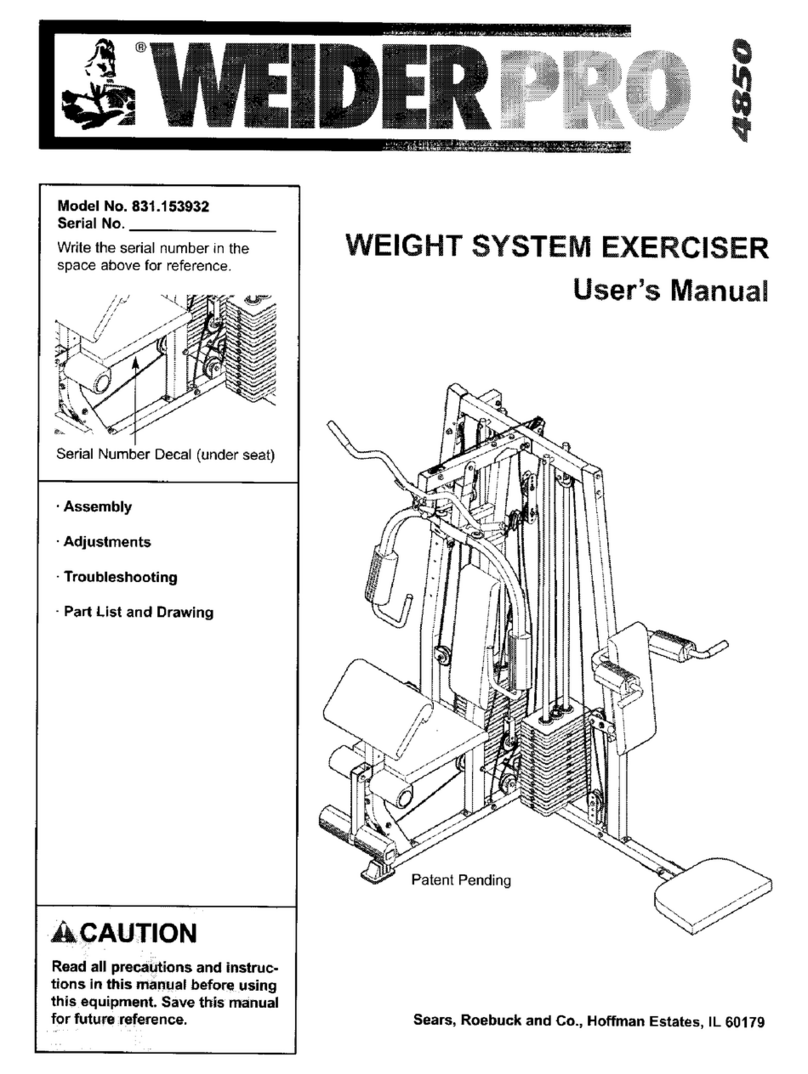

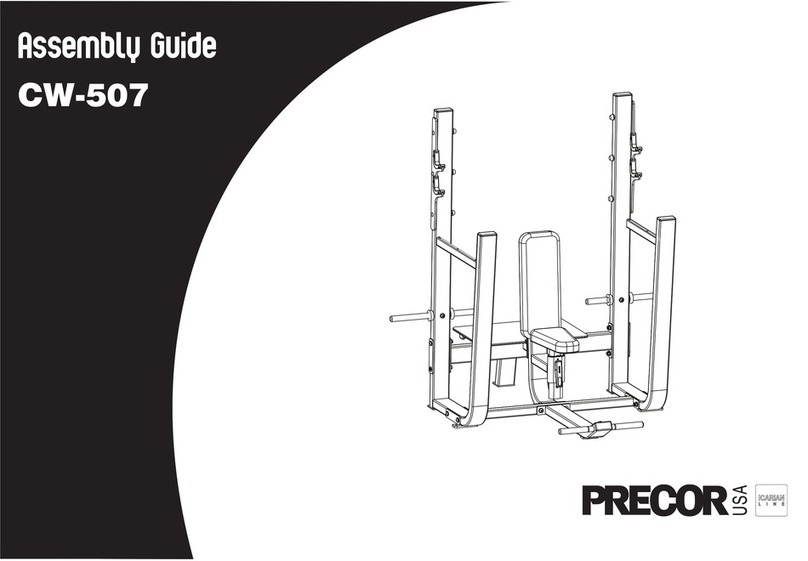

The Four Stages of the Assembly Process

Frame Assembly--You willbegin by assembling

the base and the updghtsthat form the skeletonof

the weight system

Arm Assembly--Dunng this stage, you will

assemble the arms and the leg lever.

Cable Assembly--Dudng this stage, you will

attach the cables and pulleysthatconnectthe

weightstationsto the weight stacks.

Seat Assembly--Dudng the final stage, you will

assemble the seat and the backrests.

5