FORWARD

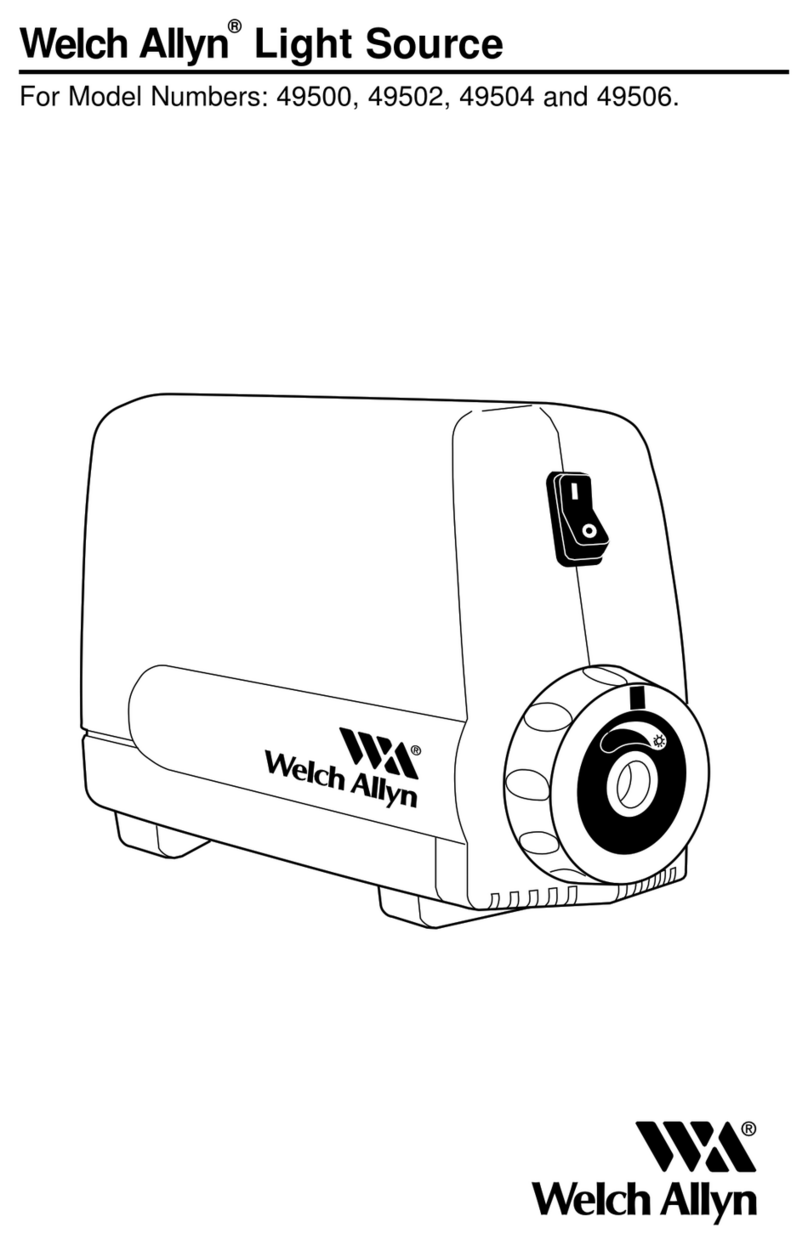

This SERVICE MANUAL provides technical assistance to Welch

Allyn repair technicians for diagnosing, repairing, and testing

the WELCH ALLYN LS100 HALOGEN LIGHT. The manual's main content

areas cover: troubleshooting, step by step repair, adjustment, and

re-test procedures. The repair 'TASK' procedures (R & R ..

Removal and Replacement) are written to provide quick and easy

reference for repair technicians of different experience levels.

Required specifications and materials are listed at each step

where applicable. When reading this manual for the first time,

have an LS100 readily available for reference and practice. Read

each complete repair step on what to do (task statement), plus how

to do it (technique statement) before starting the repair or

practice.

Training for the LS100 should consist of detailed

demonstrations of required repair tasks, practice on LS100'S using

repair tooling and materials. Assess skill development through

observation of trainee practice on actual equipment. Set up

sessions to allow the trainee to practice the use of the

diagnostic, repair, adjustment, and re-testing procedures found in

this manual. The ability of the technician to develop and retain

new skills is in great part dependent on well prepared training

exercises. Each trainee must have the opportunity to practice the

procedure(s) after it has been demonstrated by the instructor.

More detailed background product information is found in the

APPENDIX section and as such will be a critical element in a

comprehensive service training program for technicians.

I M P O R T A N T :

Welch Allyn part numbers and 'M' (material) numbers appearing

in this manual are for the purpose of familiarizing new

technicians with Welch Allyn documentation conventions. Order

replacement parts, as always, by referencing your latest bill of

materials, parts catalog and assembly drawings. Part number

changes, product updates, or new test procedures should be noted

on the appropriate page of this manual by the manual owner.

Notices announcing these changes should be attached to PRODUCT

UPDATES APPENDIX.

HOW TO FIND CURRENT PART NUMBER INFORMATION:

REFER TO THE MOST RECENT ASSEMBLY DRAWING(S) FOR APPLICATION

INFORMATION ON PARTS, PROCESS, AND MATERIALS. FIND THE CURRENT

PART NUMBERS BY REFERRING TO THE CIRCLED NUMBERS ('BUBBLE'

NUMBERS) ON CURRENT ASSEMBLY DRAWINGS. FIND CORRESPONDING PART

NUMBER ON THE MANUFACTURING OR REPAIR BILL OF MATERIALS.