Welch Allyn LS100 User manual

Other Welch Allyn Lighting Equipment manuals

Welch Allyn

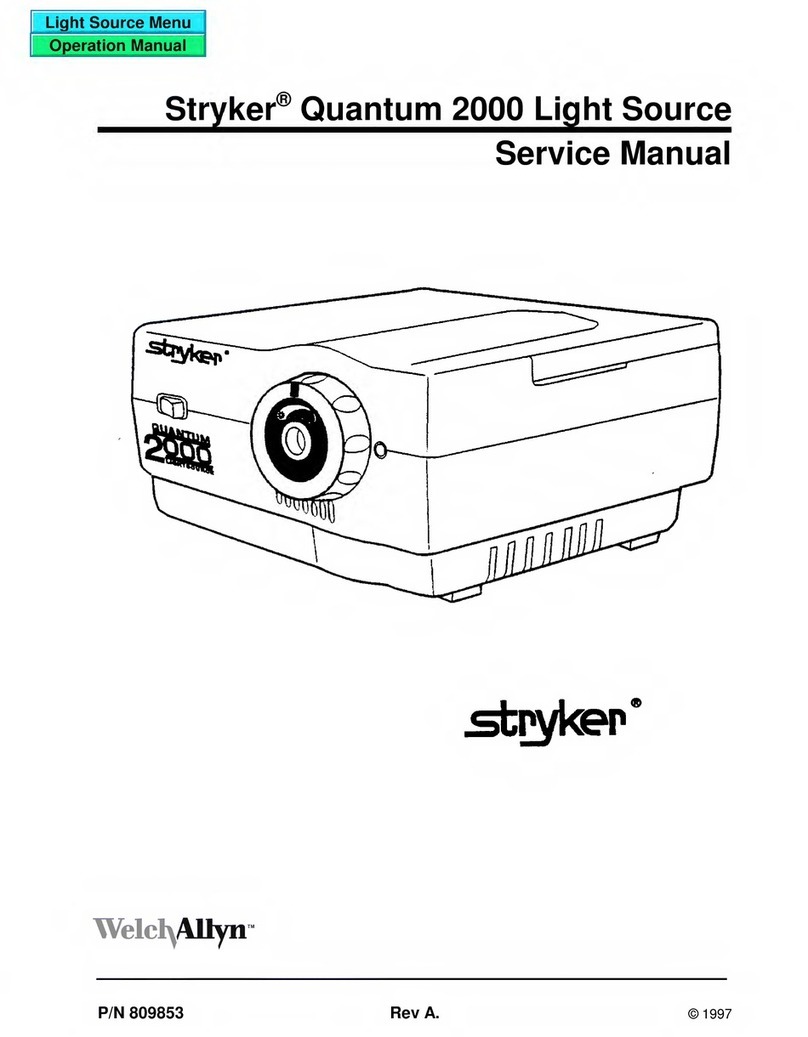

Welch Allyn Stryker Quantum 2000 Light Source User manual

Welch Allyn

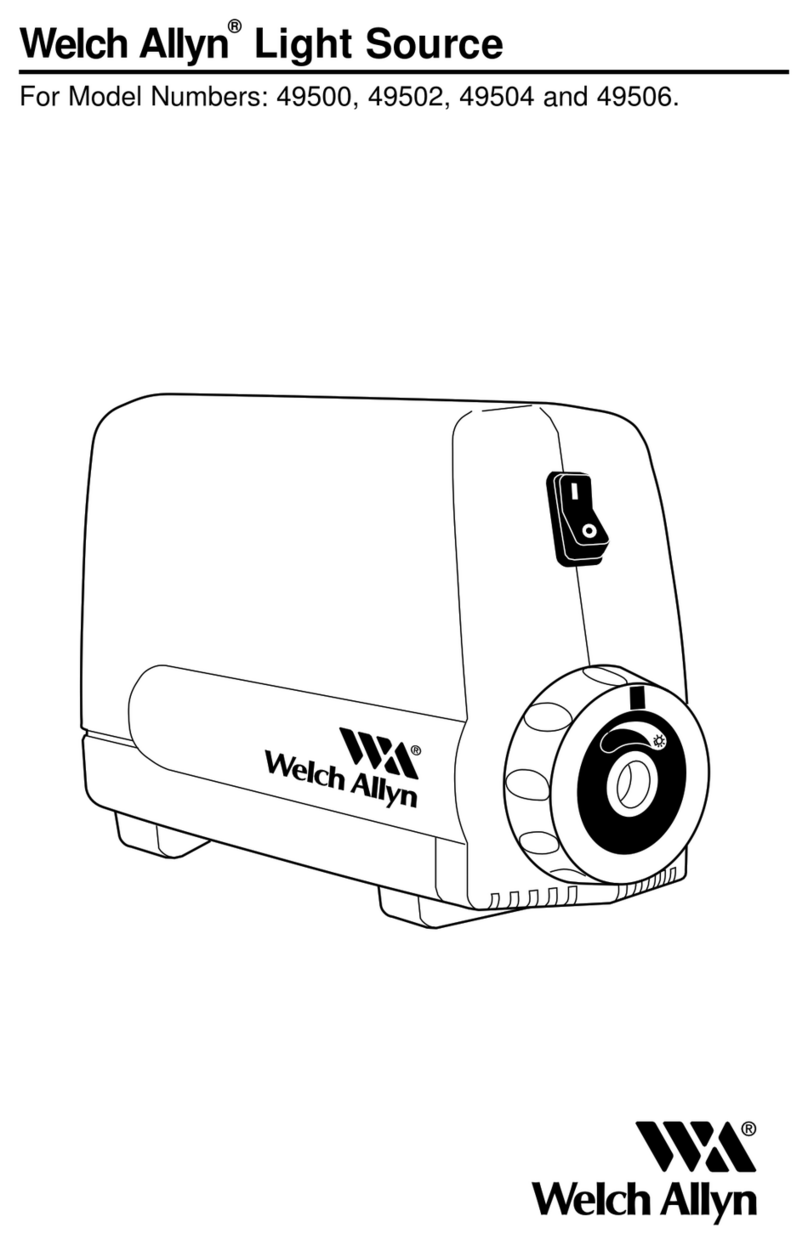

Welch Allyn 49500 User manual

Welch Allyn

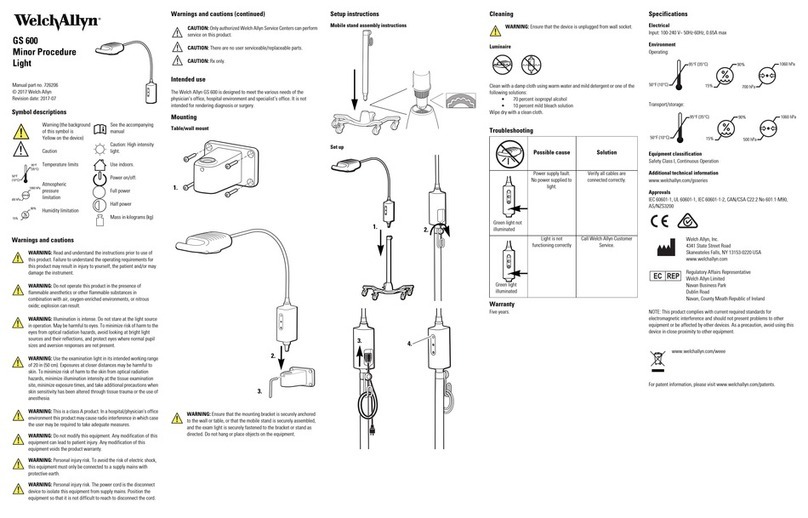

Welch Allyn GS 600 User manual

Welch Allyn

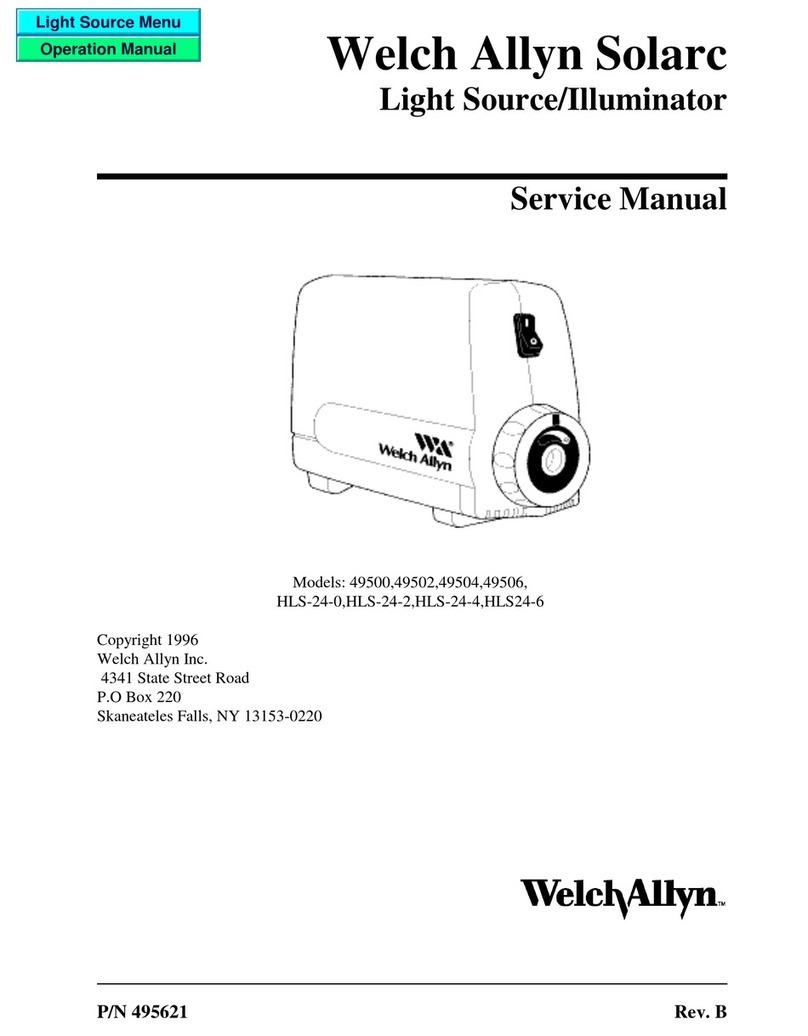

Welch Allyn HLS-24-0 User manual

Welch Allyn

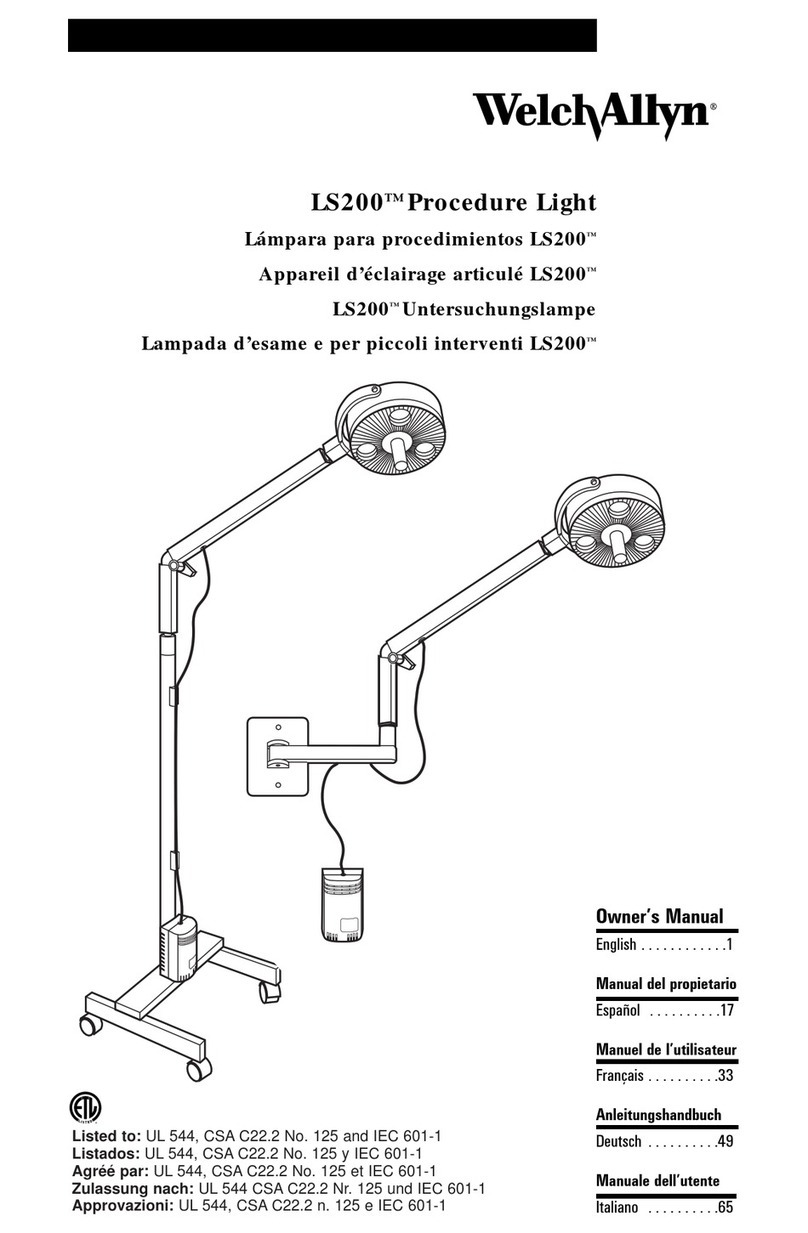

Welch Allyn LS200 Procedure Light User manual

Welch Allyn

Welch Allyn Exam Light III User manual

Welch Allyn

Welch Allyn LS100 User manual

Welch Allyn

Welch Allyn 48700 Instruction Manual

Welch Allyn

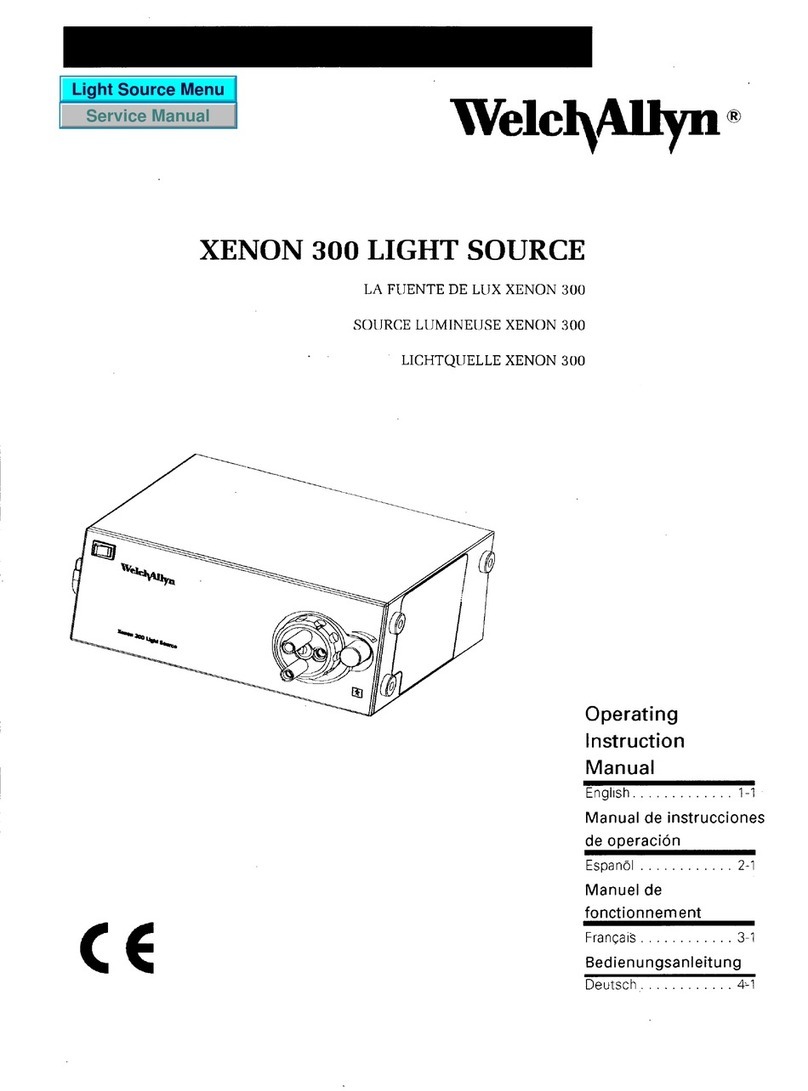

Welch Allyn XENON 300 Instruction Manual

Welch Allyn

Welch Allyn LS100 User manual

Welch Allyn

Welch Allyn KleenSpec 789 Series Manual

Welch Allyn

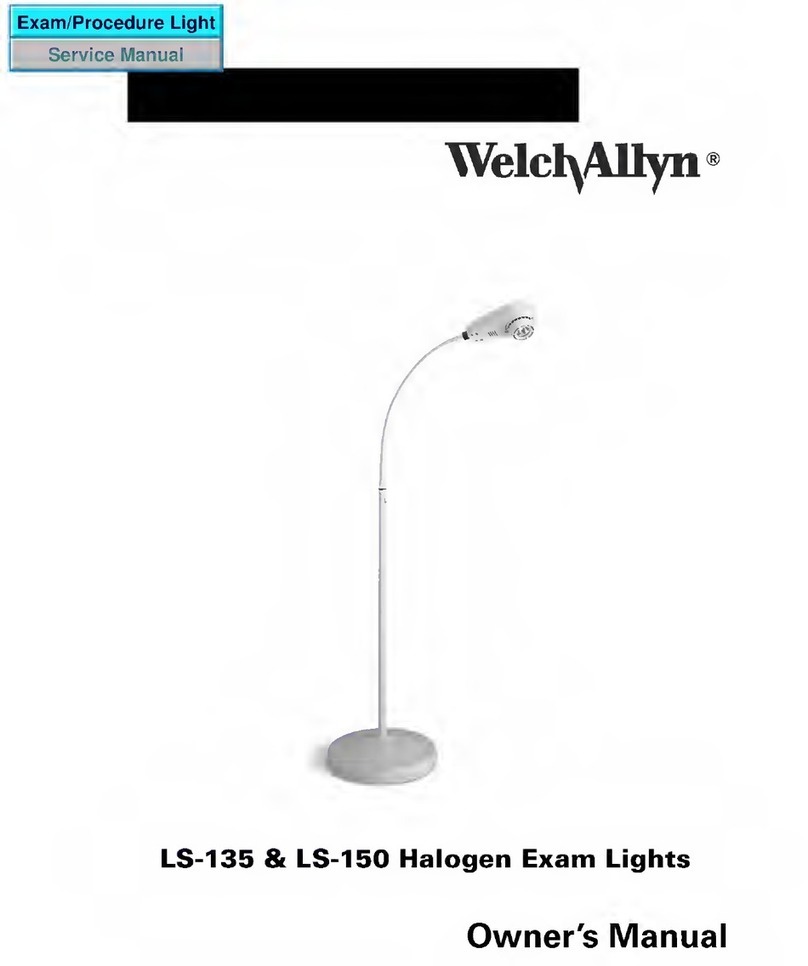

Welch Allyn LS-135 User manual

Welch Allyn

Welch Allyn LS-135 User manual

Welch Allyn

Welch Allyn GS 900 User manual

Welch Allyn

Welch Allyn LS-135 User manual

Welch Allyn

Welch Allyn Solarc M21P011 User manual

Welch Allyn

Welch Allyn LS200 Procedure Light User manual

Welch Allyn

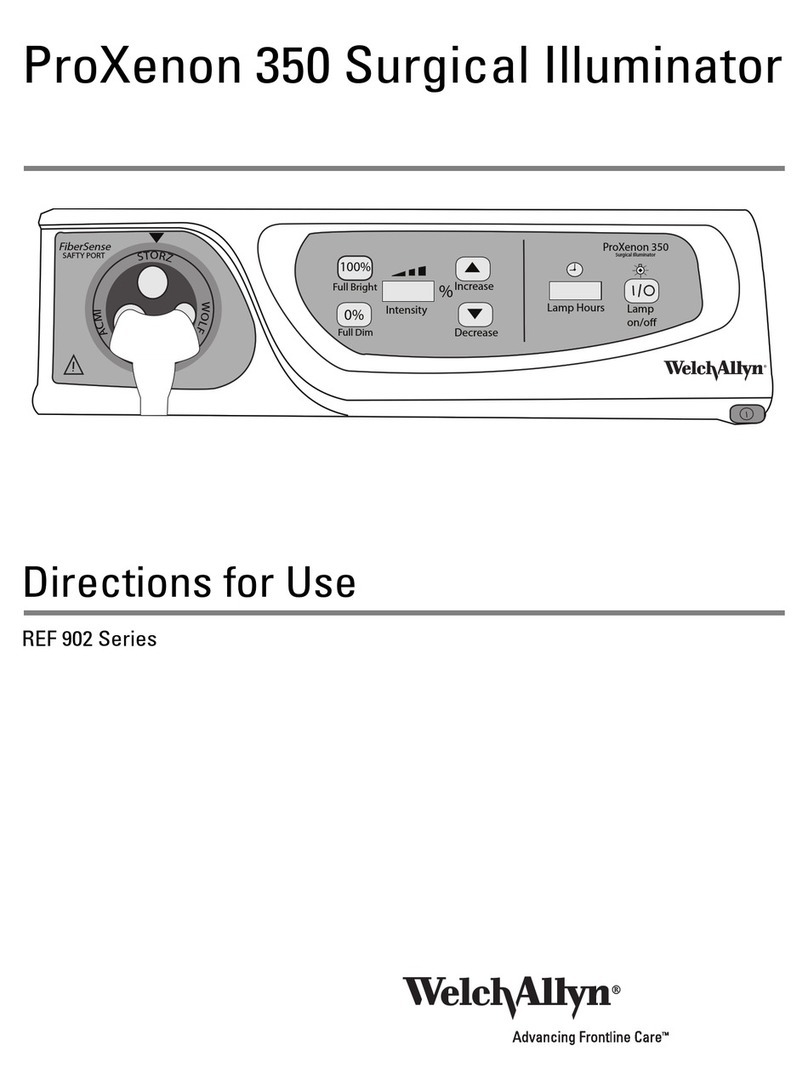

Welch Allyn ProXenon 350 User manual

Welch Allyn

Welch Allyn Halogen Exam Light II 48600 User manual

Welch Allyn

Welch Allyn XENON 300 User manual