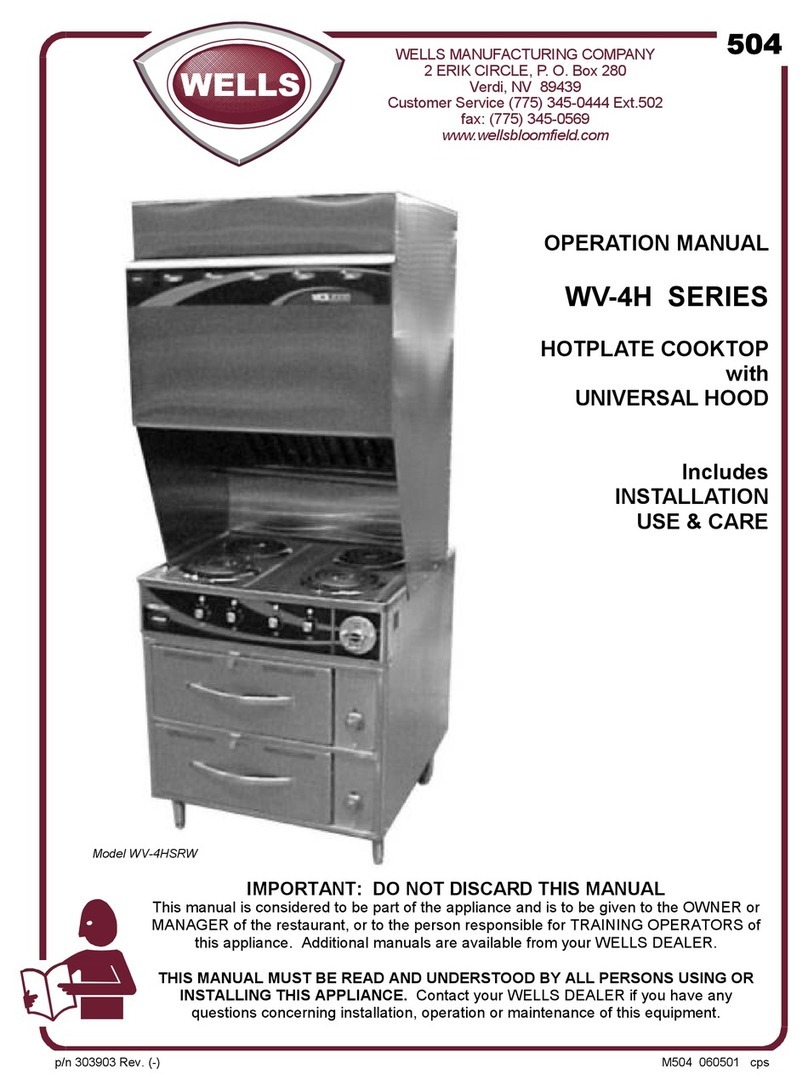

GENERAL

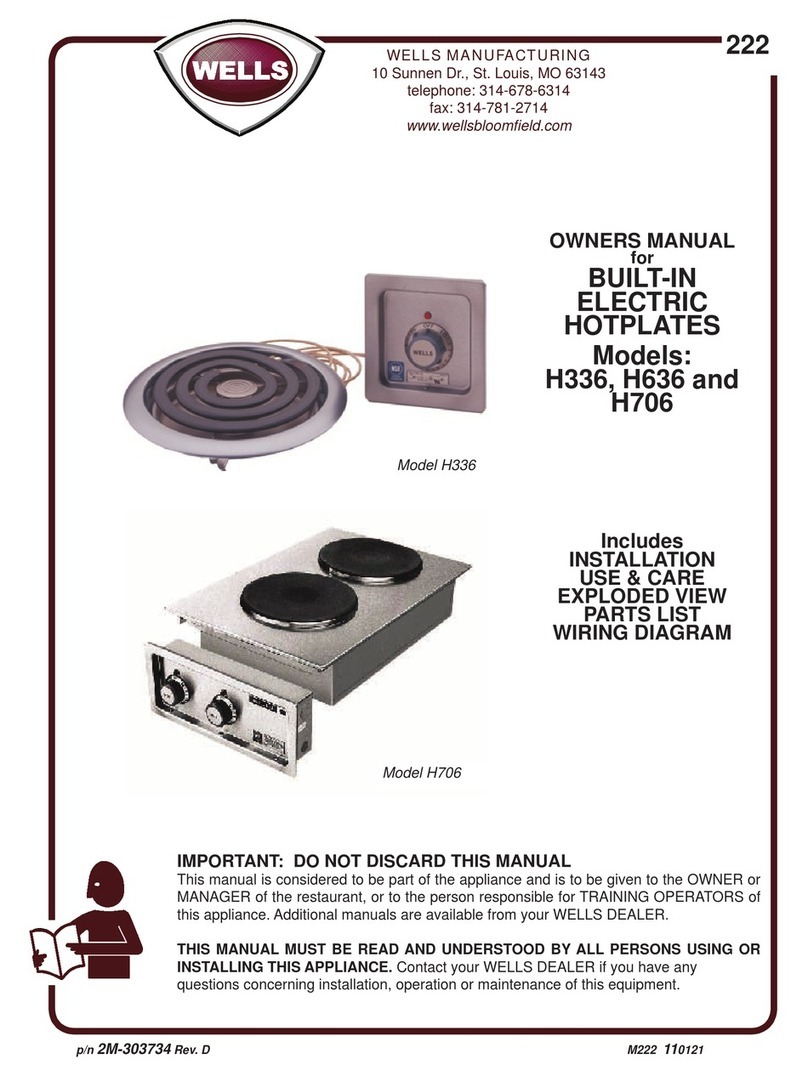

This appliance is intended for use in commercial establishments

only.

This appliance is intended

to prepare food for human consumption.

No other use is

recommended or authorized by the manufacturer or its

agents.

Operators of this appliance must be familiar with the appliance use,

limitations and associated restrictions. Operating instructions must be

read and understood by all persons using or installing this appliance.

Cleanliness of this appliance is essential to good sanitation. Read and

follow all included cleaning instructions and schedules to ensure the

safety of the food product.

Disconnect this appliance from electrical power before performing any

maintenance or servicing.

DO NOT splash or pour water on, in or over any controls, control

panel or wiring.

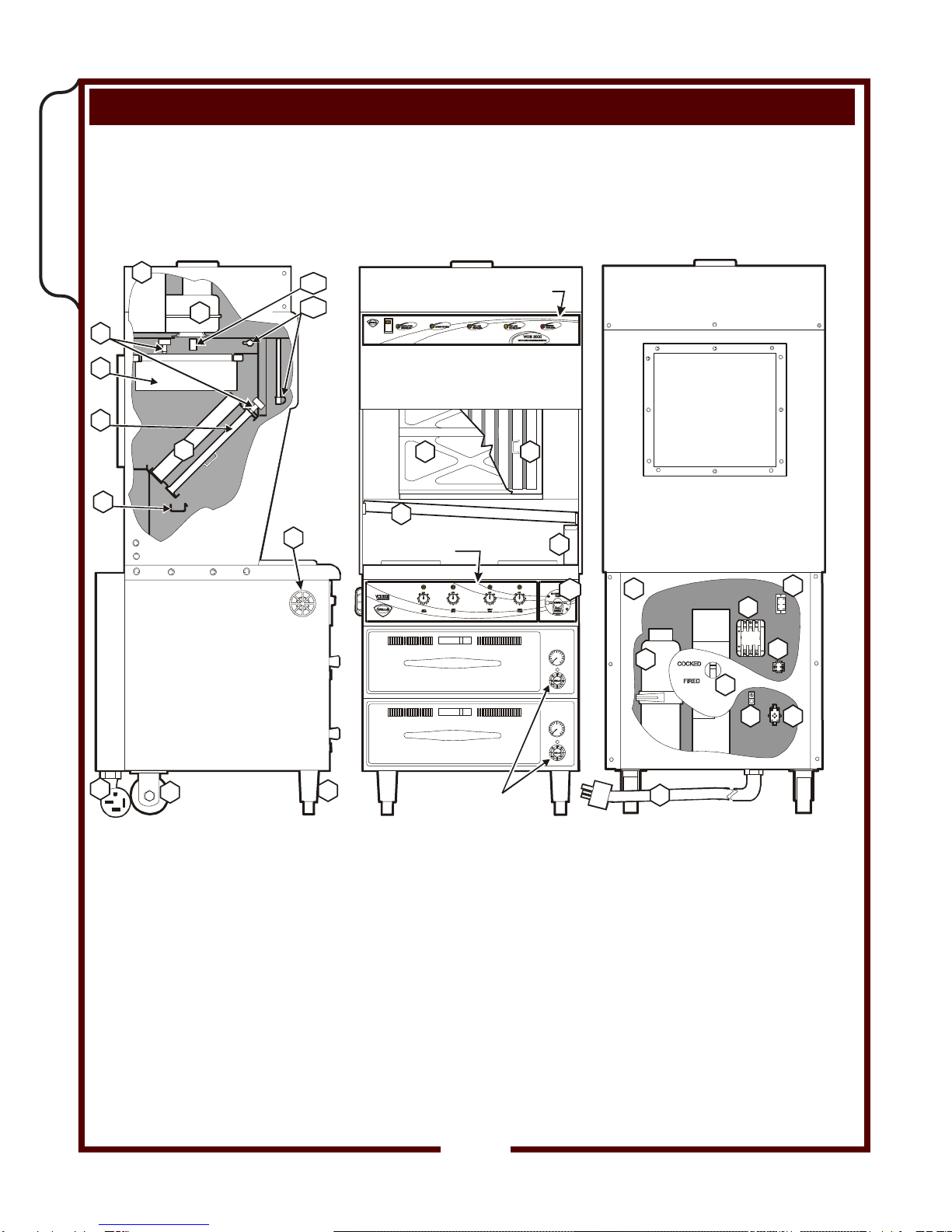

The technical content of this manual, including any wiring diagrams,

schematics, parts breakdown illustrations and/or adjustment

procedures, is intended for use by qualified technical personnel.

Any procedure which requires the use of tools must be performed by a

qualified technician. All service to the fire suppression system must be

performed by an authorized Ansul® agency.

This appliance is made in the USA. Unless otherwise noted, this

appliance has American sizes on all hardware.

IMPORTANT INSTALLATION NOTE:

6” clearance is required from back and sides of the appliance to any

combustible or non-combustible surface.

This installation requires a minimum ceiling height of 96" in order to

maintain adequate airflow.

WARNING:

RISK OF

INJURY

Installation procedures must

be performed by a qualified

technician with full knowledge

of all applicable electrical and

plumbing codes. Failure can

result in personal injury and

property damage.

WARNING:

ELECTRIC

SHOCK HAZARD

All servicing requiring access

to non-insulated electrical

components must be

performed by a qualified

technician.

Some procedures involve

exposed live circuits. Use all

due caution to avoid contact

with live electric circuits.

Failure to follow this warning

can result in severe electrical

shock.

CAUTION:

RISK OF

DAMAGE

DO NOT connect or energize

this appliance until all

installation instructions are

read and followed. Damage to

the appliance will result if

these instructions are not

followed.

PRECAUTIONS AND GENERAL INFORMATION

xi

SV504 SvcManual WV-4H(RW)