5

D. VOLTAGE CHECKS

NOTE: Resistance of the temperature probe is typically 5 megohm at room temperature, with

resistance decreasing as temperature rises. A shorted temperature probe will cause a runaway

condition, and an open probe will cause a continuousOFF condition.

1. Voltage between temperature controller terminals 2 & 3will be 120V any time the power switch

(item 66) is turnedON. Absence of 120V indicates power switchOFF or defective, or a wiring or

connector problem.

2. Voltage between TP1 and TP2 will be 120V when the unit is calling for heat. Absence of 120V,

when heating is required, indicates:

a.) Power switch defective orOFF; or,

b.) Temperature controller defective or open temperature probe; or,

c.) Wiring or connector problem

3. Voltage between TP1 and TP2 will be 120V when the unit is calling for heat. Failure to heat

when 120V is present indicates that the element being tested is defective.

4. Voltage between temperature controller terminals 1 & 3 will be 120V when the thermostat is

callingfor heat. Absenceof 120V, when heating is required, indicates:

a.) Power switch defective orOFF; or,

b.)Temperaturecontroller defective,or

c.) Shorted temperature probe or probe wiring shorted (check between terminals 4& 5); or,

d.) Wiring or connector problem

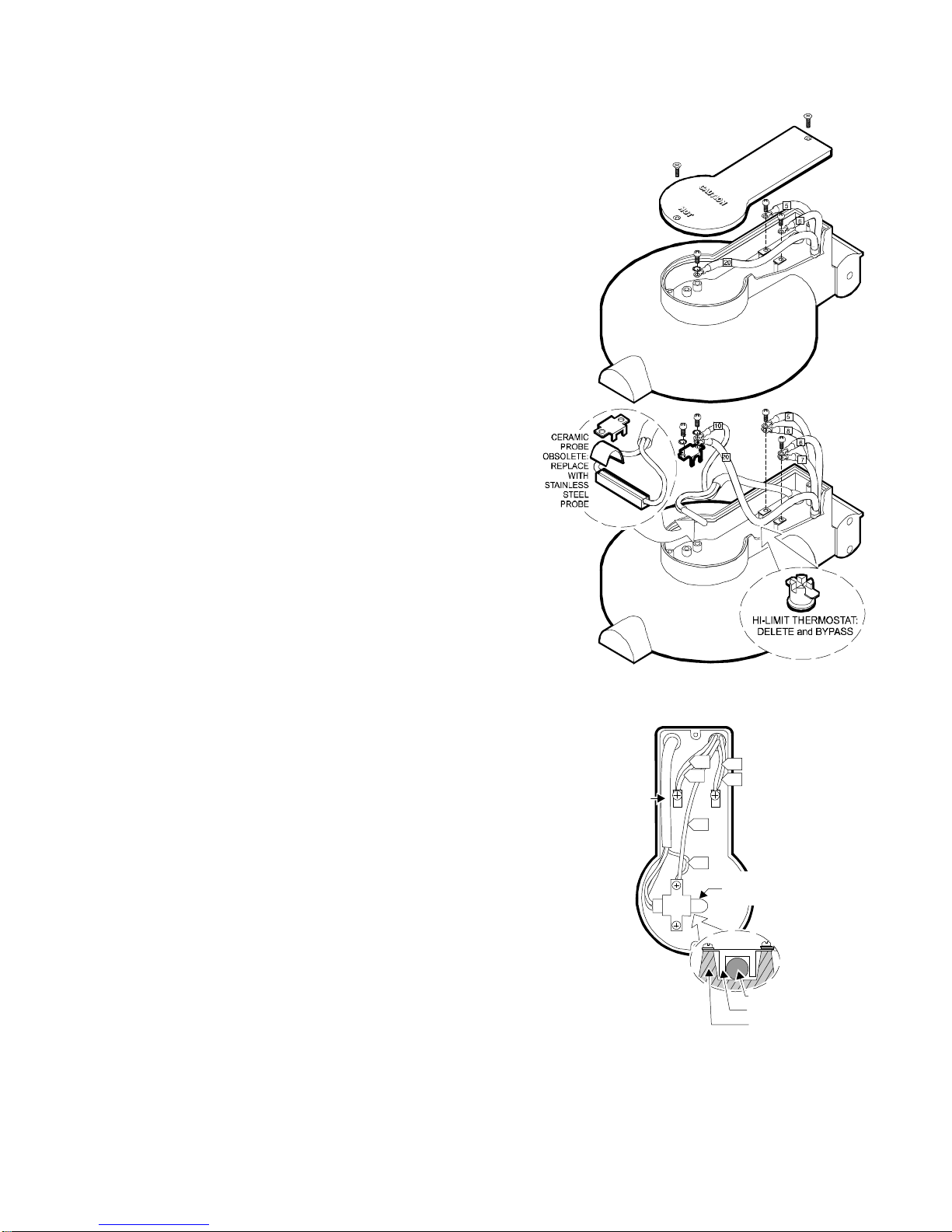

5. TP3 and TP4 are found only on waffle bakers equipped with a hi-limit thermostat. The hi-limit

thermostat should be removed and bypassed to increase the reliability of the waffle baker.

NOTE: Newer waffle bakers do not use a hi-limit thermostat. Existing hi-limit thermostats may

be safely removed and bypassed without affecting the UL approval. See page 11.

6. Voltage between timer terminals 2& 3is 120V any time the power switch is ON. Absence of 120V

indicates:

a.) power switch defective orOFF; or,

b.) a wiring or connector problem

7. Voltage between timer terminals 5& 6is 0V when the microswitch (item 10) is activated. Any

voltage other than 0V indicates a defective microswitch, or a wiring or connector problem.

8. Voltage between timer terminals 1& 2 is 120V during the cook cycle. Absence of 120V indicates

a defective timer module.

9. An indicator light NOT lit when reading a voltage betweentimer terminals 1& 2 is 120V indicates:

a.) loose or defective wiring to the indicator light; or,

b.) defective indicator light

10. Voltage between timer terminals 2& 4is momentarily 120V at the end of the cook cycle.

Absence of 120V indicates a defective timer module.