2809 II 2GD

TECH-552-ENrA

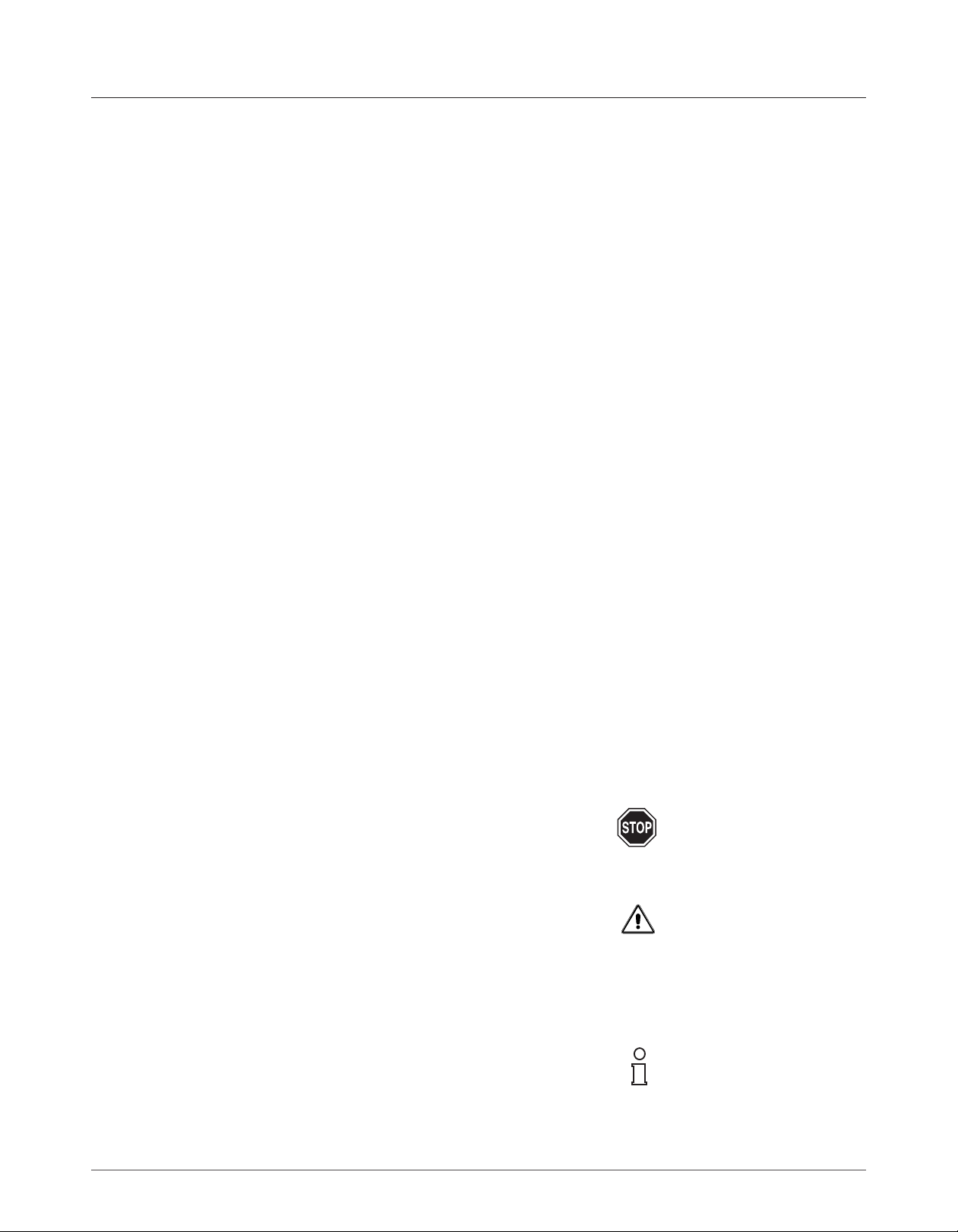

Installation and operating instructions for Westlock 2200 series valve position (AccuTrak) and control

(Quantum) monitors with mechanical switches, inductive proximity sensors or Magnum proximity switches

2200 SERIES ATEX AND IEC Ex CERTIFIED

INSTALLATION AND OPERATING INSTRUCTIONS

Copyright © Westlock Controls. All rights reserved

Note

Before installation of this product, please

ensure that the product and its certification

is suitable for the intended application. This

product uses various O-ring materials and an

Eastar copolyester visual indicator as standard.

If the equipment is likely to come into contact

with aggressive substances, then it is the

responsibility of the user to take suitable

precautions that prevent it from being

adversely affected, thus ensuring that the type

IEC Ex ETL 17.0008X

ITS 12 ATEX 17472X

Ex db IIB +H2 T* Gb Tamb -*°C to +*°C

Ex tb IIIC T*°C Db Tamb -*°C to +*°C IP6X

Flat cover -20°C to +85°C (T4); -20°C to +75°C (T5); -20°C to +60°C (T6)

Beacon cover -30°C to +85°C (T4); -30°C to +75°C (T5); -30°C to +60°C (T6)

Stainless steel -60°C to +85°C (T4); -60°C to +75°C (T5); -60°C to +60°C (T6)

When not fitted with a coil, the T4 upper ambient temperature may be +110°C

Environmental parameters: 11.6 psi (0.8 bar) to 15.9 psi (1.1 bar)

Air with normal oxygen content, typically 21%.

1 PRODUCT DESCRIPTION

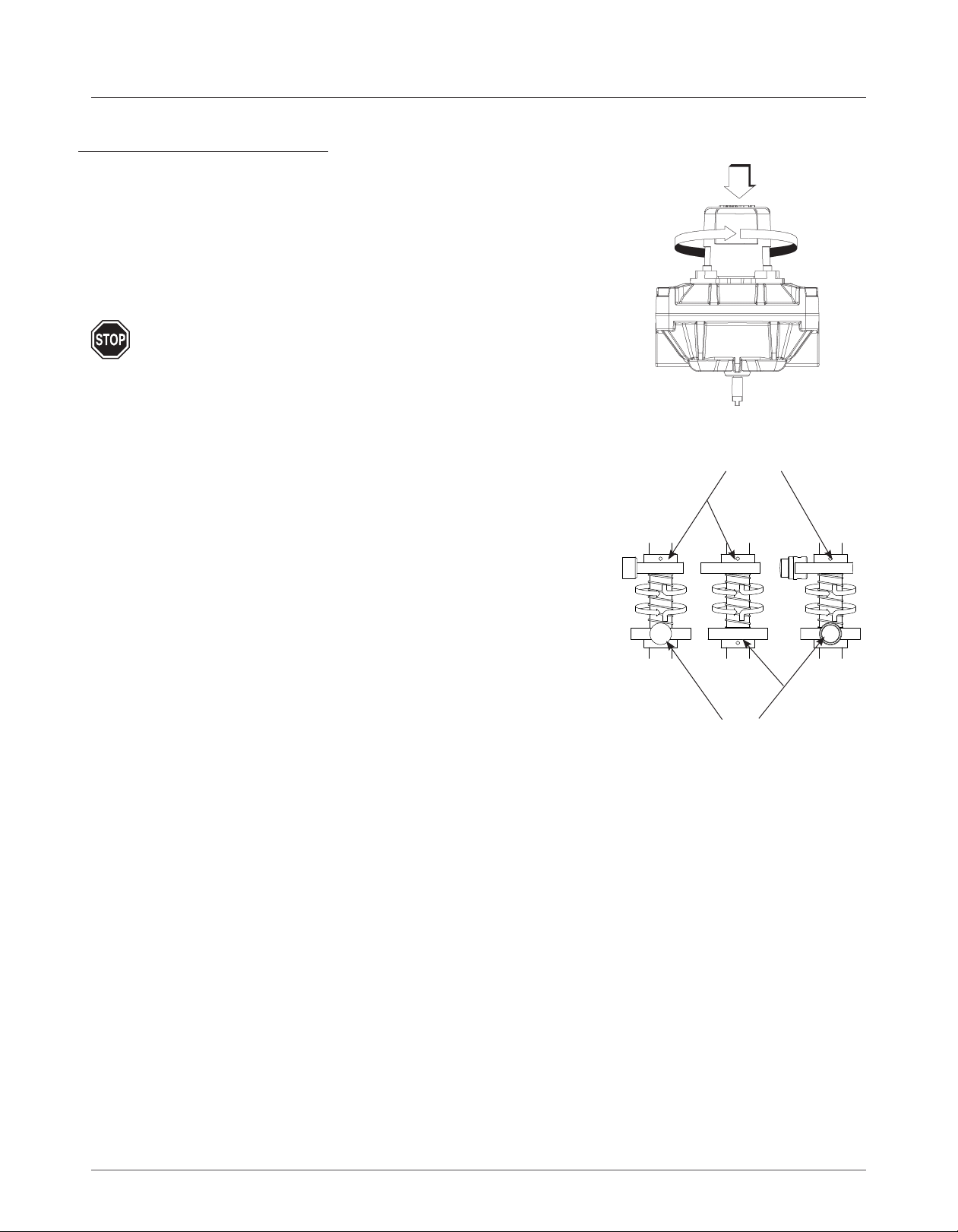

The 2200 series valve position/control

monitor provides two methods of end of

travel indication by the means of mechanical

switches, inductive proximity sensors or

proximity switches and an external visual

indicator.

For applications that require position feed

back, ancillary components such as a

4-20mA current signal transmitter or a

resistive signal feed back can be installed.

To allow this product to be used with network

communication bus protocols, the 2200 series

enclosure can house various network modules.

The 2200 series enclosure is available in both

aluminum or stainless steel and comprises two

parts, a cover and housing. The cover has three

variations, flat cover, standard beacon cover or

a high cover to suit different applications.

www.westlockcontrols.com

Warning

Electrostatic hazard, clean only with

damp cloth.

Page 1 of 8

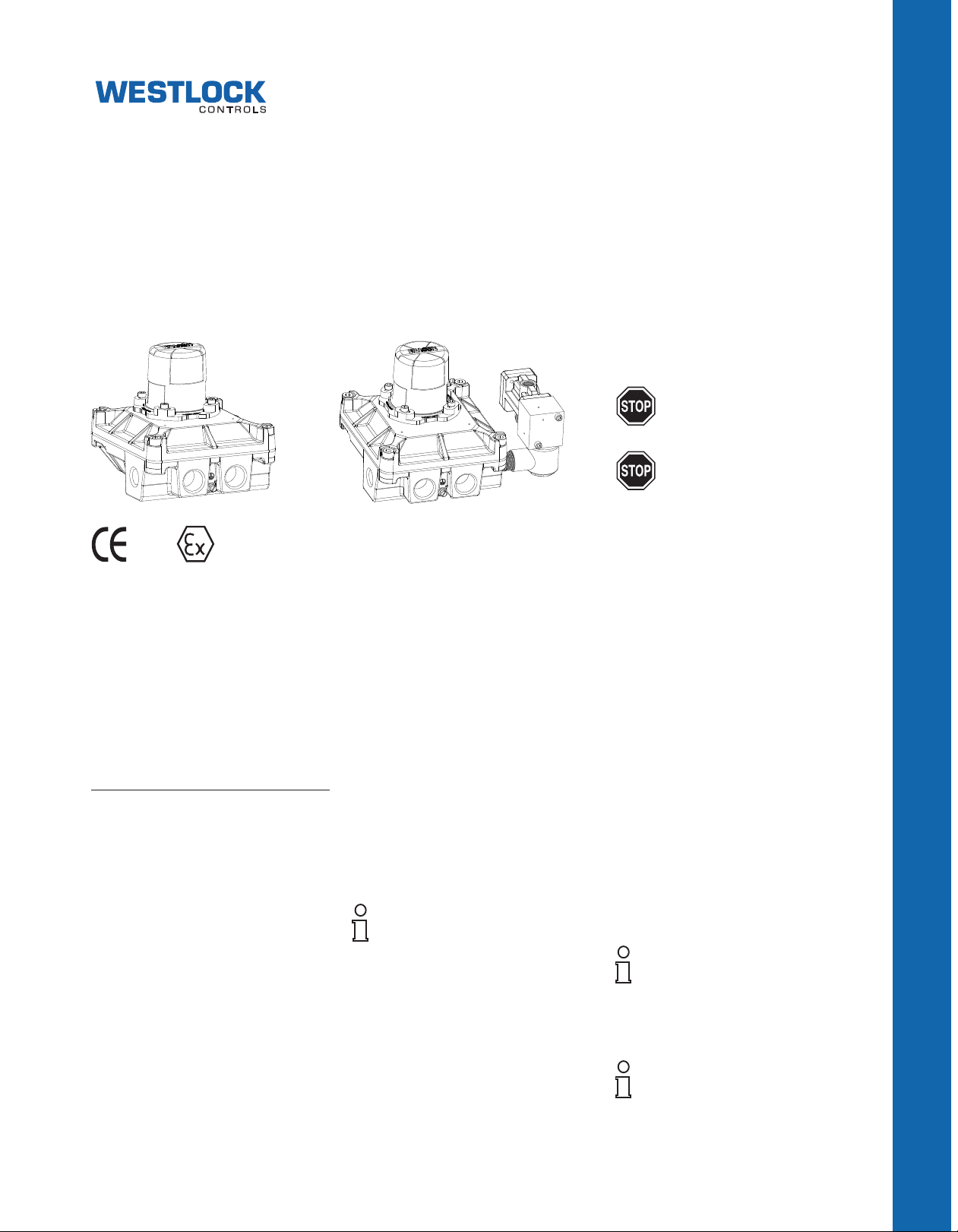

AccuTrak 2200 position monitor Quantum 2200 control monitor

The housing can offer a nipple mounted

solenoid coil and up to four (without coils)

of the following conduit entries; M20 x 1.5p,

1/2 - 14 NPT, or 3/4 - 14 NPT cable entries for

connection to an external power source via

appropriate ATEX and IEC Ex certified cable

glands.

of protection provided by the equipment is

not compromised.

Installation of any cable entry devices,

conduit entry devices or blanking devices

shall not compromise the degree of ingress

protection level IP6X for use in the presence

of combustible dusts.

The unit has an ingress protection of IP66/67

and therefore any conduit device fitted must

maintain this.

Note

These products have been certified with a

cable entry temperature rise of 4°C. Ensure

that this is taken into consideration when

selecting suitable cabling for the ambient

temperature in which the product is to be

used.

Note

These products are not intended to be

assembled directly to process pipe work etc.

that is heated or cooled to temperatures

outside of the range as indicated above.

Warning

Do not open when energized or when

an explosive atmosphere is present.