WIKA Operating Instructions RTDs and Thermocouples

11208287.03 06/2010 GB/D/F/E

9

GB

Potential measuring uncertainties due to aging eects

Thermocouples age and change their temperature/thermoelectric voltage curve. Type J thermo-

couples age slightly due to oxidation of the pure metal leg. As for Type K and to a lesser extend

Type N (NiCrSi-NiSi) thermocouples, considerable changes in thermo-electric voltage can occur

at high temperatures due to chromium depletion in the NiCr leg, which results in a decreasing

thermo-electric voltage.

This eect is accelerated if there is a shortage of oxygen, since a complete oxide skin is unable to

form on the surface of the thermocouple and protect it from further oxidation. The chromium in the

alloy oxidizes, but not the nickel, giving rise to the "green rot" that eventually destroys the thermo-

couple. During the fast cooling of NiCr-Ni thermocouples, that has been operating at temperatures

above 700 °C, certain states occur within the crystal structure (short-range order), which in Type

K elements can result in a change in thermoelectric voltage of up to 0.8 mV (K eect).

It has been possible to reduce the short-range order eect in Type N (NiCrSi-NiSi) thermocoup-

les by alloying both legs with silicon.

The eect is reversible and can be cancelled by annealing above 700 °C with subsequent slow

cooling. Thermocouples with smaler diameters react sensitively in this respect. Even cooling in

still air can cause deviations greater than 1 K.

The application range of these thermometers is limited by the permissible max. temperature of the

thermocouple as well as the max. temperature of the thermowell material.

Listed thermocouples are available both as single or duplex thermocouples. The thermocouple

will be delivered with an insulated measuring point, unless explicitly specied otherwise.

Sensor tolerance value

A cold junction temperature of 0 °C is taken as basis with the denition of the sensor limiting

error of thermocouples. When using a compensating cable or thermocouple cable, an additional

measuring error must be considered.

For tolerance values and further specications see current WIKA Data Sheet or order documentation.

4. Design and function

4.1 Short description

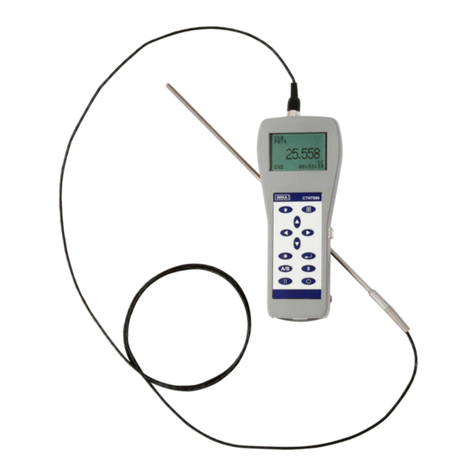

These thermometers (resistance thermometers and thermocouples) detect temperatures in

processes.

These thermometers are suitable, depending on the version, for low, medium and high process

requirements.

They can be assembled as cable probes or as thermometers with a connection head. Optionally,

a temperature transmitter can be built into the connection head. For this temperature transmitter,

separate operating instructions will be enclosed.

Certain thermometer versions can be combined with a large number of thermowell designs.

Operation of these thermometers without a thermowell is only appropriate in special cases.

3. Specications / 4. Design and function