EN

14073045.06 10/2020 EN/DE/FR/ES

WIKA operating instructions model TR25 (Ex i)8

■

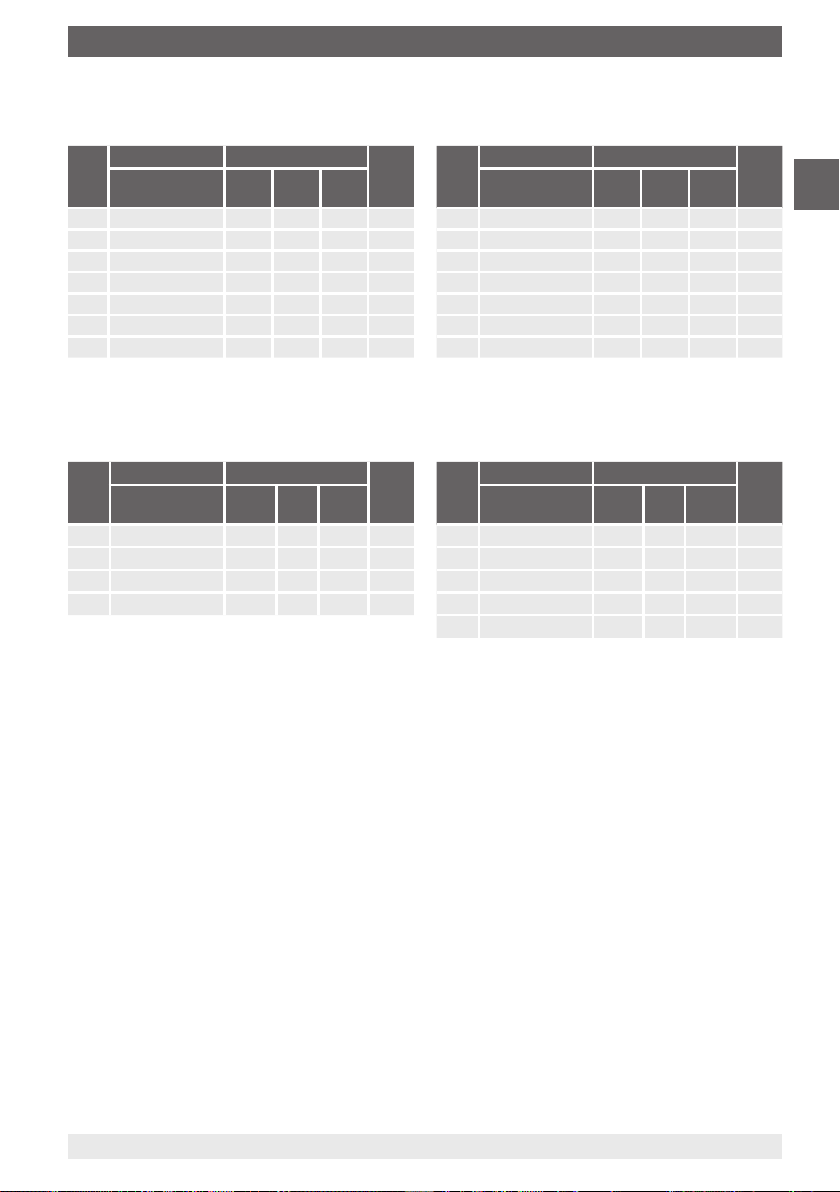

Version with threaded connection

Thread per DIN 11851

14073164.01

Pipe inner

Ø Di

Thread Ø G

Insertion length L

Overall length LG

Thread per DIN 11864-1 form A for pipes

DIN 11866 row A

14073164.01

Pipe inner

Ø Di

Thread Ø G

Insertion length L

Overall length LG

Thread NEUMO BioConnect®

Thread Ø G

Insertion length L

14073164.01

Pipe inner Ø Di

Thread NEUMO BioConnect®

for pipes per DIN 11866 row A

NEUMO BioConnect®thread for pipes per

DIN 11866 row B (ISO 1127)

Flange connections, clamp connections and further

nominal widths on request.

2) Maximum operating temperature 150 °C

3) All thermowells of this series that are internally

pressurised, with a nominal diameter (DN) greater than

25 mm, are manufactured and tested to module H of the

pressure equipment directive.

DN For pipe Dimensions PN

2) 3)

Outer Ø x wall

thickness

Ø DiG L

15 19 x 1.5 16 M30 x 1.5 84 40

20 23 x 1.5 20 M36 x 2 84 40

25 29 x 1.5 26 M42 x 2 84 40

32 35 x 1.5 32 M52 x 2 84 40

40 41 x 1.5 38 M56 x 2 84 40

50 53 x 1.5 50 M86 x 2 84 25

65 70 x 2 66 M90 x 3 88 25

DN For pipe Dimensions PN

2) 3)

Outer Ø x wall

thickness

Ø DiG L

15 21.3 x 1.6 18.1 M30 x 1.5 84 40

20 26.9 x 1.6 23.7 M36 x 2 84 40

25 33.7 x 2 29.7 M42 x 2 84 40

32 42.4 x 2 38.4 M52 x 2 84 40

40 48.3 x 2 44.3 M56 x 2 84 25

50 60.3 x 2 56.3 M86 x 2 84 25

65 76.1 x 2.3 71.5 M90 x 3 88 16

DN For pipe Dimensions PN

2)

3)

Outer Ø x wall

thickness

Ø DiGLG L

10 13 x 1.5 10 Rd 28 x 1/8 84 76 40

15 19 x 1.5 16 Rd 34 x 1/6 84 76 40

20 23 x 1.5 20 Rd 44 x 1/6 84 72 40

25 29 x 1.5 26 Rd 52 x 1/6 84 70 40

32 35 x 1.5 32 Rd 58 x 1/6 84 70 40

40 41 x 1.5 38 Rd 65 x 1/6 84 70 40

50 53 x 1.5 50 Rd 78 x 1/6 84 70 25

65 70 x 2 66 Rd 95 x 1/6 88 72 25

DN For pipe Dimensions PN

2)

3)

Outer Ø x wall

thickness

Ø DiGLG L

10 13 x 1.5 10 Rd 28 x 1/8 84 76 40

15 19 x 1.5 16 Rd 34 x 1/8 84 76 40

20 23 x 1.5 20 Rd 44 x 1/6 84 74 40

25 29 x 1.5 26 Rd 52 x 1/6 84 72 40

32 35 x 1.5 32 Rd 58 x 1/6 84 70 40

40 41 x 1.5 38 Rd 65 x 1/6 84 70 40

50 53 x 1.5 50 Rd 78 x 1/6 84 70 25

65 70 x 2 66 Rd 95 x 1/6 88 72 25

2. Design and function