GB

14004105.01 05/2011 GB/D/F/E

4 WIKA operating instructions model 54, Twin-Temp

1. General information

■

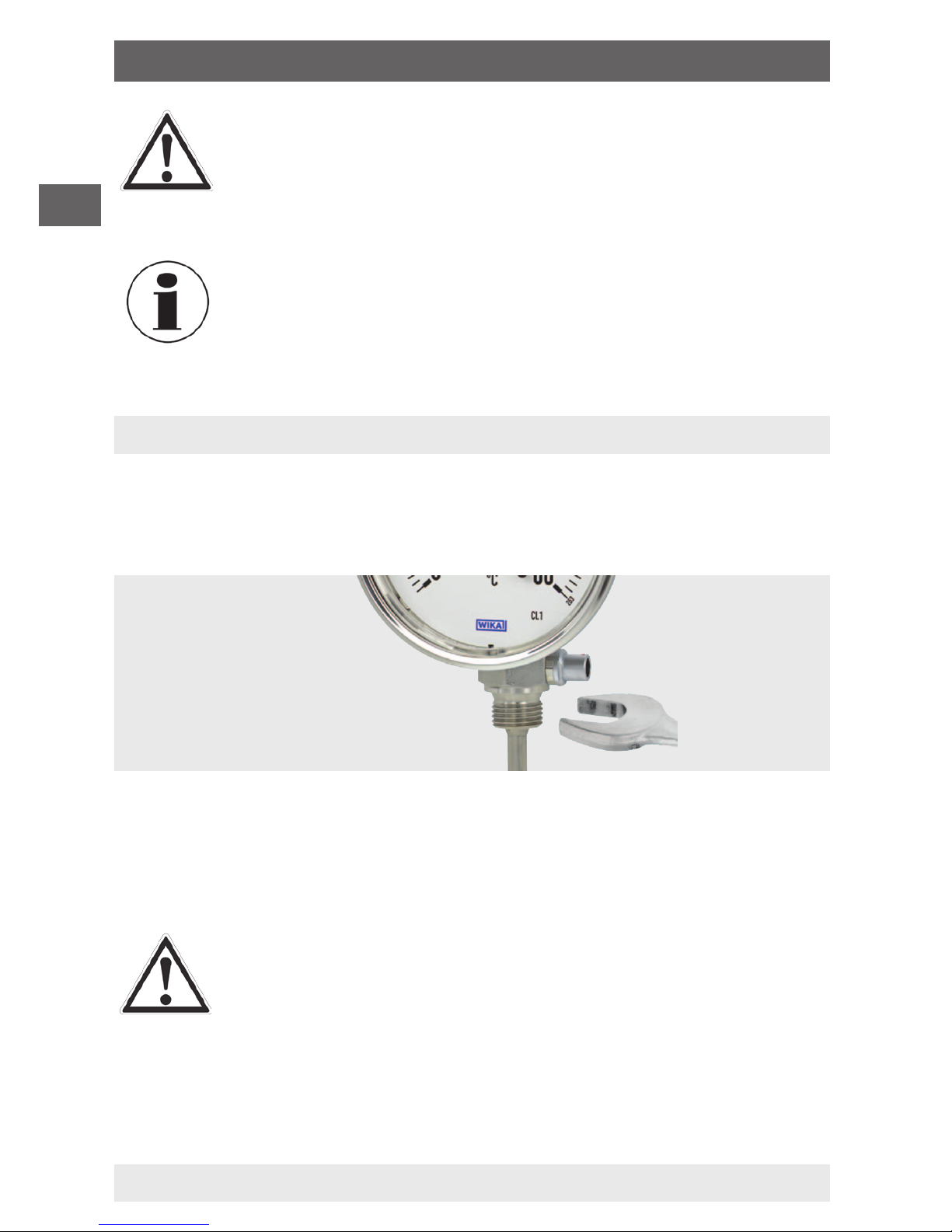

The combined bimetal thermometer described in these operating

instructions has been designed and manufactured using state-of-

the-art technology. All components are subject to stringent quality

and environmental criteria during production. Our management

systems are certied to ISO 9001 and ISO 14001.

■

These operating instructions contain important information on

handling the combined bimetal thermometer. Working safely requires

that all safety instructions and work instructions are observed.

■

Observe the local accident prevention regulations and

general safety regulations, in eect for the combined bimetal

thermometer‘s range of use.

■

The operating instructions are part of the product and must be kept

in the immediate vicinity of the combined bimetal thermometer and

readily accessible to skilled personnel at any time.

■

Skilled personnel must have carefully read and understood the

operating instructions prior to beginning any work.

■

The manufacturer‘s liability is void in the case of any damage

caused by using the product contrary to its intended use,

non-compliance with these operating instructions, assignment

of insuciently qualied skilled personnel or unauthorised

modications to the combined bimetal thermometer.

■

The general terms and conditions contained in the sales

documentation shall apply.

■

Subject to technical modications.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: TV 15.01

1. General information