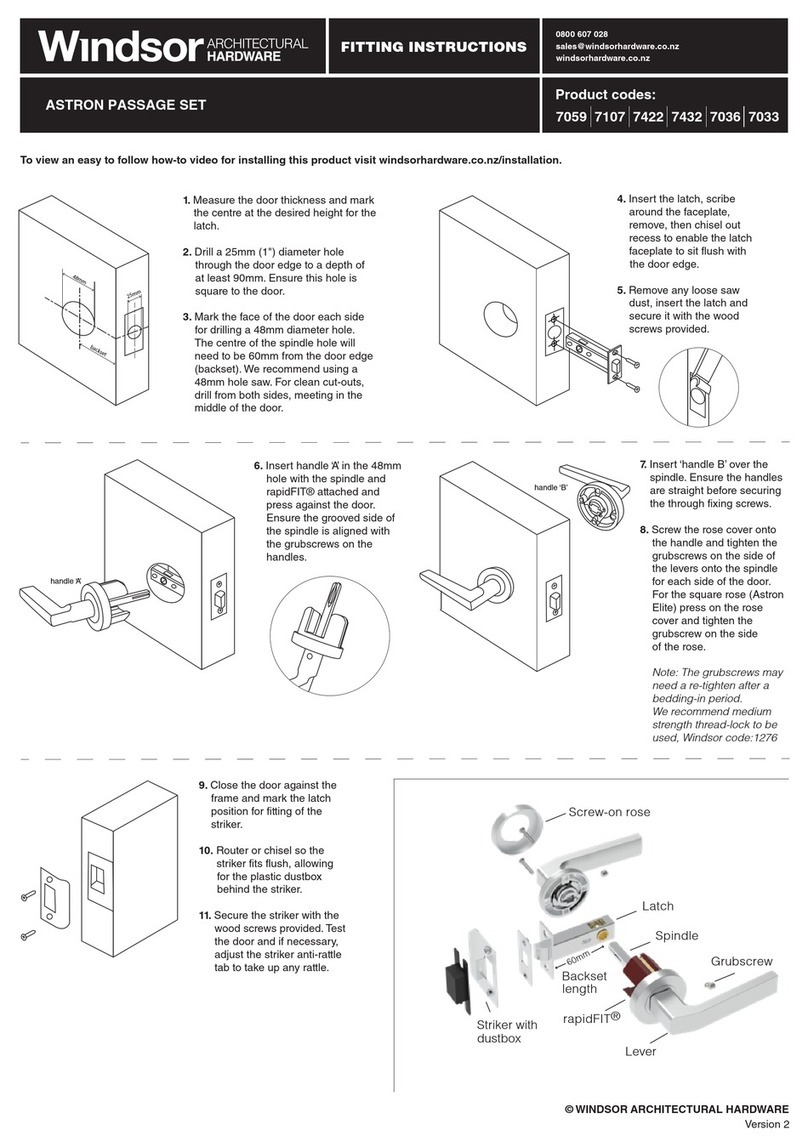

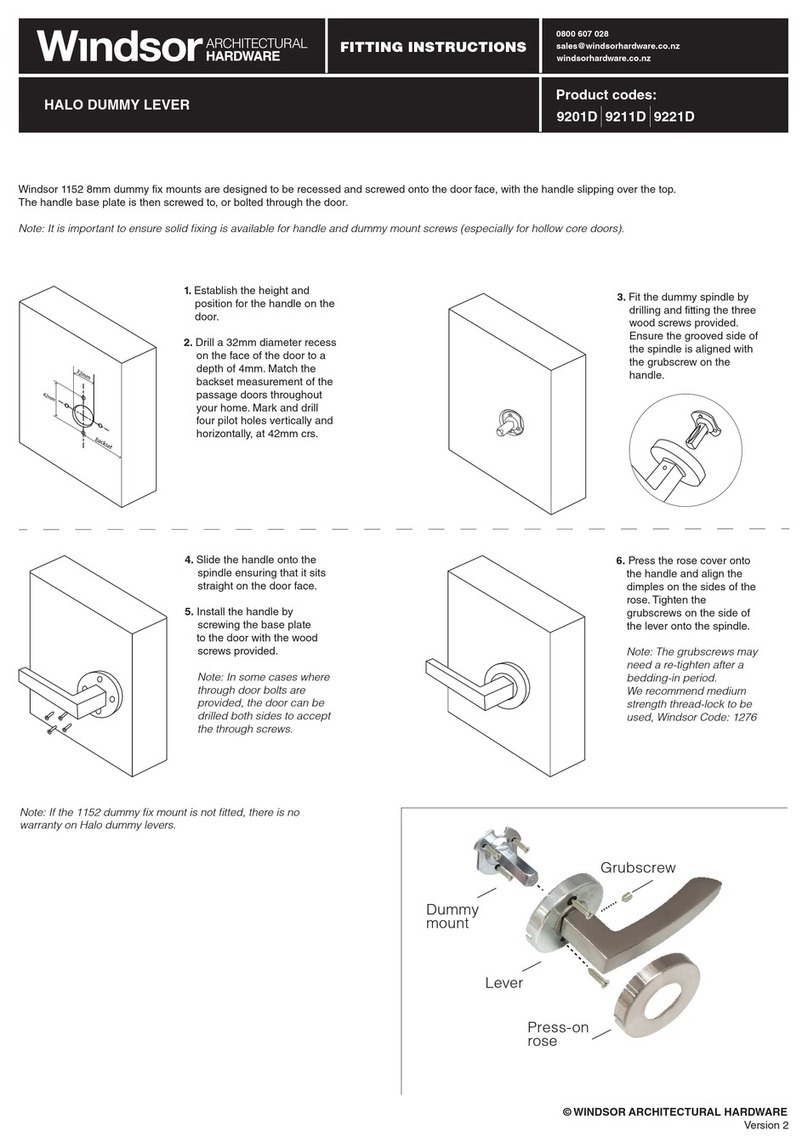

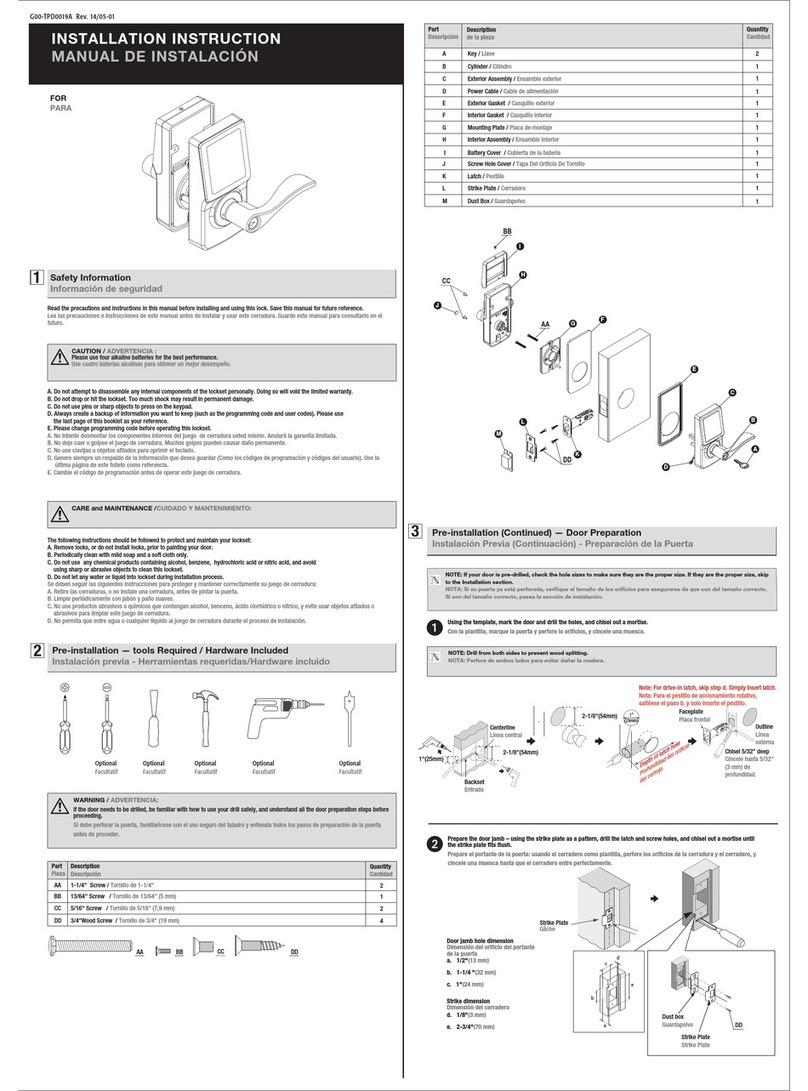

5. Insert the sliding threaded

sleeve into the top shaft,

choosing the correct height

depending on the location of

the mortice hole drilling. The

sliding threaded sleeve can be

adjusted between 55mm to

100mm to the centre of the

square shaft.

6. Fit the rubber weather seals to the

front and back panels.

7. Connect the wire through the door into

the back panel.

0800 607 028

sales@windsorhardware.co.nz

windsorhardware.co.nz

FITTING INSTRUCTIONS

SMART ENTRY LEVER SET

© WINDSOR ARCHITECTURAL HARDWARE

2. Install the mortice lock using the

cropping template provided.

Version 2

Product codes:

Package Contents

Part Description QTY Part Description QTY

A Front Panel 1

B Back Panel 1

C Mortice Lock 1

D Cards 3

E Mechanical Keys 2

F Waterproof Rubber Plates 2

G U-Clip 1

H Striker & Dustbox 1

I Sliding Threaded Sleeves 35x8mm 2

J Sliding Screws 16x5mm 2

K Mortice Screws 10x5mm (for aluminium doors) 4

L Mortice Screws 25x4mm (for wooden doors) 4

M M5x30mm Screws (for door thickness 30-65mm) 1

N M5x50mm Screws (for door thickness 50-65mm) 1

O M5x70mm Screws (for door thickness 50-65mm) 1

P Spindle for door thickness 35-55mm 1

Q Spindle for door thickness 45-65mm 1

R Chuck 1

S Loctite - Threadlock (Windsor code 1276) 1

3. Install the spindle into the back of the

lever of the front panel. Insert the split

pin and bend its front end to fix it into

the square shaft (b). Turn the spindle

and square shaft to ensure the small

arrow is pointing towards the hinges (a).

4. Fit the threaded sleeve to the bottom

spigot by turning it counterclockwise

and tighten it.

8. Hold the front panel

against the door face,

sliding the spindle and

threaded sleeves

through the drilled

holes. Install the back

panel by tightening the

screws through the back

panel into the threaded

sleeves. Ensure the

panels are sitting

straight on the door.

9. Insert 4 Alkaline

(AA)1.5V batteries*,

slide the battery cover

onto the interior unit

and tighten it with the

screw provided.

* Warranty void if Alkaline

batteries are not used

a

b

1501 1513

1. Ensure the lever is handed to suit your door. To

adjust the handing, remove the Phillips screw in the

back of the handle by turning it counterclockwise.

Remove the lever and turn it around. Then insert

the screw back into the handle seat and re-tighten

by turning it clockwise*. Both front and back panels

will require this adjustment.

* Recommend using Loctite (Windsor code 1276) on

handle screws.

This product is covered by a one year electronic

warranty and 10 year mechanical warranty.

Measurements

Mortice Locks

Lever Styles

Code Backset* Case

Height*

Case

Depth*

1520 30 174 45

1521 35 174 50

1522 45 174 60

1523 60 174 85

1525 35 218 48

Code Body

Height*

Body

Width*

Lever Protrusion*

1501 310 40 130 78

1511 310 40 73 78

1512 310 40 73 78

1513 310 40 130 78

*measurements in mm

10. To initialise the system

open the cover plate of

the back panel, press

the ‘Reset’ button

pictured for 5 seconds,

then lift the lever to throw

the bolt to complete the

initialisation process.

Use this step only

when resetting the lock

to factory settings. Not

required on first setup.