6 Translation of the original operation manual Airless

Phoenix_BAoDB_en_1210 •jw

Emissions

It is possible for solvent vapours to occur, depending on

the materials used.

Therefore, please ensure the workplace is sufciently

ventilated in order to avoid damage to health and property.

Always observe the processing information given by the

material manufacturer.

The sound pressure level of the equipment is below 85 db

(A). The operator is responsible for compliance with the

rules covering the prevention of accidents due to „noise“

(BGV B3).

Therefore, pay special attention to the environmental

conditions at the site, e. g. noise can be increased if the

machine is installed in or on hollow bodies.

Exact specications covering noise emissions are found in

Chapter 11.1 Technical specications.

2.6 Sources of danger

Always remember, plural component systems operate at

very high pressure levels and unauthorized usage could

lead to life-threatening injuries.

Warning!

Material exits the spray gun at very high pressure levels.

The spray jet can cut or be injected under the skin or eyes,

resulting in serious injuries.

➤Never point the spray gun towards yourself, other

people or other living creatures.

➤Never hold your nger or hand in front of the spray gun

and never reach into the spray jet.

Warnung!

Unintentional triggering of the spray gun can lead to injury

or damage to property.

➤Always apply the spray gun safety catch, regardless

how short the pause in spraying is.

➤Before operation, always check the function of the

spray gun safety catch.

Warnung!

Components that do not correspond to the maximum pres-

sure created by the pump are quickly prone to rupture,

leading to serious injuries.

➤Fluid hoses must be rated to correspond to the maxi-

mum operating pressure of the unit, with an appropri-

ate safety factor allowance.

➤No hoses may show signs of leaks, kinks, wear or

blisters.

➤All hose connections must be tight.

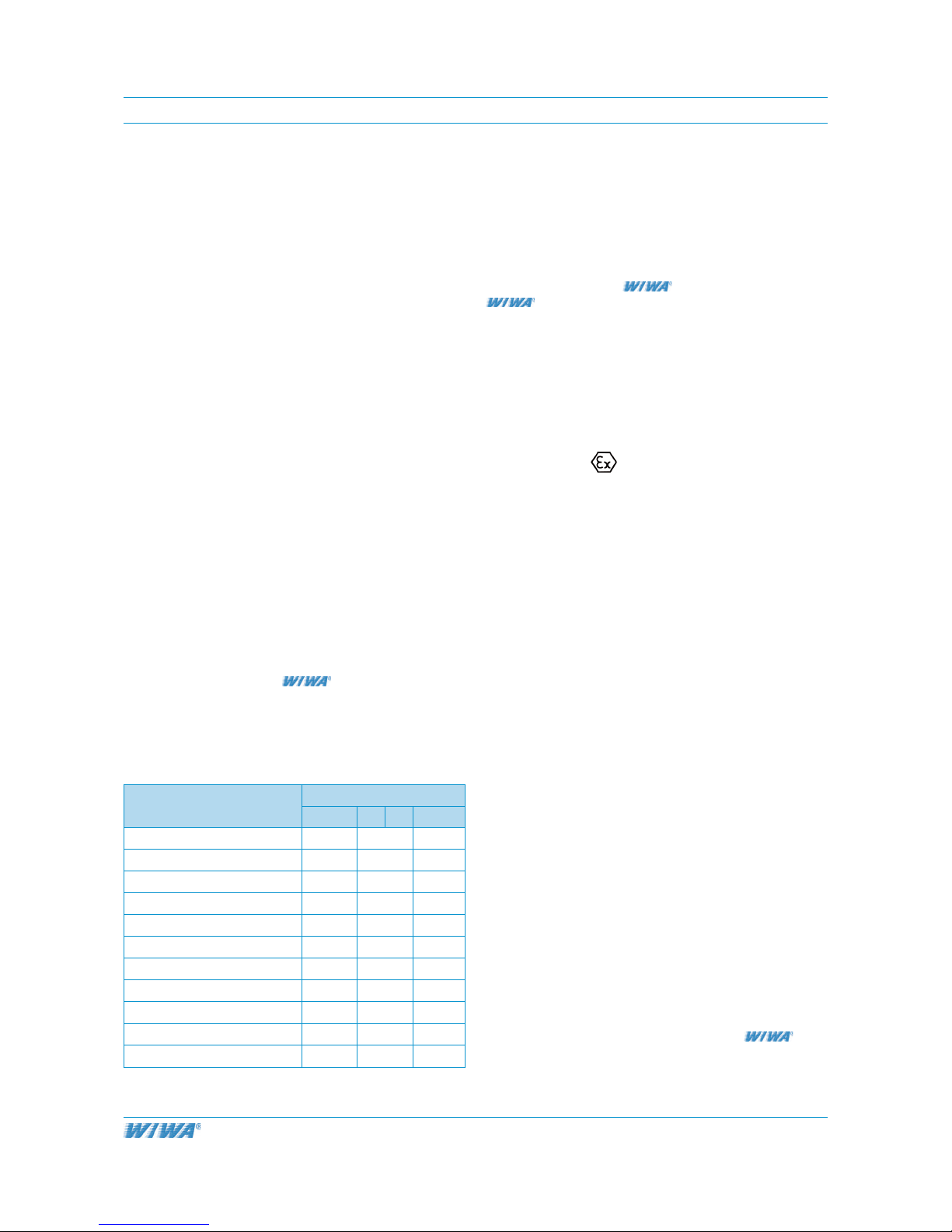

It must be ensured that

the pump is grounded

separately or together

with the equipment it is

mounted to (maximum

resistance 106 Ω, picture

2.4.1 ground / potential

equalization).

Equipment that is not rated as explosion-proof may not

be operated in areas requiring explosio-proof protection.

Pneumatically driven Airless spraying equipment is not

effected by this. If, however, agitators, heaters or other

electrical accessories are used, they must rst be checked

for their explosion-proof rating. Plugs for heaters, agita-

tors, etc. may only be connected to sockets outside of

the explosion-proof area, even if the unit itself is rated as

explosion-proof.

Other usage is not in line with regulations.

Before equipment is used for other purposes

or with other materials, and, therefore, not according to

the regulations, permission should be obtained from the

manufacturer as the guarantee is otherwise invalid. The

observation of technical documentation and the compli-

ance with specied operational, maintenance and starting

guidelines are manditory in accordance with the valid

regulations.

2.5 Pump surroundings

Rebuilds and modications

For safety reasons, it is not allowed to carry out rebuilds or

changes without authorization.

Protective equipment may not be dismounted, changed or

neglected.

If using components which are not produced or delivered

by , warranty coverage is negated as well as

liability. The machine may only be operated within the

prescribed limits and machine parameters.

Danger caused by accessories and spare parts

If you use original attachments and original spare parts

from

,

the compatability with our equipment is

guaranteed. It is, however, essential that the safety regu-

lations of the attachments and spare parts are observed.

You can nd these safety regulations in the User’s Hand-

book located with the spare parts lists.

If you use attachments and spare parts from another

source, cannot guarantee the safety of the entire

system. In this case, our guarantee does not cover any

damage or injury caused by such attachments and spare

parts.

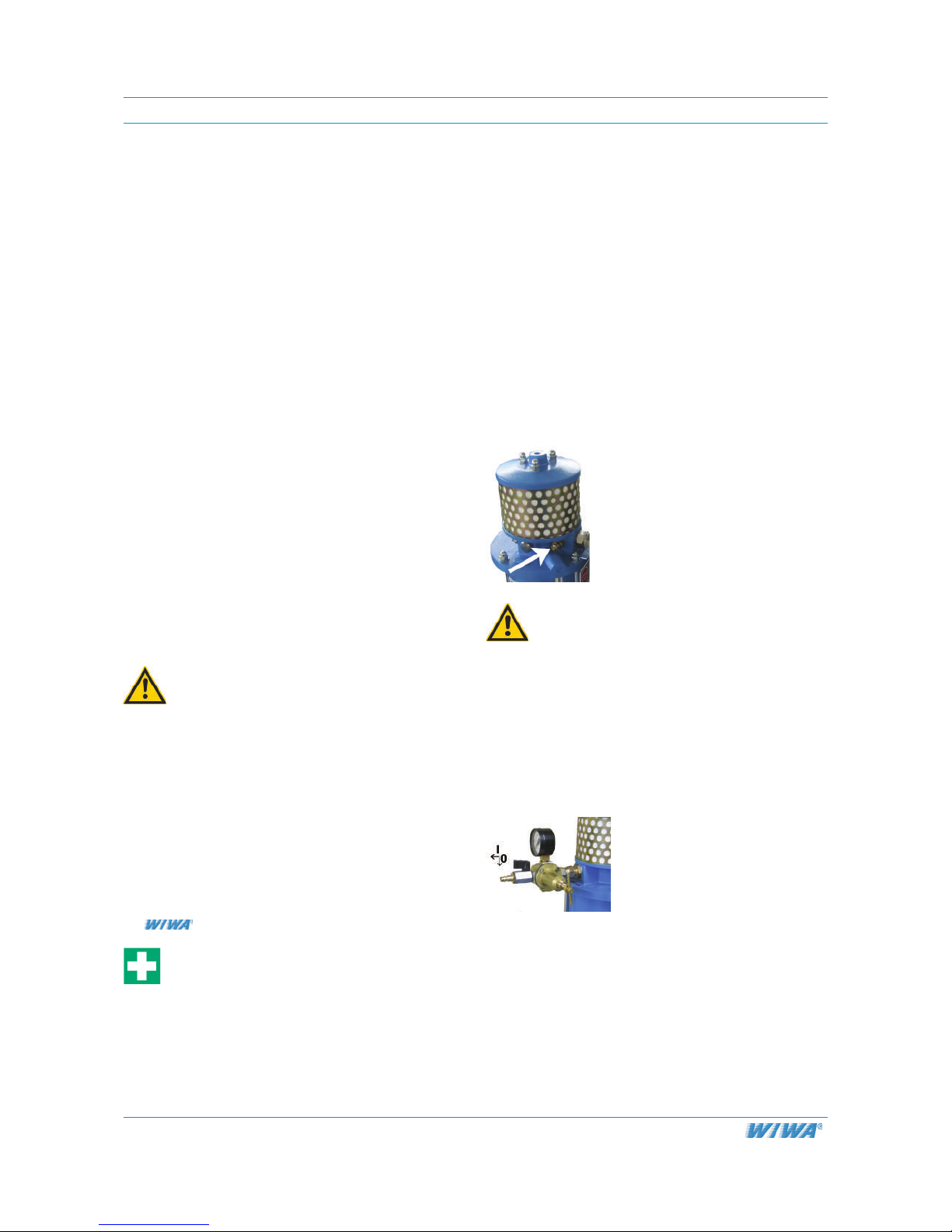

Picture 2.4.1 Groun-

ding screw on the

high-pressure lter

2 Safety