12 Translation of the original operating instructions DUOMIX 270

DM270_BAoDB_en_1507 • rs

Safety

In systems that are closed or under pressure, dangerous chemical reactions

may arise, if parts produced from aluminium or galvanised parts come into

contact with 1.1.1 - trichloroethane, methylene chloride or other solvents that

contain halogenated chlorinated hydrocarbons (CFCs). If you wish to process

materials that contain the aforementioned substances, we recommend that you

contact the material manufacturer in order to clarify their suitability for use.

A range of machines in rust and acid-resistant designs is available for these

types of materials.

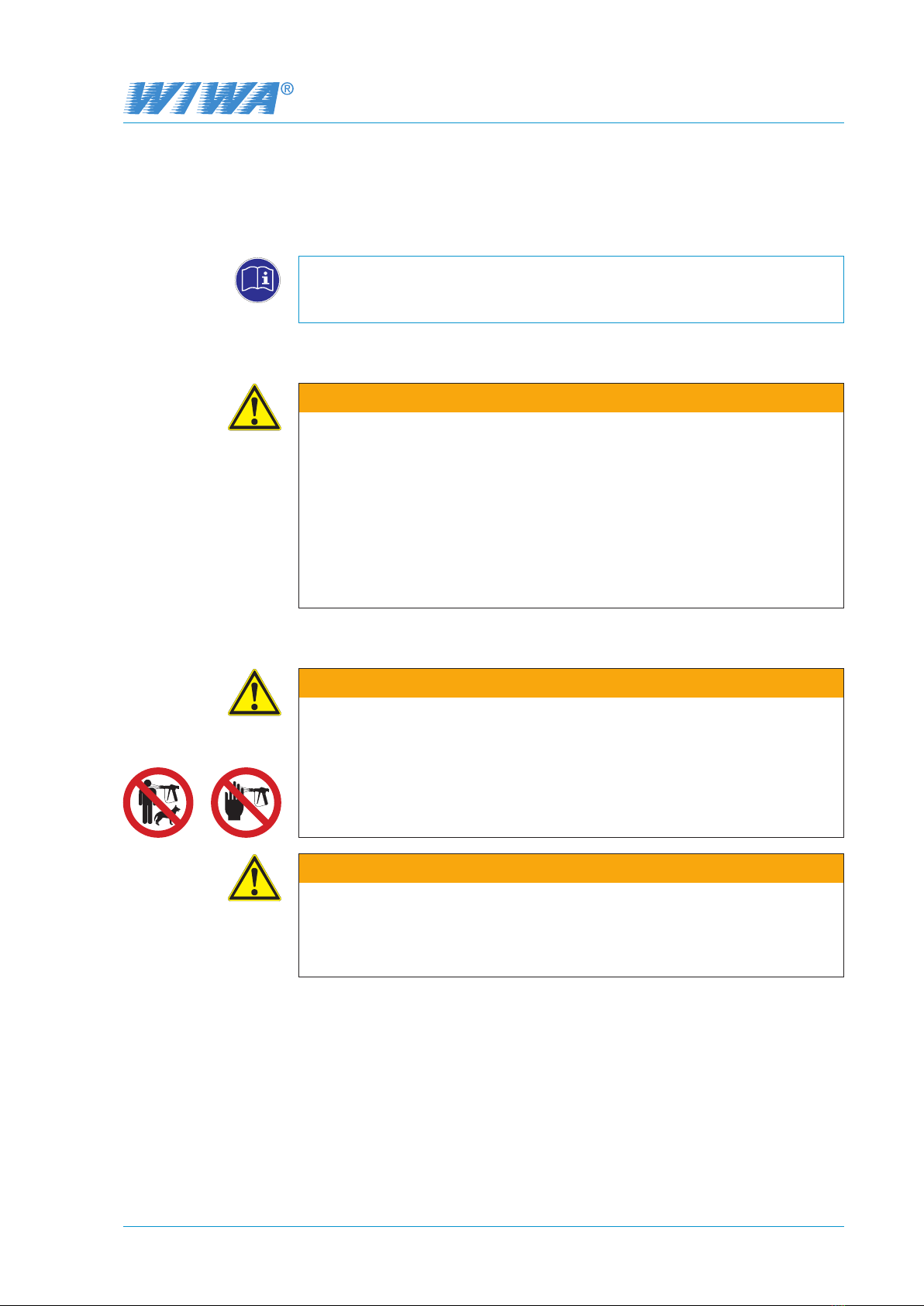

2.3 Information signs on the machine

The information signs displayed on the

machine, like the safety card (see Fig. 1),

indicate possible hazard points and must

be observed.

They must not be removed from the ma-

chine.

Damaged and illegible information signs

must be replaced immediately.

Also read and observe the safety informa-

tion in the operating instructions!

Für Ihre Sicherheit

For your safety •Pour votre sécurité

Por razones de seguridad •Для вашей безопасности

Güvenliğiniz için • Dla Twojego bezpieczeństwa

För din säkerhet • Para a sua segurança

© 05 / 2015 • 0642169

www.wiwa.de

www.wiwa.com

Spritzpistole nicht auf Personen oder Tiere richten

Do not point spray gun at persons or animals

Ne jamais diriger le pistolet de pulvérisation en direction de personnes ou d‘animaux

No dirigir la pistola pulverizadora hacia personas ni animales

Не направляйте пистолет-распылитель на людей или животных

Püskürtme tabancasını kişilere veya hayvanlara doğrultmayın

Pistoletu natryskowego nie kierować w stronę ludzi lub zwierząt

Rikta inte sprutpistolen mot människor eller djur

Não direccionar a pistola de pintura para pessoas ou animais

Nicht in den Spritzstrahl fassen

Do not reach into the spray jet

Ne pas toucher au jet

No interceptar el chorro de pulverización

Не прикасайтесь к струе распыляемого материала

Püskürtme huzmesine elinizi sokmayın

Nie sięgać w strumień rozpryskowy

Stick inte in händerna i sprutstrålen

Não tocar no jacto de pulverização

0

bar

psi

SOS

Im Notfall: Energiezufuhr absperren und Druck entlasten

In an emergency: Shut off power supply and relieve pressure

En cas d‘urgence : Bloquer l‘alimentation en énergie et relâcher la pression

En caso de emergencia: Cortar el suministro de energía y despresurizar el sistema

В экстренной ситуации: Заблокируйте подачу тока и сбросьте давление

Acil durumda: Enerji beslemesini kesin ve basıncı azaltın

W sytuacji awaryjnej: Zablokować dopływ energii i zredukować ciśnienie

Vid nödfall: Stäng av strömtillförsel och töm ut trycket

Em caso de emergência: Bloquear a alimentação de energia e despressurizar

In EX-Zonen nur Maschinen mit EX-Kennzeichnung betreiben

In EX zones, only operate machinery with EX labelling

Dans les zones soumises à un risque d‘explosion, exploiter uniquement

des machines présentant un marquage EX

En zonas con riesgo de explosión poner en servicio únicamente máquinas

con identicación EX

Во взрывоопасных зонах используйте только машины с маркировкой

взрывозащиты

EX bölgelerinde sadece EX işaretli makineleri işletin

W strefach zagrożonych wybuchem eksploatować wyłącznie maszyny z oznaczeniem EX

Endast EX-märkta maskiner får användas i EX-zoner

Nas zonas EX apenas operar máquinas com a identicação EX

bar

psi

max.

Zubehöre /Ersatzteile: max. Betriebsdruck der Maschine beachten!

Accessories / spare parts: Observe the max. operating pressure of the machine!

Accessoires/pièces de rechange : respecter pression de service max. de la machine !

Accesorios/piezas de repuesto: ¡Observar la presión de servicio máx. de la máquina!

Комплектующие / запчасти: учитывайте макс. рабочее давление машины!

Aksesuar / yedek parçalar: Makinenin maks. işletim basıncını dikkate alın!

Wyposażenie / części zamienne: przestrzegać maks. ciśnienia roboczego maszyny!

Tillbehör/reservdelar: ge akt på maskinens max. arbetstryck!

Acessórios / peças de substituição: ter em atenção a pressão de serviço máx. da máquina!

Fig. 1: Safety card

2.4 Safety equipment

WARNING

If safety equipment is missing or is not fully functional, the operating safety of

the machine is not guaranteed!

➤Put the machine out of operation immediately if you detect safety equip-

ment defects or any other faults on the machine.

➤Only put the machine back into operation once the faults have been fully

rectied.

The machine is equipped with the following safety equipment:

➤Safety valves

➤Compressed air shut-off valves

➤Ground cable

Check the safety equipment on the machine:

➤Prior to starting up

➤Always prior to starting work

➤After all set-up work

➤After all cleaning, maintenance and repair work