5. Cleaning and sterilizing:

Allow sufficient time for burner orifice (7, 7a) to cool down before disassembling or cleaning

the burner head. Check the unit is disconnected and that the gas supply is turned off at the

mains. The burner can be cleaned with customary commercial disinfectants. Additionally, it

is possible to remove the burner head and to clean it separately.

The stainless steel and glass construction allow 100% UV-radiation sterilization and short

time surface flame sterilization.

Attention: Because of the connectors at the back of the unit the backside should not be

sterilized with a flame.

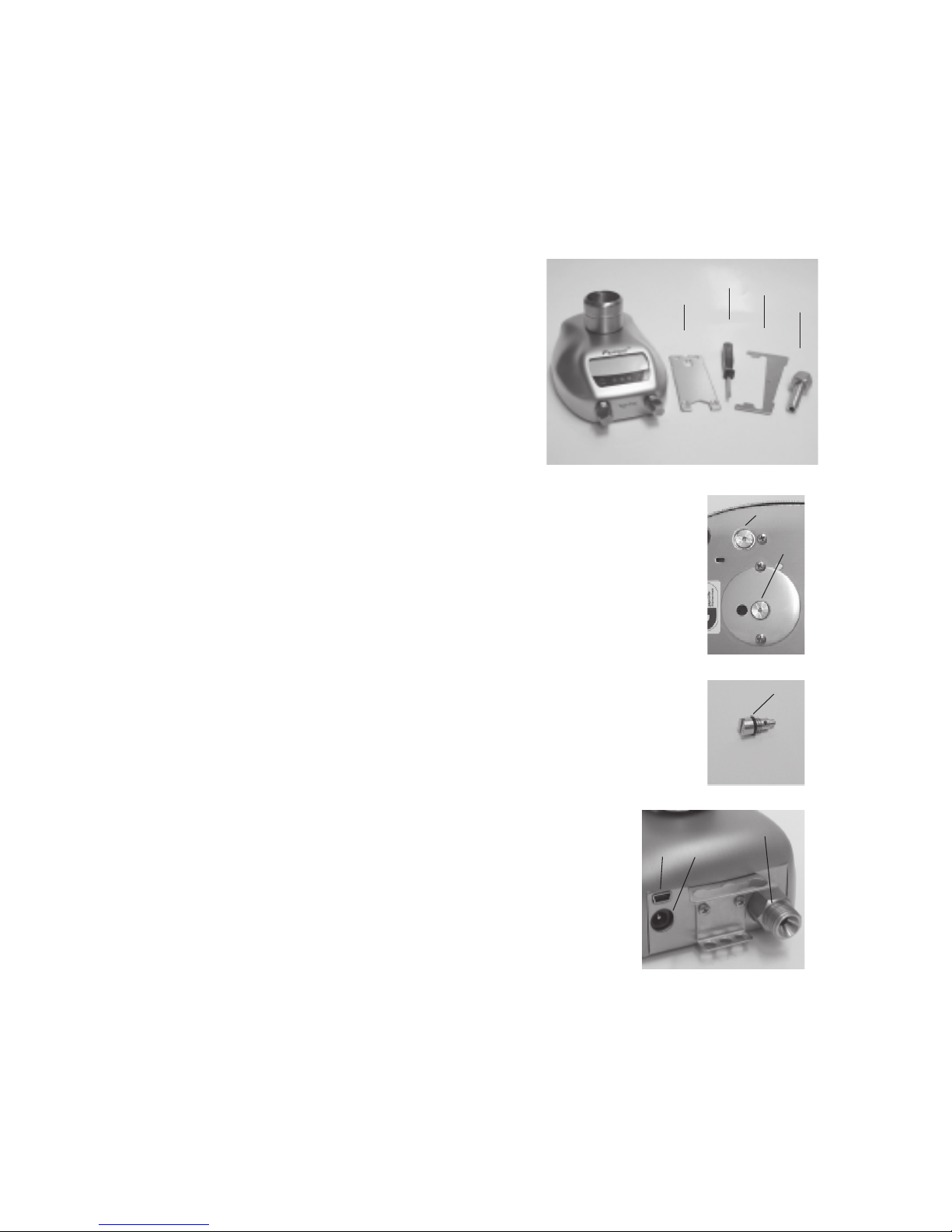

5.1 Burner head disassembly and cleaning:

Allow sufficient time for burner orifice (7,7a) to cool down

before disassembling or cleaning the burner head.

Check the unit is turned off, that the gas supply is

turned off at the mains. Clean the burner head with

customary commercial disinfectants, sterilize it in

an autoclave or wash it in a dishwasher. To remove

the burner head proceed as follows:

Unscrew the burner head screw (12) completely with

the included screwdriver. Turn approx. 8 revolutions

to the left. Now remove the burner head from the device

by pulling it upwards. Reinstallation is performed

in the reverse sequence.

The dismounted burner head can be even dismantled into the individual components for in-

depth cleaning: Unscrew both screws (12a) and take off the base plate (12b) of the burner

head which was fixed by the two screws (12a). After the base plate is removed both electrodes

can be pulled out for seperate cleaning. Reinstallation is performed in the reverse sequence.

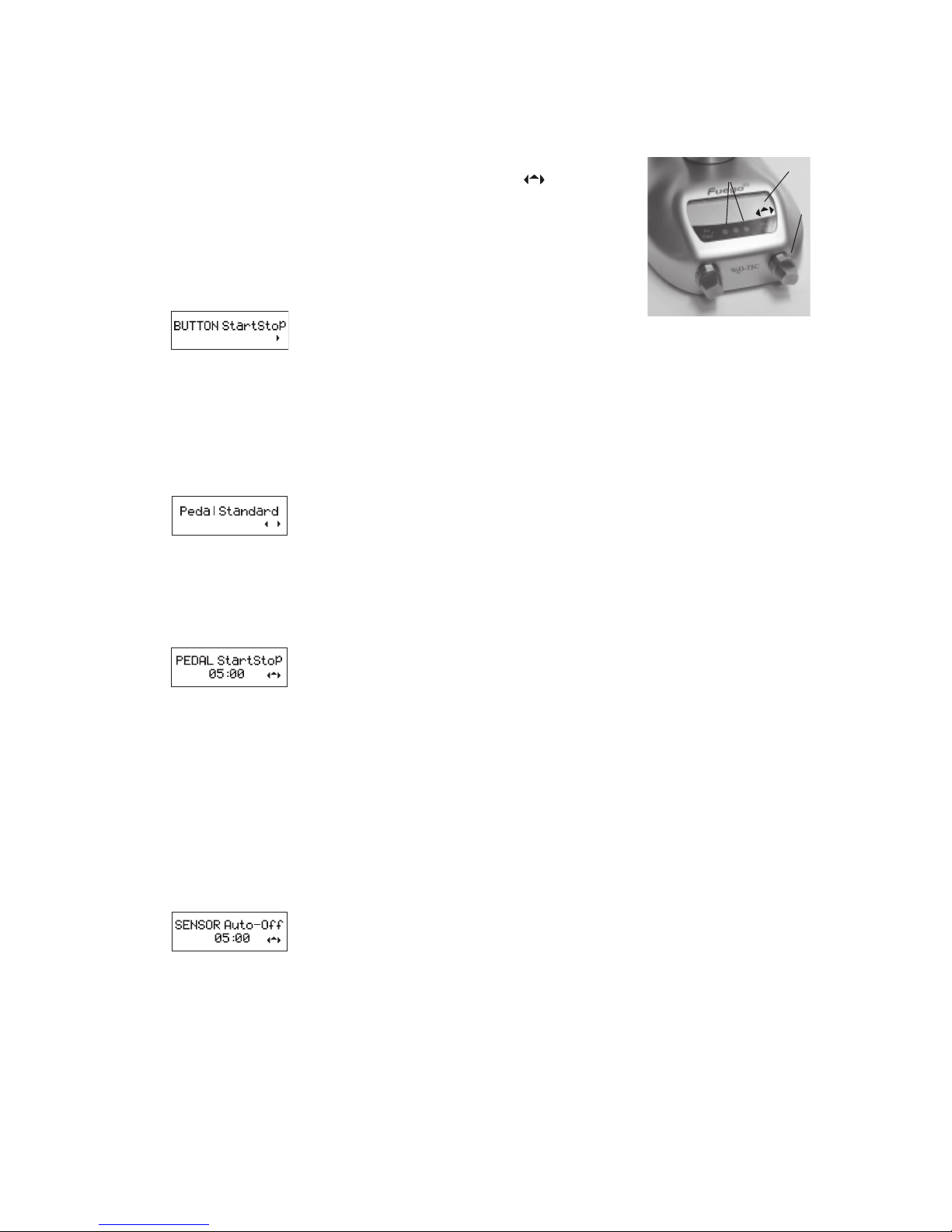

5.2 Burner shaft cleaning:

Unscrew the screw (18) completely

with the included screwdriver. Take off the cover (17)

of the burner shaft. Now the burner shaft can

be cleaned or solid substances which have fallen

into the unit can be removed. Reinstallation is

performed in the reverse sequence. Take care that

the notch of the cover fits to the screw (18a).

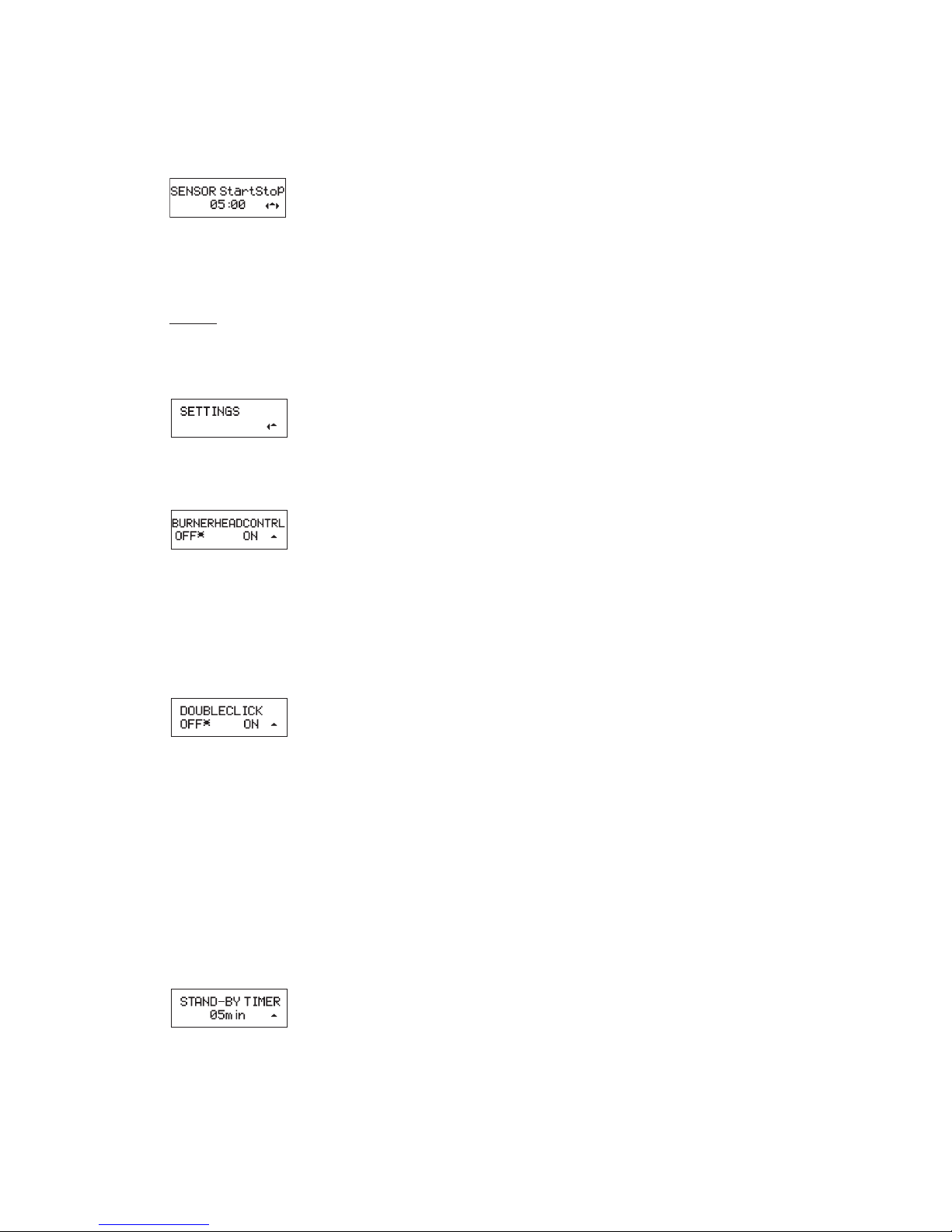

6. Turbo flame:

If the cover of the burner shaft (17) is removed the

flame is extremely firm and consistent. To take off

the cover of the burner shaft unscrew the screw (18)

completely with the included screwdriver. With an open burner shaft the intensity of the

flame cannot be adjusted by the air knob any longer. During the use of the turbo flame most

of the needed air is taken inside through the open burner shaft. Remounting the cover of

burner shaft. (see paragraph 5.2)

7. Tilt adjustment:

Insert the tilt adjustment (23) into the slots (19)

at the bottom of the unit. The tilt-adjustment can

be used to the left or right side to protect the

burning chamber from contamination when

working with liquids.

23

7a 7

12

12a 12b

18a

17

18

18a open

burner

shaft